LED light source strip used for modularized lamp box

A technology of LED light source and light box, applied in the direction of light source, light source fixation, lighting device components, etc., can solve the problems of hidden danger of canvas replacement, inconvenient handling and installation, and difficult maintenance, etc., to improve the display effect and facilitate handling and installation. The effect of dismantling, reducing the difficulty of handling and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

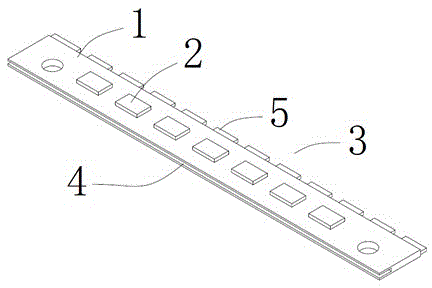

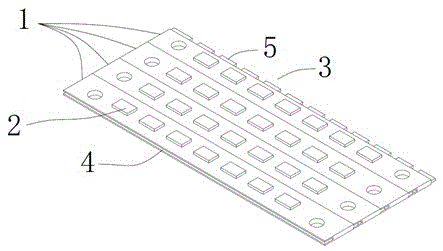

[0038] Embodiment 1: as Figure 1-3 as shown,

[0039] An LED light source bar for a modular light box, comprising a substrate 1 and several LED chips 2 arranged on the substrate 1, one side of the substrate 1 along the length direction is provided with a tenon 3, and the other side is provided with a clip Groove 4, the detachable connection between two adjacent LED light source strips is achieved through the cooperation of the tenon 3 and the groove 4.

[0040]In the above solution of this embodiment, the detachable connection between two adjacent LED light source strips is achieved through the cooperation of the tenon 3 and the slot 4 provided on each of them, so that the light source formed by the combination of each LED light source strip The assembly has good integrity, and the entire light source assembly is flat, so that each position on the light source assembly emits light evenly and improves the display effect of the light box; on the other hand, compared with the o...

Embodiment 2

[0041] Example 2, such as Figure 1-3 Shown:

[0042] As in the LED light source bar described in Embodiment 1, each tenon 3 includes several tenon segments 5 arranged at intervals, and the height of the tenon 3 is greater than the depth of the groove 4. When the tenon 3 When the tenon 3 is mated with the slot 4 , there is a gap between the end of the tenon 3 and the bottom of the slot 4 .

[0043] In the above solution of this embodiment, the tenon 3 is set as several tenon segments 5, while ensuring the reliable fit of adjacent LED light source strips, there is a gap between two adjacent LED light source strips. When working, the heat generated on the LED light source bar can be exchanged from the gap, thereby improving the heat dissipation capacity of the LED light source bar and further improving the reliability of the light box; there is a gap between the end of the tenon 3 and the bottom of the slot 4 , further improving the heat dissipation capacity of the LED light s...

Embodiment 3

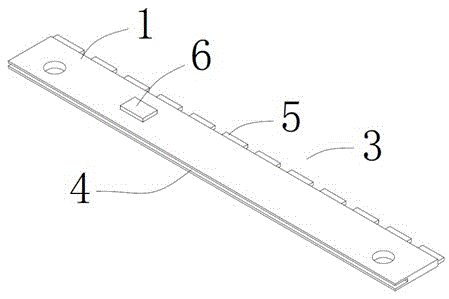

[0044] Example 3, such as Figure 1-3 Shown:

[0045] As in the LED light source bar described in Embodiment 2, the substrate 1 is provided with a power module 6 electrically connected to the LED chip 2, the power module 6 is electrically connected to an external power supply, and the power module 6 is electrically connected to the external power supply. An external module is also arranged between them, and the power modules 6 of all LED light source bars in the same light box are electrically connected to the same external module, and the external module is electrically connected to an external power supply, and the power module 6 is connected to the external power supply. There is a quick-plug conductive connection between the modules, and a quick-plug conductive connection between the external module and the external power supply.

[0046] In the above scheme of this embodiment, the substrate 1 is provided with a power module 6 electrically connected to the LED chip 2, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com