Manufacturing method for meteorite sword

A technology of meteorites and swords, which is applied in the field of preparation of meteorites and swords, can solve problems such as rust, and achieve the effects of promoting molecular movement, optimizing internal uniformity, and active molecular diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

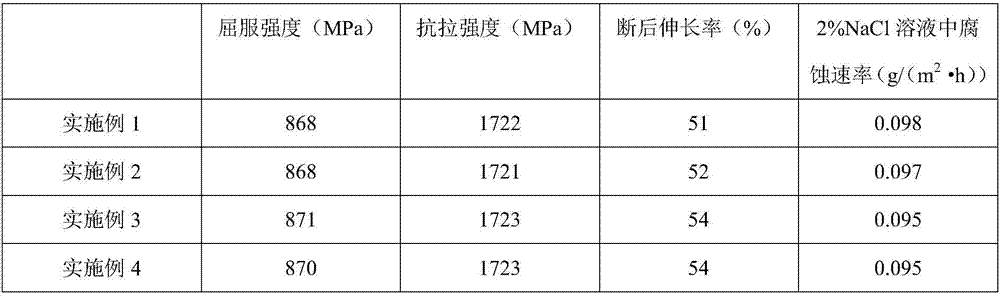

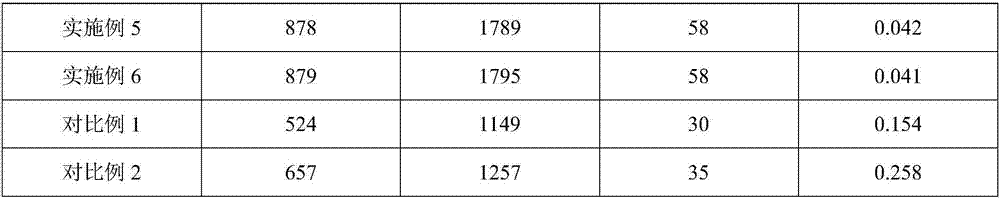

Examples

Embodiment 1

[0023] The preparation method of meteorite sword, described meteorite is iron meteorite, concrete steps are as follows:

[0024] (1) breaking the meteorite into fragments and melting them into ingots in a smelting furnace;

[0025] (2) Forging the ingot at 20MPa and 1500°C, with a forging ratio of 1;

[0026] (3) stamping the ingot into several sheets with a thickness of 0.2 mm;

[0027] (4) Randomly select the first piece from the pieces and place it in the melting furnace, heat it to 1800°C, and after the first piece is softened, put in the second piece and stick it on the surface of the first piece, The two are bonded, and then put into the third sheet, and the bonding operation is repeated until each sheet is bonded layer by layer, and the temperature is slowly raised to 2500°C at a heating rate of 2°C / min, and the plate is forged with an air hammer ;

[0028] (5) Grind the plate body into the shape of a sword, then heat-treat it, use a mixture of polyvinyl alcohol and ...

Embodiment 2

[0032] The preparation method of meteorite sword, described meteorite is iron meteorite, concrete steps are as follows:

[0033] (1) breaking the meteorite into fragments and melting them into ingots in a smelting furnace;

[0034] (2) Forging the ingot at 30MPa and 1800°C, with a forging ratio of 1.5;

[0035] (3) Stamping the ingot into several sheets with a thickness of 0.3mm;

[0036] (4) Randomly select the first piece from the pieces and place it in the melting furnace, heat it to 2000°C, and after the first piece is softened, put in the second piece and stick it on the surface of the first piece, The two are bonded, and then put into the third sheet, and the bonding operation is repeated until each sheet is bonded layer by layer, and the temperature is slowly raised to 3000°C at a heating rate of 2°C / min, and the plate is forged with an air hammer ;

[0037] (5) Grind the plate body into the shape of a sword, then heat-treat it, use a mixture of polyvinyl alcohol and...

Embodiment 3

[0041] The preparation method of meteorite sword, described meteorite is iron meteorite, concrete steps are as follows:

[0042] (1) breaking the meteorite into fragments and melting them into ingots in a smelting furnace;

[0043] (2) Forging the ingot at 20MPa and 1800°C, with a forging ratio of 1;

[0044] (3) Stamping the ingot into several sheets with a thickness of 0.3 mm;

[0045] (4) Randomly select the first piece from the pieces and place it in the melting furnace, heat it to 1800°C, and after the first piece is softened, put in the second piece and stick it on the surface of the first piece, The two are bonded, and then put into the third sheet, and the bonding operation is repeated until each sheet is bonded layer by layer, and the temperature is slowly raised to 3000°C at a heating rate of 2°C / min, and the plate is forged with an air hammer ;

[0046] (5) Grind the plate body into the shape of a sword, then heat-treat it, use a mixture of polyvinyl alcohol and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com