Water yield proportion adjustment devices

A technology of proportional adjustment and water output, applied in the direction of spraying device, spraying device, etc., can solve the problems of inability to realize independent real-time change of spray height of sprinkler head, stepless adjustment of spray height of sprinkler head, high cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

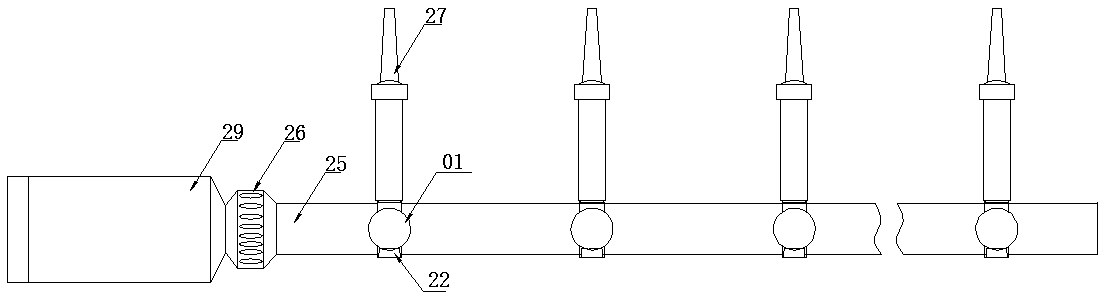

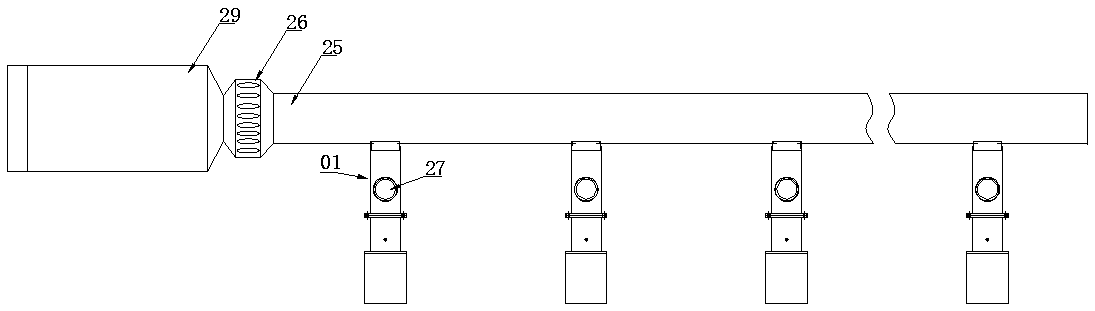

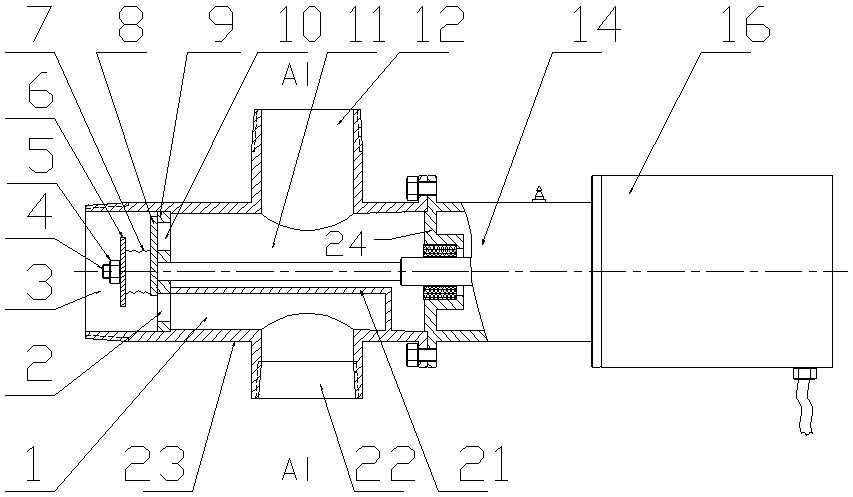

[0021] In order to make the technical solution of the present invention clearer, the following is attached Figure 1 to 8 , The present invention will be described in detail. It should be understood that the specific implementations described in this specification are only for explaining the present invention and not for limiting the protection scope of the present invention.

[0022] The present invention is a water output proportional adjusting device. There are at least two water output proportional adjusting devices 01. Each water output proportional adjusting device 01 includes a cavity surrounded by a housing 23, and one end of the cavity is provided with There is a water inlet 3, the other end of the cavity is provided with an end cap 24, and a water blocking plate 9 for blocking water inflow is provided at the water inlet 3 of the cavity. A water blocking plate 21 connects the water blocking plate 9 with the end The cavity between the cover 24 is divided into a water out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com