In-situ heating method of coal bed gas thermal exploitation

A technology of thermal mining and coalbed methane, which is applied in the direction of mining fluid, earthwork drilling, wellbore/well components, etc., and can solve problems such as difficult construction and impossibility of implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

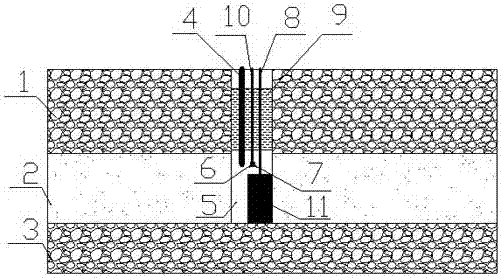

[0031] Such as figure 1 As shown, in a nearly horizontal single coal seam 2 with a thickness of 10m and a buried depth of 300m, the present invention is used to heat the coal seam in situ.

[0032] A method for in-situ heating of thermal mining of coalbed methane, the specific steps of which are as follows:

[0033] ① After hydraulic fracturing of the coal seam 2, vertical drilling 5 is carried out on the ground to the coal seam floor 3;

[0034] ② Place the electric heating rod 11 at the bottom of the well along the vertical drilling 5, and the electric heating rod 11 is connected to the ground with the No. 1 cable 8 sealed by a high-temperature-resistant rubber packer;

[0035] ③Arranging the water-injection steel pipe 4 with an inner diameter of 30-60 mm in the drilling well from the ground, so that the nozzle is in the middle of the coal seam at a position 1 / 2 to 2 / 3 of the thickness of the coal seam from the bottom of the coal seam;

[0036] ④ Place the temperature sens...

Embodiment 2

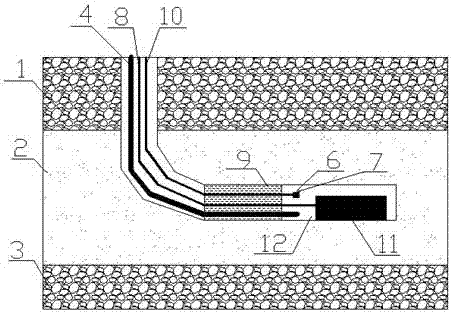

[0043] Such as figure 2 As shown, in a nearly horizontal single coal seam 2 with a thickness of 10m and a buried depth of 300m, the present invention is used to heat the coal seam in situ.

[0044] A method for in-situ heating of thermal mining of coalbed methane, the specific steps of which are as follows:

[0045] ① After hydraulic fracturing of coal seam 2, horizontal drilling 12 is carried out on the ground to the middle of the coal seam;

[0046] ② Place the electric heating rod 11 in the horizontal drilling along the horizontal drilling 12, and the electric heating rod 11 is connected to the ground with the No. 1 cable 8 sealed by a high-temperature resistant rubber packer;

[0047] ③ Arrange the water injection steel pipe 5 with an inner diameter of 30-60mm in the well from the ground, so that the nozzle is placed near the electric heating rod 11;

[0048] ④ Place the temperature sensor 6 and the pressure sensor 7 at the same position as the water injection steel pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com