Design method of novel ozone generator jet plate

A technology of ozone generator and design method, which is applied in the direction of electrical components, semiconductor devices, climate sustainability, etc., can solve the problems of uneven oxide film, uneven air flow of air jet plate, etc., and achieve the effect of uniform air flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The technical solution of the present invention will be described in further detail below in conjunction with the accompanying drawings.

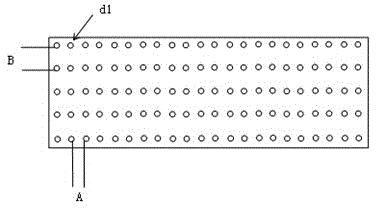

[0013] In this example, after preparing an oxide film on the surface of a silicon wafer using the traditional ozone generator air jet pore structure and the air jet air pore structure provided in the present invention, the prepared oxide film is judged by detecting the hydrophilicity of the silicon wafer. uniformity. The air holes of the traditional ozone generator jet plate adopt a side-by-side arrangement structure, and its design size is as follows: the diameter of each air hole d 1 =1mm, the distance between two adjacent air holes in the same row is A=5mm, the distance between two adjacent air holes is B=10mm, and the air holes of the ozone generator jet plate prepared by the above-mentioned structural size are prepared on the surface of the silicon wafer by using this device Oxidation film, and the hydrophilicity test. Firstly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com