Surface light source device, side entering type backlight module and display device

A technology of surface light source and luminous source, applied in the field of light source and display, can solve the problem of light leakage, etc., and achieve the effect of reducing thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings.

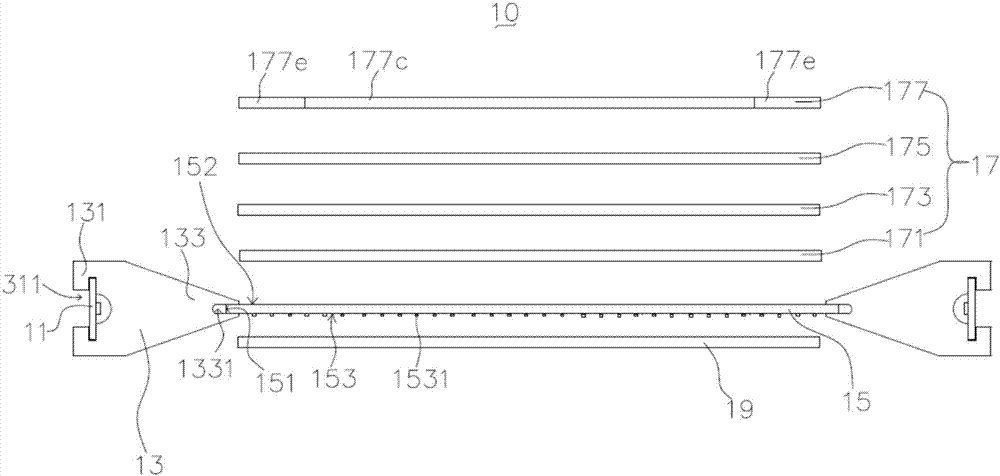

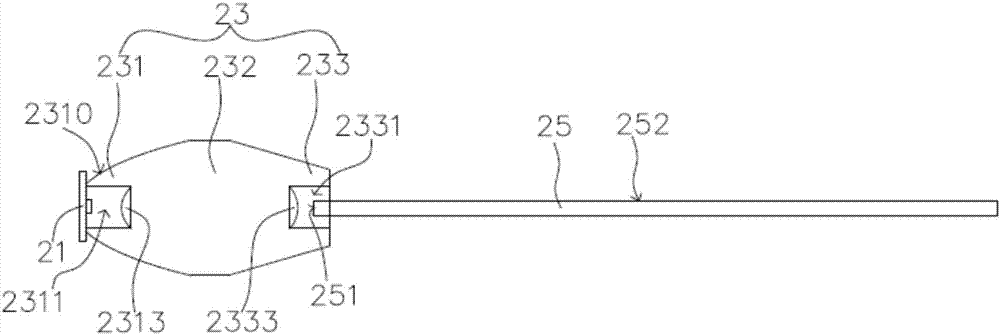

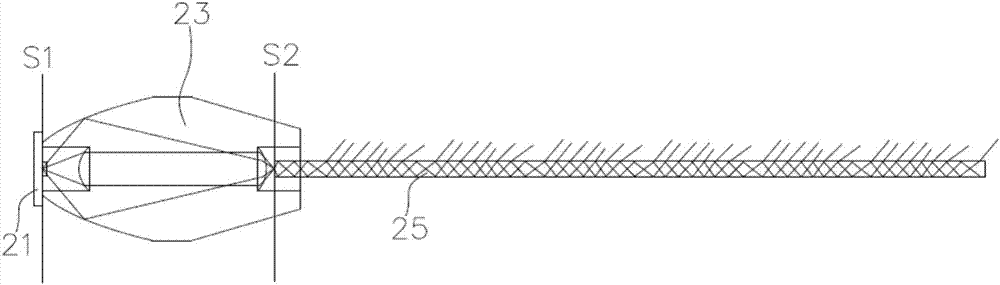

[0024] see figure 1 , the edge-type backlight module 10 proposed by the first embodiment of the present invention includes: a light source 11 , a light guide column 13 , a light guide film 15 , an optical film set 17 and a reflection sheet 19 . The light emitting source 11, the light guide column 13 and the light guide film 15 together constitute a surface light source device, wherein the light guide column 13 and the light guide film 15 are separate parts and can be assembled together.

[0025] Based on the above, the light emitting source 11 is, for example, an LED light bar, which includes a strip-shaped PCB board and a plurality of LED lights arranged on the PCB board. Certainly, the light source 11 may also include a strip-shaped...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com