Micropore and microcrack composite toughening millimeter thick ceramic coating and preparation method

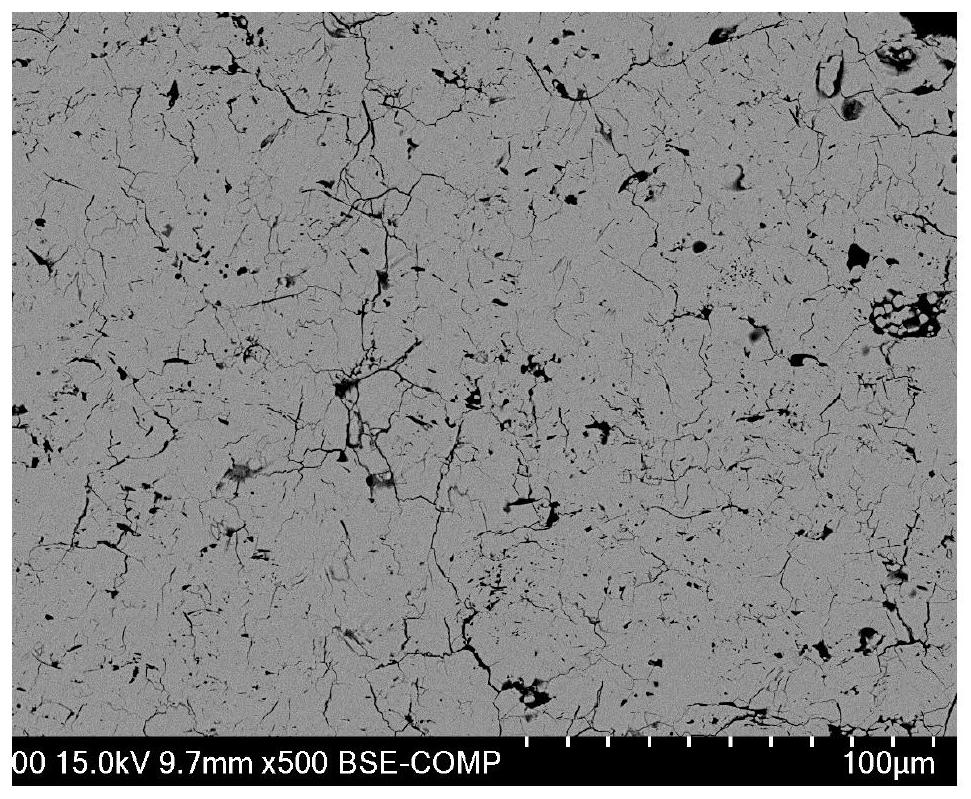

A ceramic coating and micro-crack technology, applied in coating, metal material coating process, melt spraying and other directions, can solve the problems of limiting the performance improvement of ceramic coating, large size of holes and cracks, and low particle flying speed. Achieve the effect of comprehensive mechanical properties and industrial application range improvement, large brittleness, and inhibition of crack growth behavior

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] In this example, the GH4169 nickel-based superalloy is used as the matrix, the size is Φ25.4×10mm, and the mass percentage includes: ≤0.08%C, 17%Cr, 55%Ni, 1.0%Co, 2.8%Mo, 0.6%Al , 0.75% Ti and the balance Fe.

