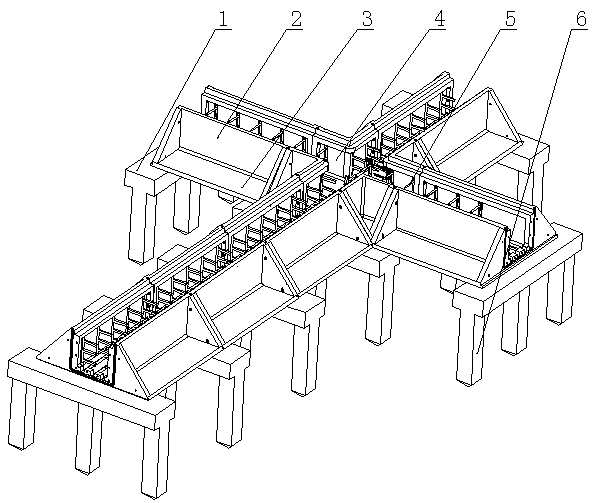

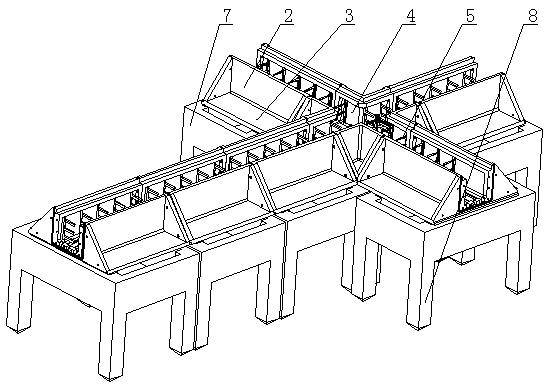

Assembled open cable trench

A cable trench and assembly technology, which is applied in the direction of cable installation, ground cable installation, electrical components, etc., can solve the problems of cable trench inclination, settlement, deformation, etc., and achieve the effect of extremely short construction period, convenient construction and resource saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] As shown in the figure, the prefabricated open cable trench includes underground infrastructure and cable trench assembly, and the cable trench assembly is set above the underground infrastructure. In the cable trench assembly, a U-shaped seal is embedded between the cable trench 2 and the cable trench 2 or between the cable trench 2 and the intercommunicating cable trench 4, and is connected into one body after being fixed by knocking screws; the cable trench 2 is equipped with a cable bracket 5, It is used for supporting cables; a waterproof cover is provided above the cable trench 2.

[0028] The prefabricated cable trench 2 is industrial-shaped, and it is equipped with a bracket of a waterproof cover plate, and it is equipped with an anti-settling, inclined extension edge 3, and the two ends of the anti-settling and inclined extension edge 3 are provided with triangular edges and the body of the cable trench 2 Connection, the end face of the triangular side is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com