Superposed beam cable-stayed bridge deck crane method applied in mountainous area

A machine method and technology in mountainous areas, which is applied in the field of deck crane method of superimposed beam cable-stayed bridges in mountainous areas, can solve the problems of the narrow site of the main tower attachment, the large amount of construction works, and the long construction period, so as to reduce the construction cost and reduce the construction cost. The effect of high quality and saving construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

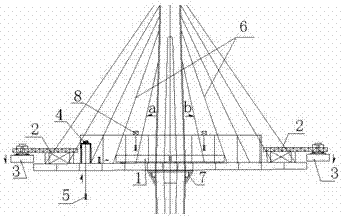

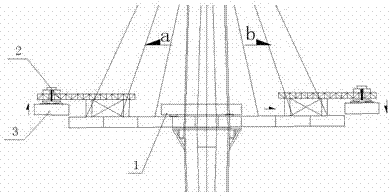

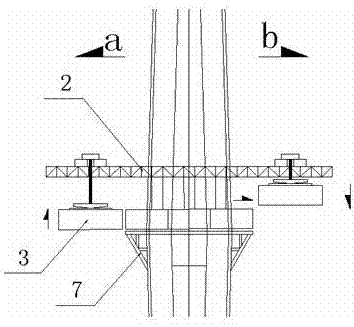

[0025] A bridge deck crane method for composite girder cable-stayed bridges in mountainous areas, which consists of Figure 1-6 As shown, it specifically includes the following steps:

[0026] (a) Install steel girder 0﹟ section 31;

[0027] (b) A plurality of steel main girders 3 are assembled with steel main beam parts 5 at the position of the side-span platform; the side-span platform is an assembled platform with steel main beam parts 5 at the position of the side-span;

[0028] (c) From the side span, take the 0﹟ section 31 of the steel main beam as the starting point, sequentially hoist, transport, and install the side span side and mid-span side steel main beam (3) 1--N﹟ section, and install the stay cables in sequence 6, where N≥2;

[0029] (d) Set up the bridge deck steel main girder pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com