Well completion method for standing column well enhanced geothermal system

An enhanced geothermal technology, applied in geothermal energy, geothermal energy power generation, geothermal collectors, etc., can solve the problems of high cost of dry hot rock geothermal energy development, expensive fracturing, and expensive drilling costs, etc., to reduce Geothermal mining cost, low cost, good heat transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

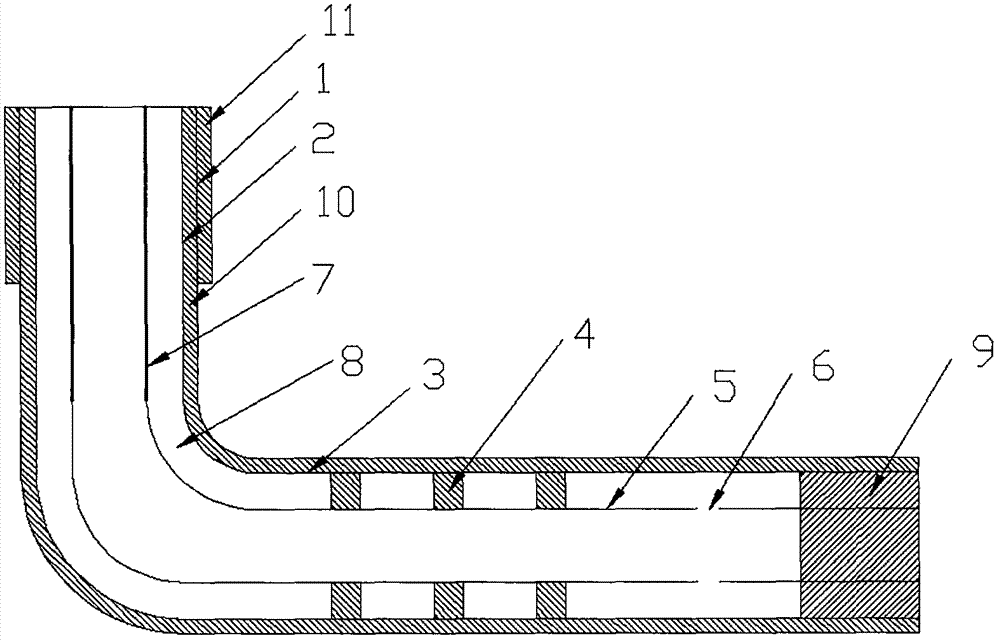

[0017] The following is attached figure 1 , describe the present invention in detail, as follows:

[0018] A single well circulation enhanced geothermal system completion method, the main surface casing 1, common technical casing 2, high temperature resistant technical casing 3, high temperature resistant centralizer 4, tubing 5, perforation holes 6, high temperature resistant coating 7. The annular space 8 formed by the technical casing and the oil pipe is composed of a cement plug 9.

[0019] The invention drills the geothermal reservoir in the form of a horizontal well under the condition that the geothermal reservoir location, orientation, depth and other parameters are determined, and the sequence is a vertical well, a deflection well and a horizontal well. Drilling at the predetermined location; the drilled well is the second horizontal well, and the horizontal well technology can fully increase the heat exchange area between the wellbore and the formation, and the hori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com