Explosive charging method for improving shaping of horizontal stratum tunnel

A rock layer and tunnel technology, which is applied in the field of charging for improving the formation of horizontal rock layer tunnels, can solve the problems of poor interlayer bonding force of large-section horizontal rock layers, threatening the safety of tunnel construction personnel, and poor smooth blasting effect. Guarantee construction quality and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The invention relates to a charge method for improving the formation of horizontal rock tunnels, through which the molding quality of horizontal rock tunnels after blasting can be improved, the over- and under-excavation of horizontal rock tunnels can be reduced, and the disturbance and damage to surrounding rocks can be reduced , save the increased engineering quantity and cost due to over-excavation or under-excavation, shorten the construction period, and ensure the construction quality and construction safety.

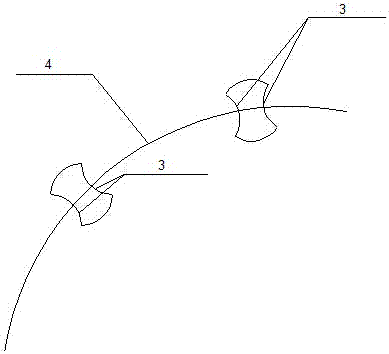

[0027] The present invention uses PVC pipes, emulsified explosives, the excavation contour line of the tunnel in the horizontal rock stratum and the positions of several blastholes on the excavation contour line.

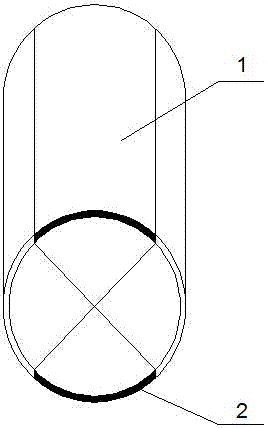

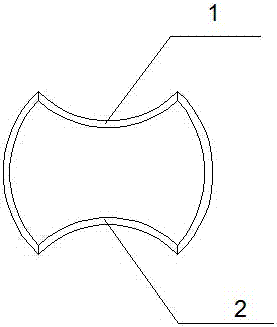

[0028] combine Figure 1-2 , the present invention cuts a PVC pipe with an outer diameter of 32mm and a wall thickness of 1.4±0.3mm into quarters. The wall thickness d of the PVC pipe is determined by the product. Ring 1, right ring, lower ring 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com