A kind of preparation method of proton exchange membrane with hydrophilic/hydrophobic interpenetrating network structure

An interpenetrating network structure, proton exchange membrane technology, applied in the field of proton exchange membrane fuel cell components, can solve the problems of increasing battery weight, complexity and cost, hindering the application of proton exchange polymer membranes, and decreasing proton conductivity. Good thermodynamic stability, promoting compatibility, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] (1) Dissolve 3.88g of 11-bromo-1-undecanol in dissolved anhydrous tetrahydrofuran, add 1.60g of triethylamine to it under an ice-water bath and mix thoroughly, then, under the protection of nitrogen, add Add 1.49g of methacryloyl chloride dropwise, and react at room temperature (25°C) for 48 hours; remove the solvent, extract the product with dichloromethane, wash with water, dry, and elute with a volume ratio of petroleum ether and acetone of 1:1 Neutral alumina (Al 2 o 3 ) column to collect the first product;

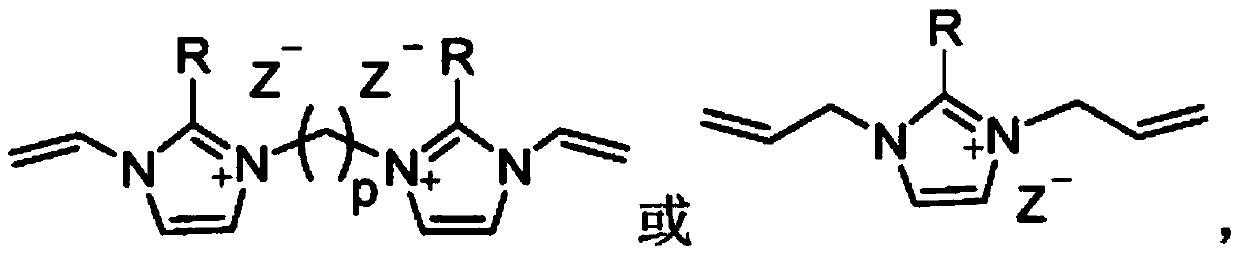

[0019] (2) Under the protection of nitrogen, mix 3.28g of the first product collected in step (1) with 0.92g of 1-methylimidazole, react at 40°C for 48 hours, purify the product by diethyl ether precipitation, and obtain after drying The ionic liquid auxiliary agent required by this scheme is 3.23g, and the chemical structural formula is

[0020] Will 1.50g, 1.40g, the above 2.00g, Mix 0.30g and 0.05g of benzoin ethyl ether evenly, apply it on the ...

Embodiment 2

[0023] The preparation method of ionic liquid additive refers to Example 1;

[0024] Will 1.00g, 1.40g, 2.30g, Mix 0.40g and 0.05g of benzoin ethyl ether evenly, apply it on the mold, irradiate with ultraviolet light for 30min, and polymerize in situ to form a film.

[0025] The electrical conductivity of the proton exchange membrane obtained in this example reaches 1.01×10 at 150°C -2 S cm -1 .

Embodiment 3

[0027] The preparation method of ionic liquid additive refers to Example 1;

[0028] Will 0.90g, 1.10g, 2.50g, Mix 0.50g and 0.06g of azobisisobutyronitrile evenly, apply on the mold, and polymerize at 75°C for 6 hours to form a film.

[0029] The electrical conductivity of the proton exchange membrane obtained in this example reaches 1.13×10 at 150°C -2 S cm -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com