Thermal boiler

A boiler and thermal technology, applied in the field of thermal boilers, can solve the problems of large flue gas resistance horizontal rectangular reverse combustion boiler wall pressure, and achieve the effects of prolonging residence time, fully burning, and improving combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

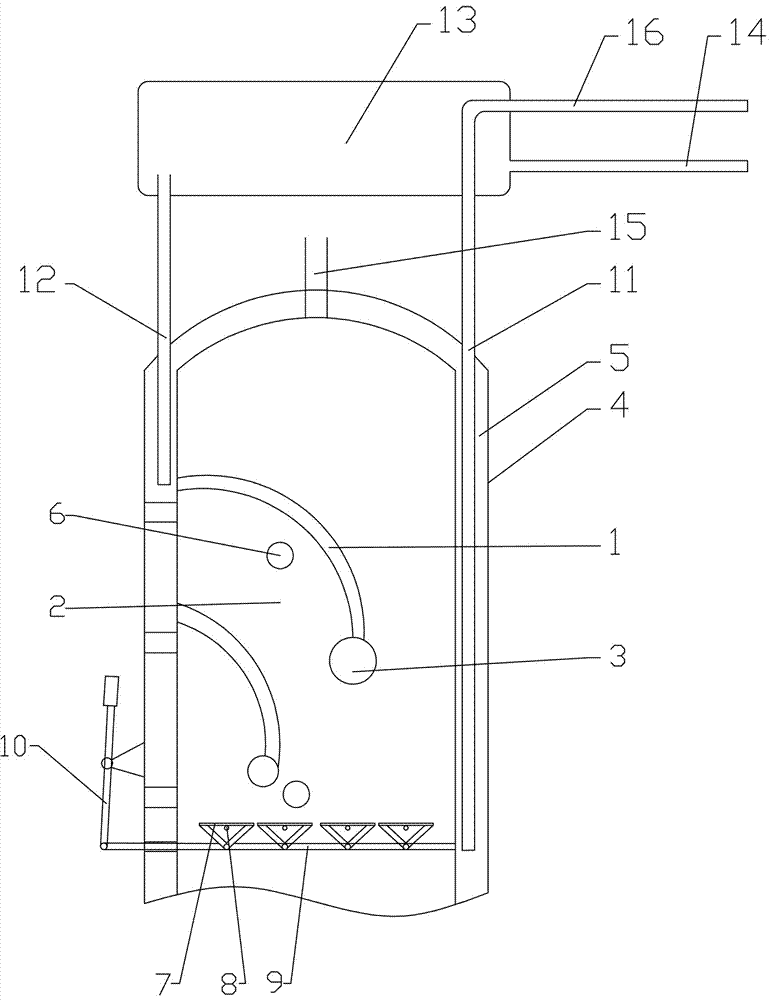

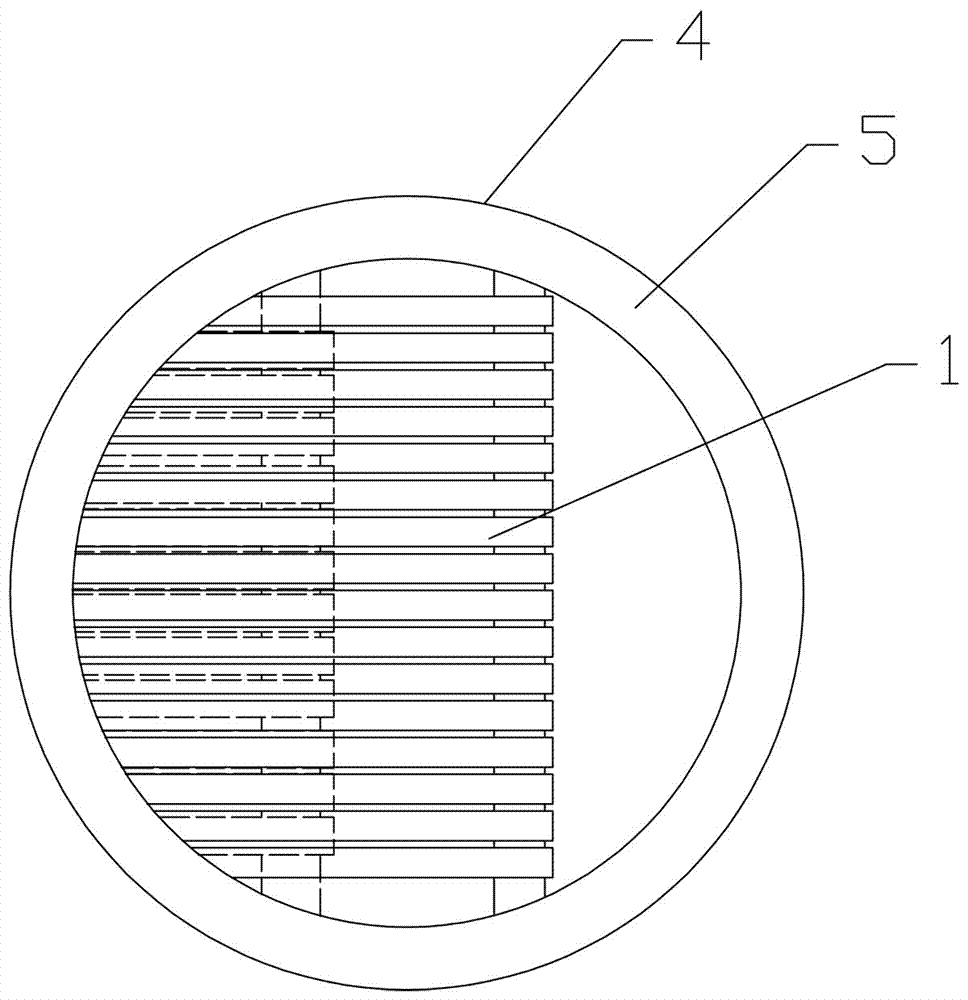

[0016] In the thermal boiler of the utility model, the furnace wall is a hollow water-circulating cavity. The furnace is provided with side-by-side elbows. The inner side of the side-by-side elbows and the furnace wall enclose at least one combustion chamber, and the upper part of the side-by-side elbow leads out from the furnace wall. , The side-by-side elbows are collected in the manifold at the lower part, and both sides of the manifold are opened into the furnace wall. The flame-retardant material is arranged between the side-by-side elbows to separate the upper and side of the combustion chamber from the upper part of the furnace. Fuel input ports are provided on both sides of the furnace wall and the front furnace wall.

[0017] In order to achieve the required combustion temperature in the boiler, only high combustion value fuel can be put in, and the suitable fuel is relatively single. By adopting the multi-combustion chamber structure of the present invention, it is poss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com