A hub-ratchet combination structure

A combined structure and ratchet technology, applied in the direction of the hub, clutch, one-way clutch, etc., can solve the problems of offsetting consumption of motion performance, elongated distance, wear of ratchet block 73 and tooth groove 611, etc., and achieves both safety and improvement The effect of certainty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be further described below with reference to the accompanying drawings and specific embodiments, so that those skilled in the art can better understand and implement the present invention, but the examples cited are not intended to limit the present invention.

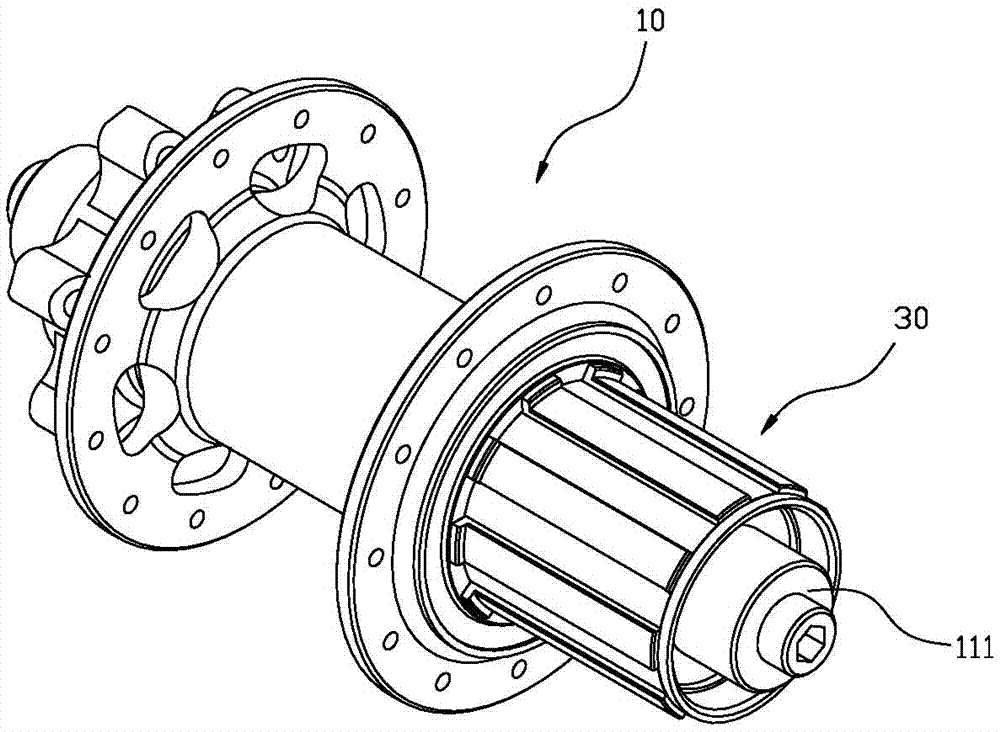

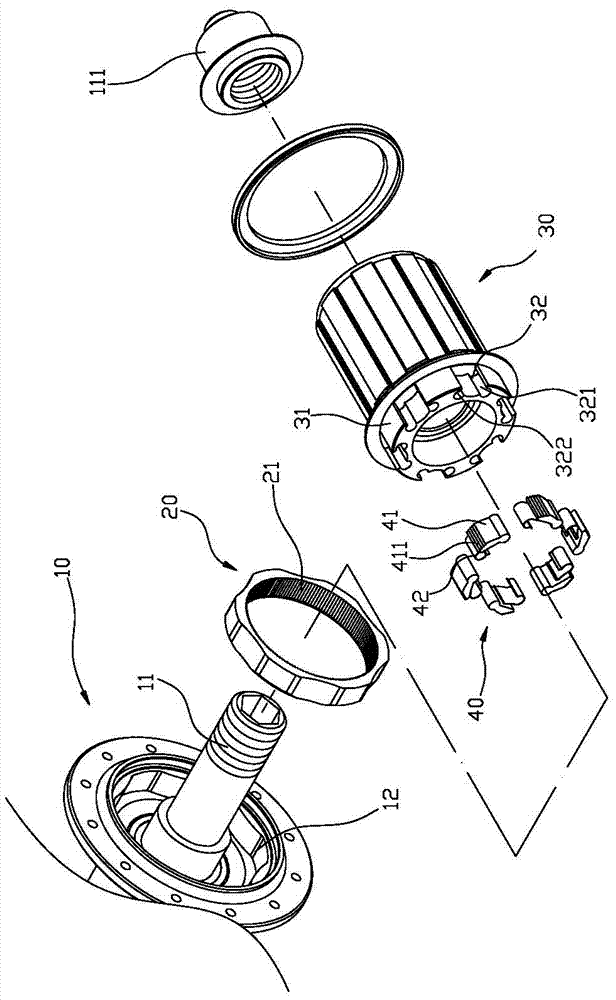

