Self-cleaning oil-collecting box for elevator

An oil collecting box and self-cleaning technology, applied in lubricating oil containers, engine components, elevators, etc., can solve the problems of secondary pollution of lubricating oil in the oil collecting box, corrosion and damage of elevator equipment, and pollution of the internal environment of elevator shafts, etc. Ensure continuity and stability, flexible and convenient installation and use, and avoid secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

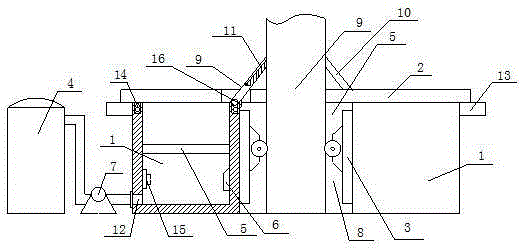

[0015] Such as figure 1 The described self-cleaning elevator oil collection box includes a box body 1, a box cover 2, a positioning seat 3, an oil storage tank 4, a filter device 5, a heating device 6 and a return pump 7, wherein at least one surface of the box body 1 A connection groove 8 is established, and the positioning seat 3 is installed on the outer surface of the connection groove 8 of the box body 1, and is slidably connected with the elevator guide rail 9. The box cover 2 is installed on the upper surface of the box body 1, and the top of the box body 1 is in contact with the elevator guide rail 9. A deflector 10 is arranged on the side surface, and one end of the deflector 10 is hinged with the box body 1, and the other end is offset a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com