Forming method of wall-thickness-variable composite skirt

A composite material and molding method technology, applied in the field of composite material molding, can solve the problems of poor molding quality, high demolding cost, high manufacturing cost, etc., and achieve the effects of shortening production cycle, reducing porosity, and improving molding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] A method for forming a skirt made of variable wall thickness composite material, comprising the following steps:

[0060] Step 1, respectively prepare section 1 21 and section 2 22 of the blank of component 2 2, and divide section 1 21 into two sections;

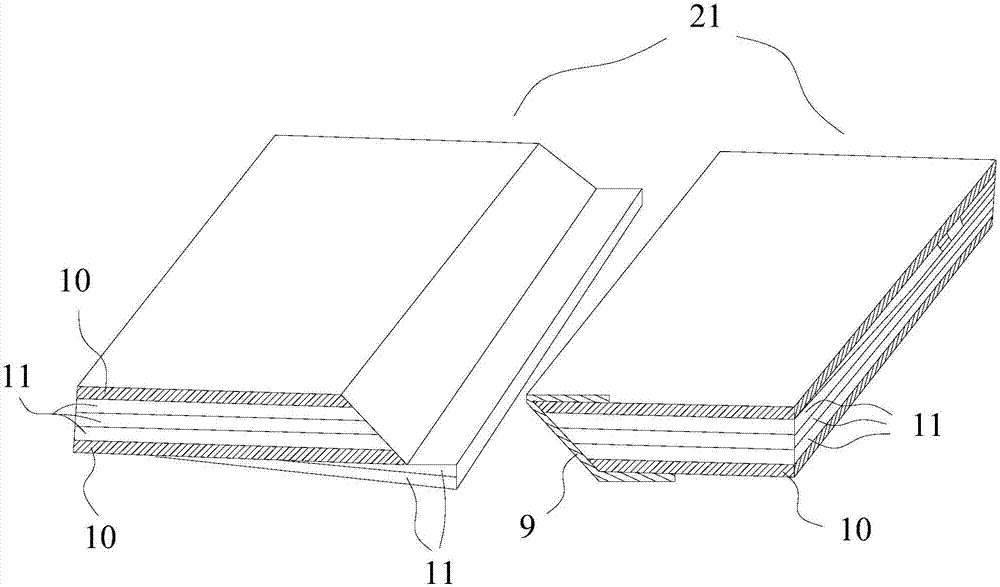

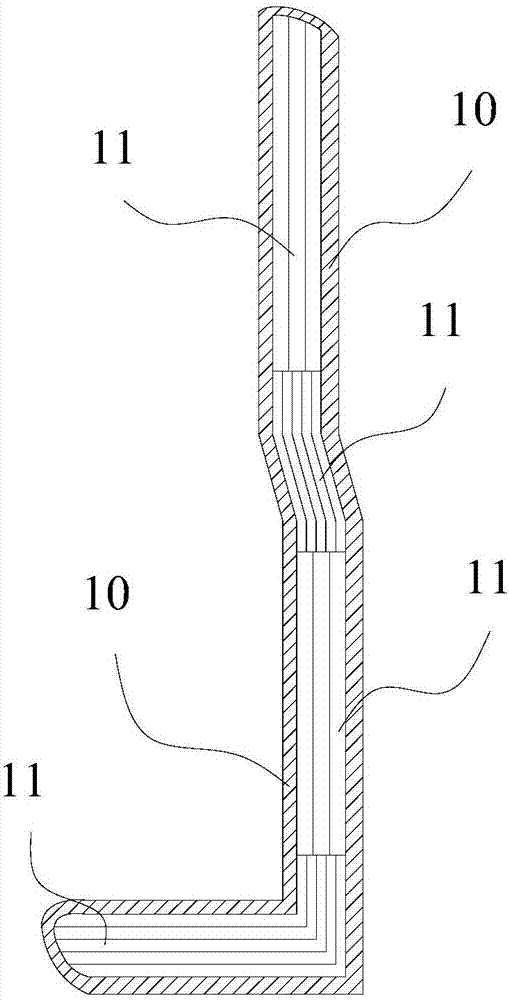

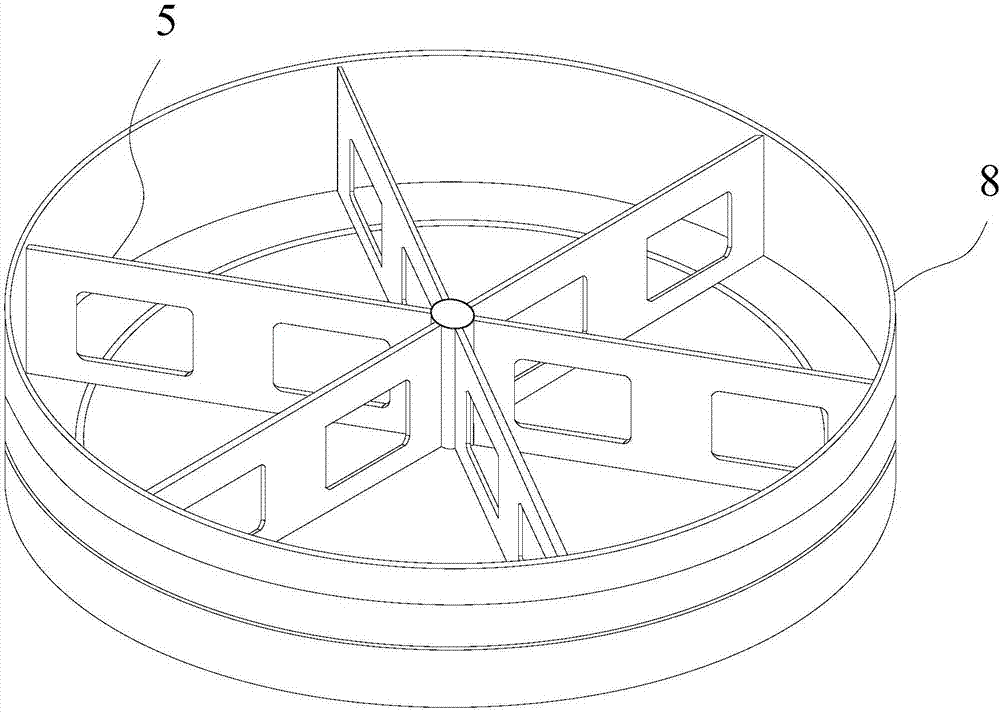

[0061] Step 2. First attach the non-porous isolation film 6 on the surface of the member three 8, attach the section one 21 to the outer surface of the member three 8, and at the junction of the two sections of the section one 21, A carbon fiber fabric prepreg 11 is laid on the side in contact with the member three 8, and a release cloth 9 is arranged between the two sections of the section one 21;

[0062] Step 3, attaching the remaining part of the outer surface of the member 3 8 to the section 2 22, and the two ends of the section 22 overlap with the two ends of the section 1 21 respectively;

[0063] Step 4, set a non-porous isolation film 6, an air felt 7 and a vacuum bag 4 on the outside of the blank of the com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com