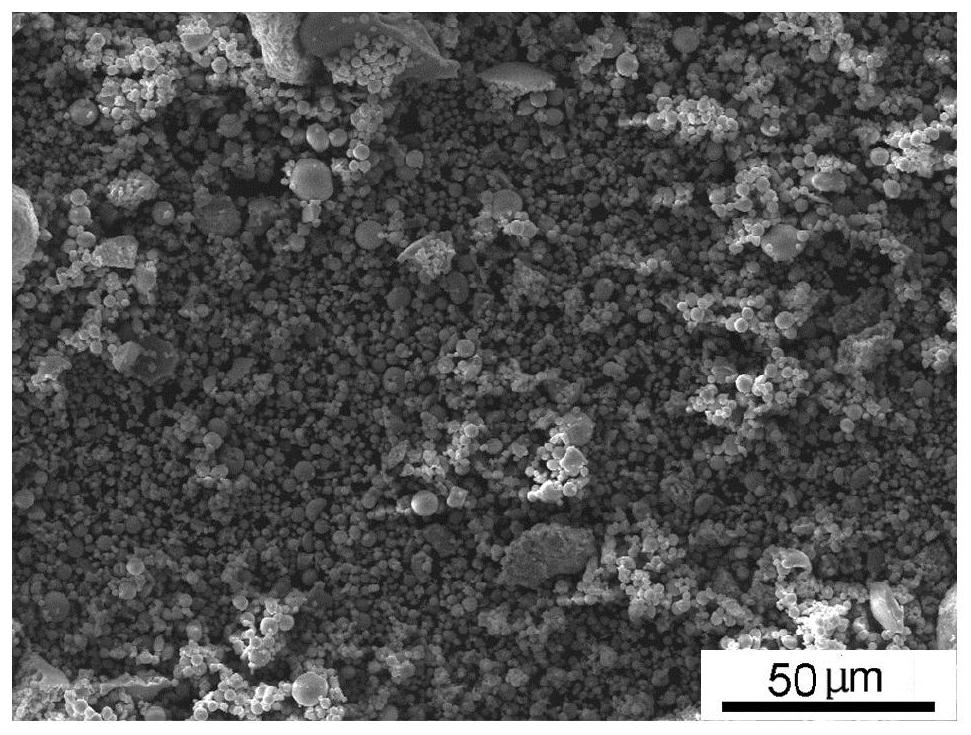

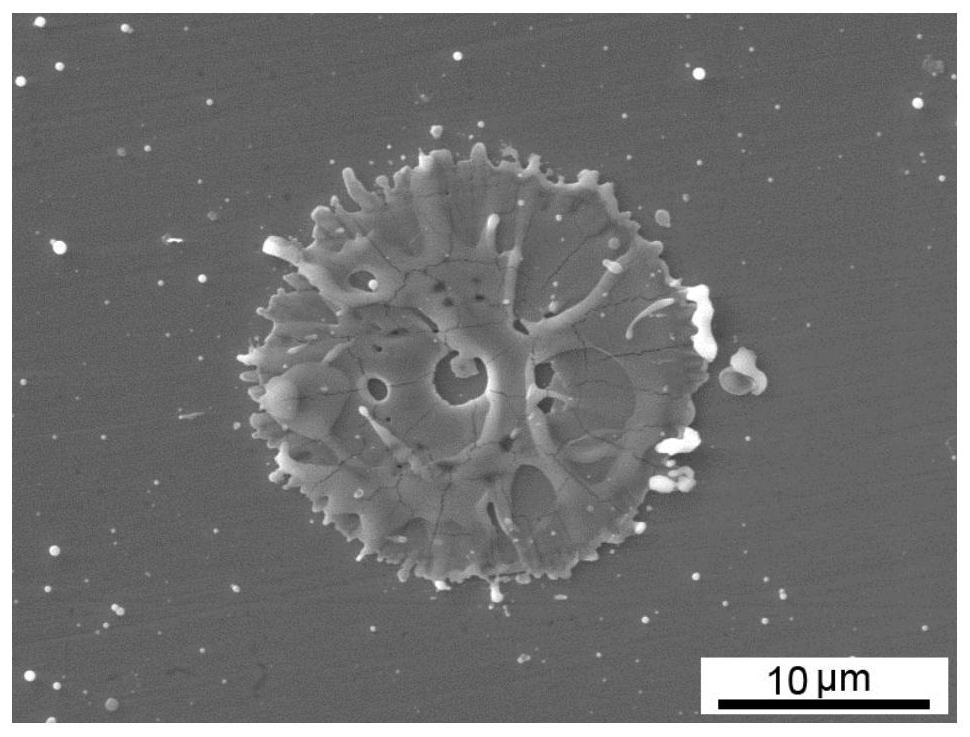

[0043] The oxide ceramic powder is zirconia powder, and the particle size of the oxide ceramic powder is in the range of 10-90 μm.

[0044] The specific implementation steps of preparing micropore and microcrack composite toughening millimeter-thick ceramic coating by high-energy plasma spraying technology are as follows:

[0045] 1) Substrate surface pretreatment

[0046] The surface of the alloy disc is first degreasing, decontaminating, grinding and derusting, then ultrasonically cleaned with acetone, dried in a drying box after cleaning, and finally sandblasted with white corundum (#24), which is rough after sandblasting Degree Ra=10.6 μm.

[0047] 2) The sandblasted substrate is preheated by spray gun preheating, and the temperature is controlled at 180-...

Embodiment 2

[0052] In this embodiment, 2Cr13 martensitic stainless steel is used as the matrix, the size is Φ43×5mm, and the mass percentage includes: 0.25%C, ≤1.0%Si, ≤1.0%Mn, ≤0.035%P, ≤0.03%S, ≤0.6 %Ni, 14%Cr and the balance are Fe.

[0053] The oxide ceramic powder is zirconia powder, and the particle size of the oxide ceramic powder is in the range of 10-90 μm.

[0054] The specific implementation steps of preparing micropore and microcrack composite toughening millimeter-thick ceramic coating by high-energy plasma spraying technology are as follows:

[0055] 1) Substrate surface pretreatment

[0056] The surface of the stainless steel disc as the base material is first degreasing, decontaminating, grinding and derusting, then ultrasonically cleaned with acetone, dried in a drying box after cleaning, and finally sandblasted with white corundum (#24). The roughness after sanding is Ra=11.6 μm.

[0057] 2) The sandblasted substrate is preheated by spray gun preheating, and the tempe...

Embodiment 3

[0063] In this embodiment, 2Cr13 martensitic stainless steel is used as the matrix, the size is Φ43×5mm, and the mass percentage includes: 0.25%C, ≤1.0%Si, ≤1.0%Mn, ≤0.035%P, ≤0.03%S, ≤0.6 %Ni, 14%Cr and the balance are Fe.

[0064] The coating material is zirconia powder, and the particle size of the powder is in the range of 10-90 μm.

[0065] The specific implementation steps of preparing micropore and microcrack composite toughening millimeter-thick ceramic coating by high-energy plasma spraying technology are as follows:

[0066] 1) Substrate surface pretreatment

[0067] The surface of the stainless steel disc as the base material is first degreasing, decontaminating, grinding and derusting, then ultrasonically cleaned with acetone, dried in a drying box after cleaning, and finally sandblasted with white corundum (#24). The roughness after sanding is Ra=11.6 μm.

[0068] 2) The sandblasted substrate is preheated by spray gun preheating, and the temperature is controll...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com