Heat pipe with flow guide part

A technology of a flow guide and a heat pipe, applied in the field of heat pipes, can solve the problems of affecting heat exchange efficiency, low heat exchange coefficient, uneven heat exchange, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0038] In this article, if there is no special explanation, when it comes to formulas, " / " means division, and "×" and "*" mean multiplication.

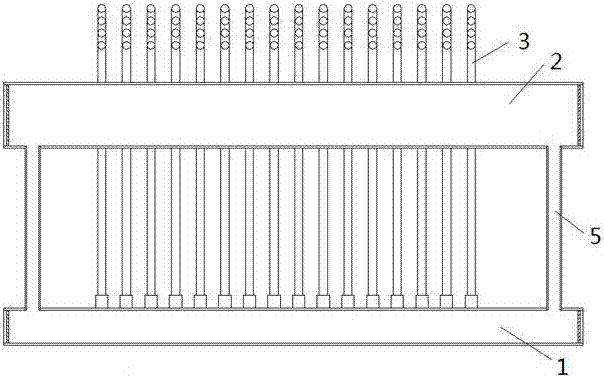

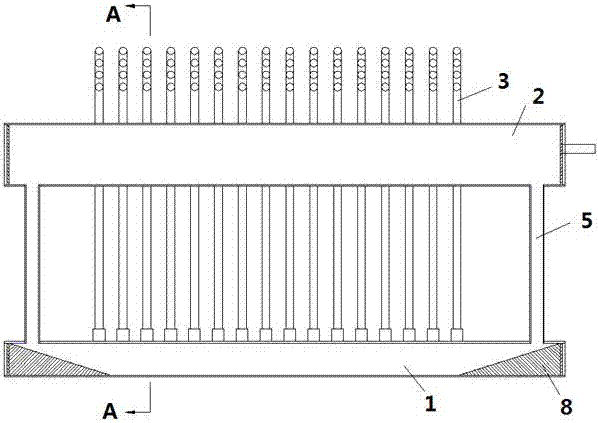

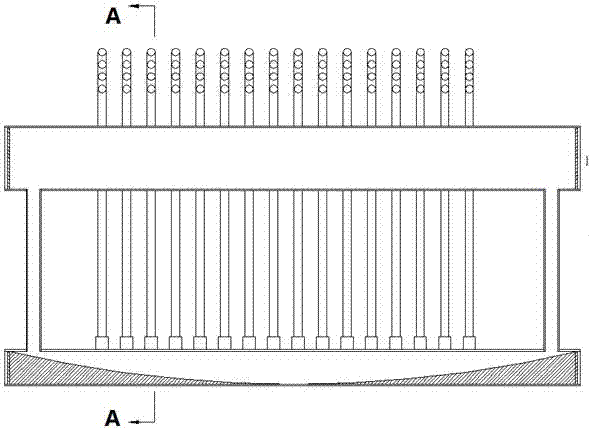

[0039] Such as figure 2 A heat pipe shown includes a lower header 1, an upper header 2, a connecting pipe 3 and a return pipe 5, the connecting pipe 2 communicates with the lower header 1 and the upper header 2, and the lower header 1 Is the evaporation end, the condensation end includes at least a part of the upper header 2 and the connecting pipe 3, the fluid absorbs heat and evaporates in the lower header 1, and after exchanging heat with at least a part of the connecting pipe 3 and the upper header 2, Condensate in the upper header 2, and the condensed fluid returns to the lower header 1 through the return pipe 5; figure 2 As shown, the lower header 1 is provided with a deflector 8 , and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com