In-situ rapid self-propagating heating refractory metal explosive welding device and process

A technology of refractory metal and explosive welding, applied in metal processing equipment, welding equipment, manufacturing tools, etc., can solve the problems of inconvenient use of electricity, low heating efficiency, and difficulty in controlling the temperature of heated metal, so as to avoid a large number of accumulations and improve heating efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

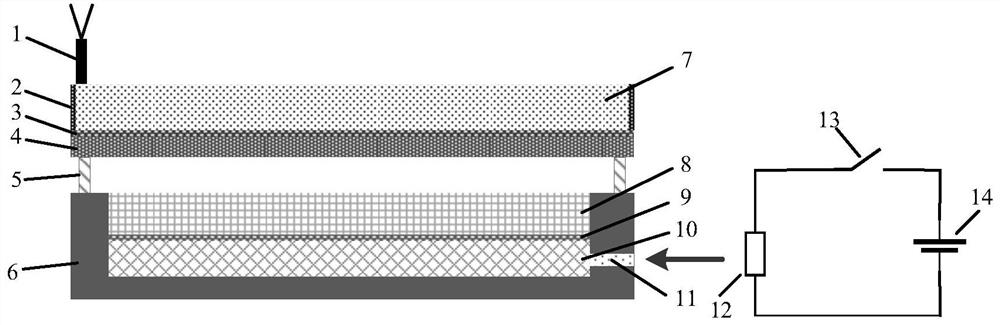

[0028] The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0029] The principle of the present invention is: refractory metals (such as tungsten, molybdenum, etc.) generally have a body-centered cubic (BCC) structure, and BCC metals have a "ductile-brittle transition temperature", that is, they are in a brittle state at room temperature, and will become brittle after reaching a certain temperature. into a resilient state. In the conventional explosive welding of refractory metals, due to the high brittleness of refractory metals, the high strain rate generated by the high-speed collision between the flying plate and the substrate will cause cracks in the refractory metals, and the refractory metals are heated before explosive welding to make them Breaking through the "ductile-brittle transition temperature", explosive welding of refractory metals in a ductile state can effectively reduce or eliminate cracks and ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com