Water retaining part used for ceramic tile cutter

A technology for water-retaining parts and cutting machines, which is applied to work accessories, stone processing tools, manufacturing tools, etc., and can solve problems such as the influence of water-retaining effects and the fatigue of material properties of flexible water-retaining parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

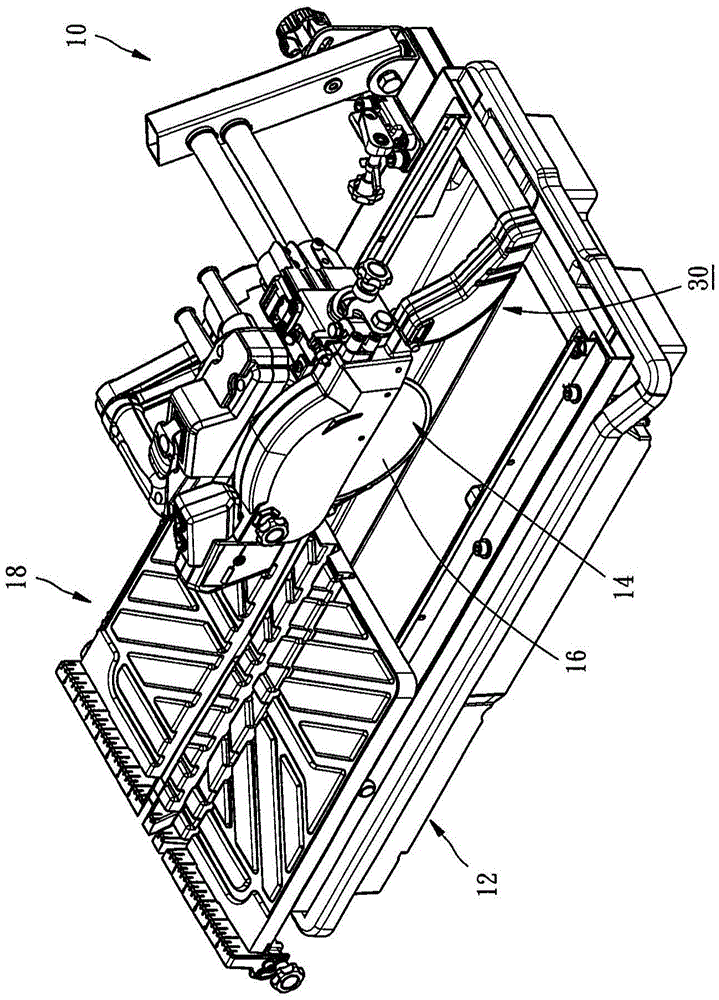

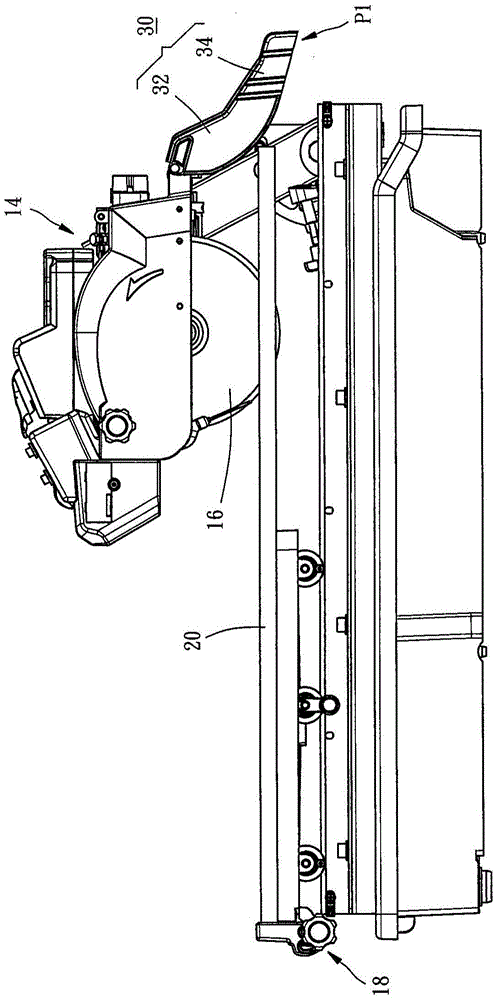

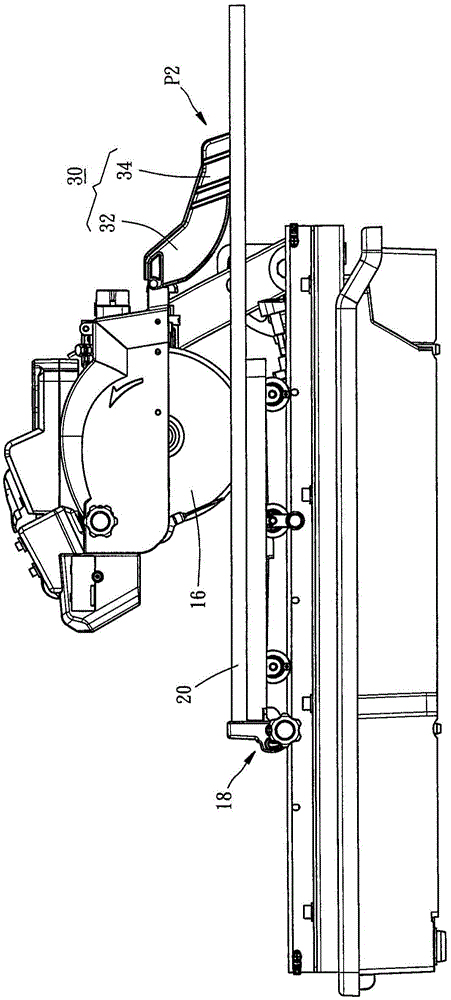

[0013] Please see first figure 1 , the tile cutting machine 10 shown in the figure includes a base 12, a saw blade seat 14, a saw blade 16, and a working platform 18, wherein: the base 12 is used to erect on the ground or a tripod, saw The blade seat 14 is arranged on one end of the base 12, the saw blade 16 is pivotally arranged on the saw blade seat 14, and the working platform 18 is slidably arranged on the base 12 for moving a workpiece 20 carried toward the side of the saw blade 16. Push in the same direction so that the saw blade 16 can cut the workpiece 20 .

[0014] see again figure 1 and figure 2 The water retaining member 30 of the present invention is located directly behind the saw blade 16 and has a pivot joint 32 and a water retaining portion 34. The top end of the pivot joint 32 is pivotably arranged at the rear end of the saw blade seat 14, so that The water retaining member 30 can pivot up and down relative to the saw blade base 14 , and the water retainin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com