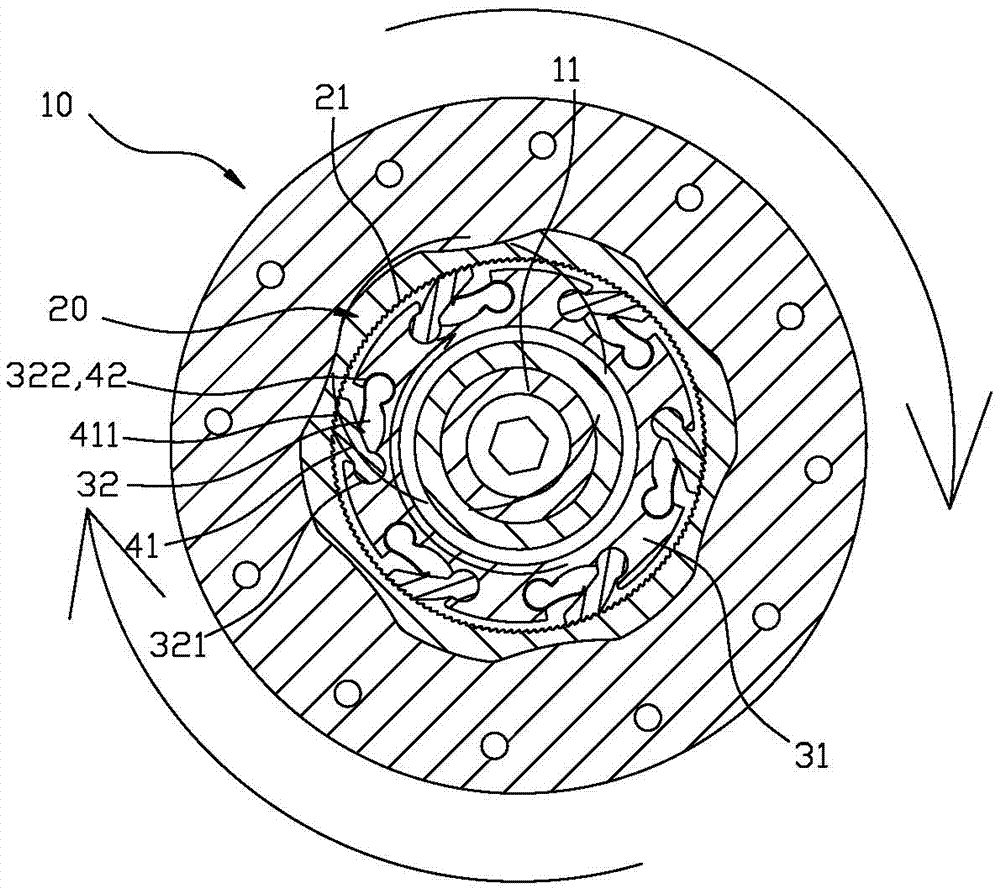

[0053] First, see figure 1 , 2 Cooperate image 3 , 4 , 5, which includes: a hub seat 10, a linkage ring 20, a sleeve seat 30 and a ratchet tooth set 40, wherein a hub seat 10 penetrates a shaft 11, and can be The shaft 11 is rotated and actuated, and a non-circular hole-shaped combined chamber 12 is provided on one side of the hub seat 10 to provide a connecting ring 20 for embedding and fixing. The outer circumference of the connecting ring 20 is non-circular, and the inner A number of linkage teeth 21 are arranged in sequence, and the number of linkage teeth 21 of the linkage ring 20 is between 145 teeth and 155 teeth. The optimal number of teeth is 150 teeth. The angle of 21 is betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com