An electric high-temperature gate valve with a limit mechanism

A technology of high temperature gate valve and limit mechanism, which is applied to sliding valves, valve devices, mechanical equipment, etc., can solve the safety hazards of catalytic cracking devices, the inability of electric high temperature gate valves to open, and the valve plate wedge dead after clearance, so as to facilitate disassembly and sewage discharge. , The effect of preventing the valve plate from passing through and facilitating debugging and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

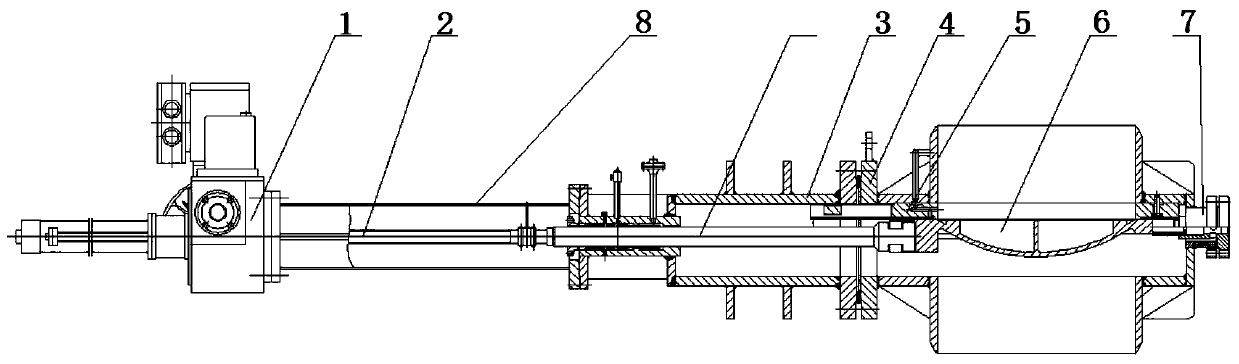

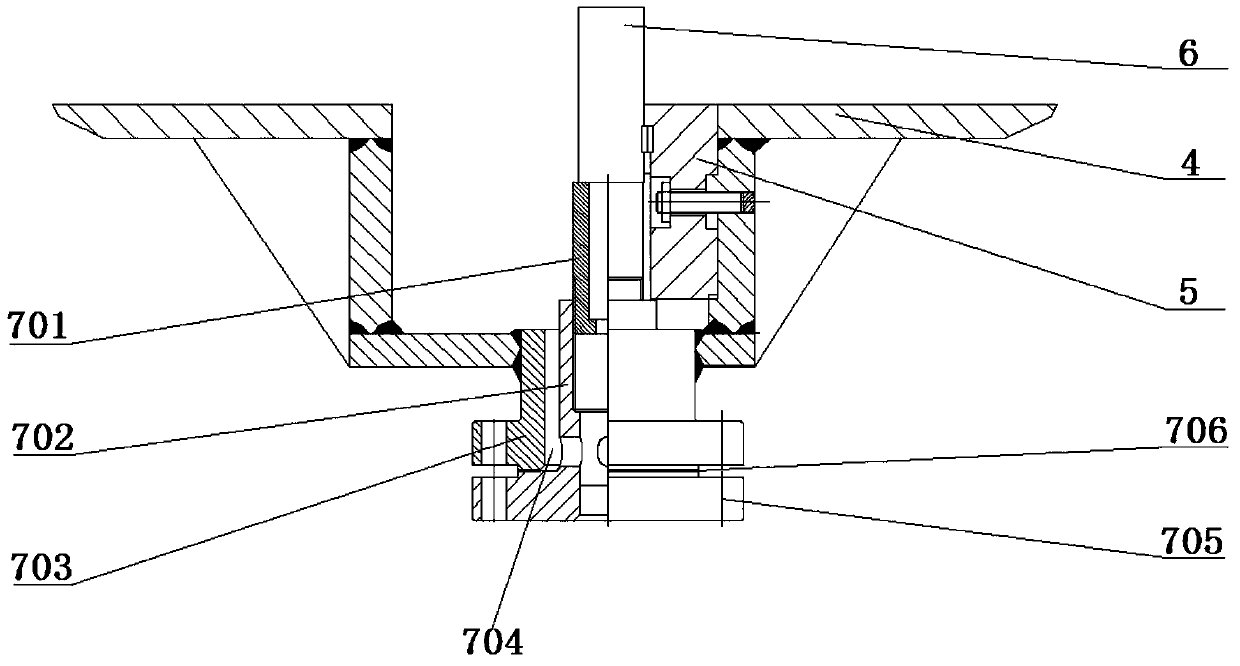

[0040] as attached figure 1 and attached figure 2 As shown, the embodiment of the present invention provides an electric high temperature gate valve with a limit mechanism, the electric high temperature gate valve includes: electric actuator 1, valve stem 2, valve cover 3, valve body 4, valve seat ring 5, valve plate 6. Further, the electric high-temperature gate valve also includes a limit mechanism 7, which includes a limit screw 701, a necked connection flange 702, and a necked condensation drain flange 703.

[0041] One end of the limit screw 701 abuts against the lower end of the valve plate 6 at the fully closed position, and the other end is threadedly connected to the neck of the neck flange 702 . The neck of the necked con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com