A back-mounted SMD LED dedicated to transparent substrates

A transparent substrate and back-mounted technology, which is applied to the components of lighting devices, lighting devices, lighting and heating equipment, etc., can solve the problems of outstanding durability, affecting the light transmittance of glass substrates, and rubbing off cleaning tools. To achieve the effect of easy wiring, avoid discoloration and avoid short circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

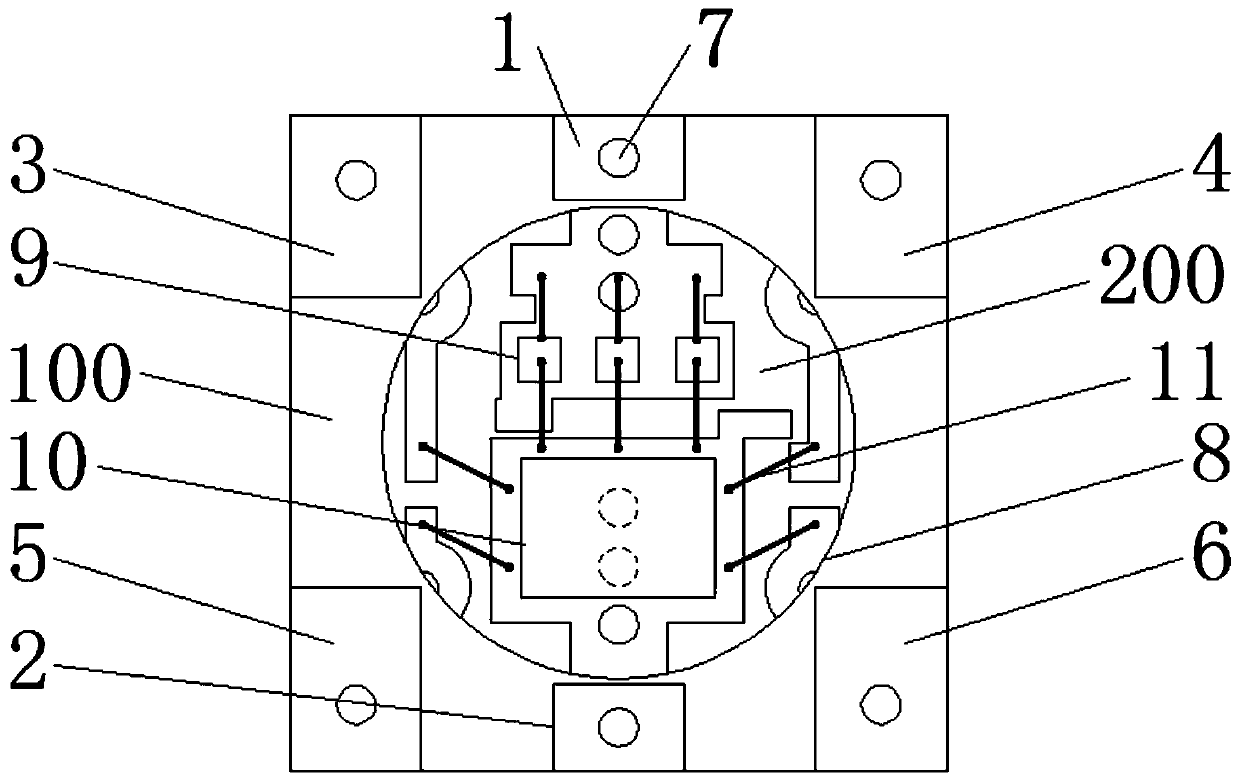

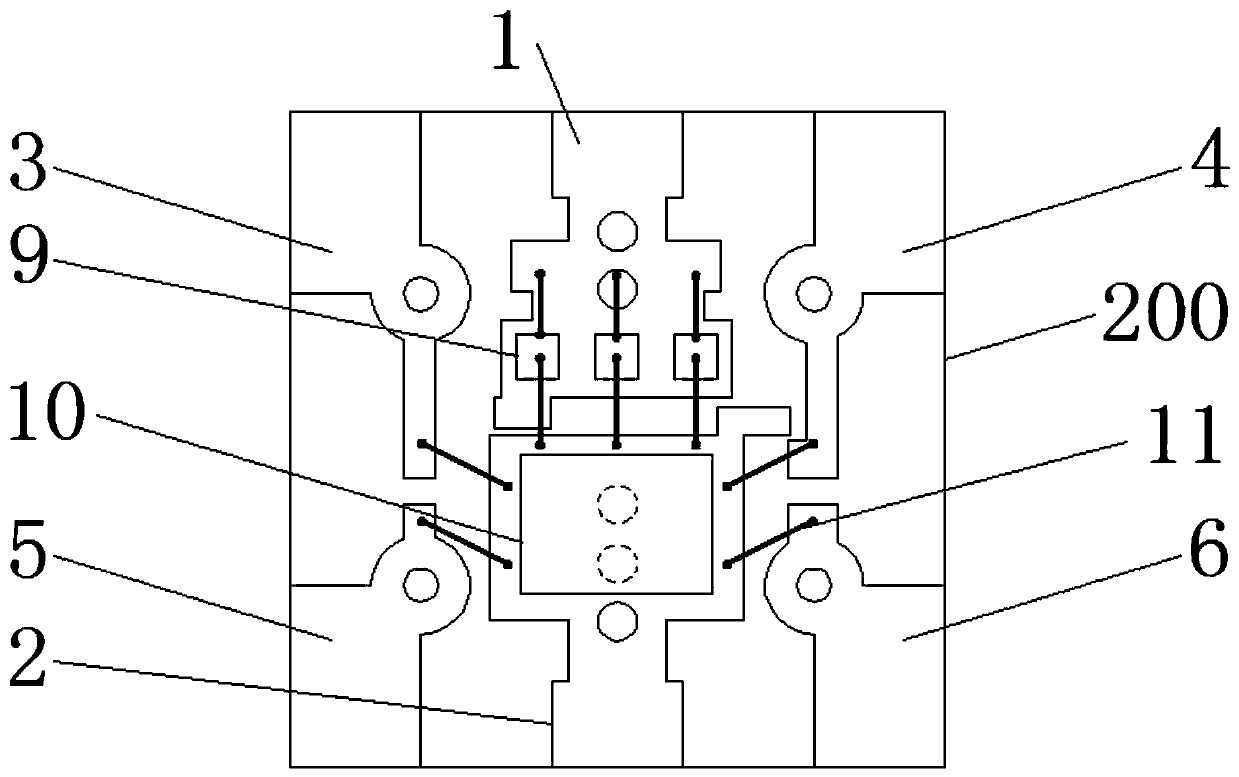

[0016] Hereinafter, the present invention will be described in detail by taking the SMD LED with built-in IC chip as an example with reference to the drawings and embodiments, and the content of the present invention is not limited to the following embodiments.

[0017] see figure 1 , the back-mounted SMD LED dedicated to transparent substrates provided by the present invention is a double-layer structure, including an upper layer 100 and a lower layer 200; On the lower layer 200, the central through hole 8 is opposite to the central area of the lower layer 200. The central through hole 8 is filled with epoxy resin, and the wall of the central through hole 8 of the upper layer 100 is coated with reflective paint. The upper layer 100 and the lower layer 200 are connected through pads and packaged as a whole through epoxy resin;

[0018] The upper layer 100 is a double-sided board, and its front and back sides are provided with 6 welding pads around the sides. Through the vi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com