Real-time display monitoring system of vibration motor during PCB electroplating process

A technology of vibrating motor and monitoring system, which is used in motor generator testing, measuring electricity, measuring electrical variables, etc., can solve the problems of PCB board hole breakage, real-time monitoring and display of inability to vibrate, and substandard hole rate of potion. Achieve the effect of improving the vibration amplitude and strength, and solving the board waste rate and defective rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The preferred embodiments provided by the present invention will be specifically described according to the accompanying drawings.

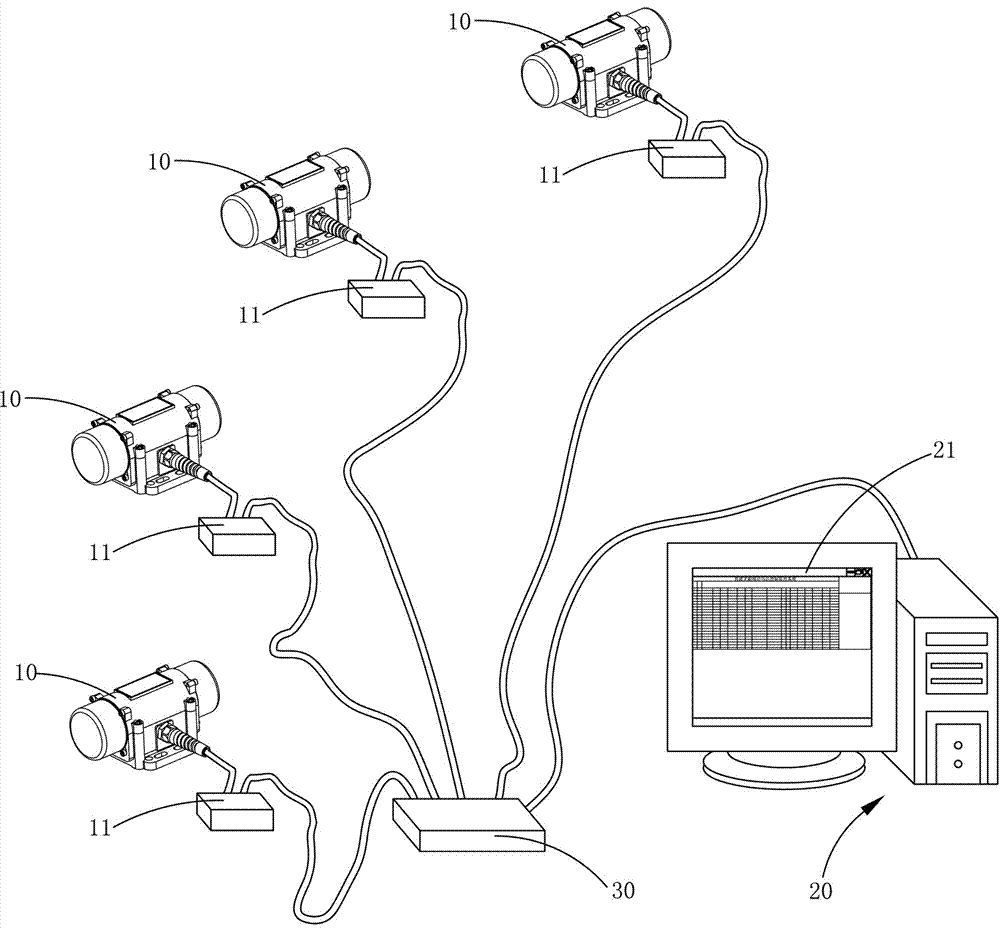

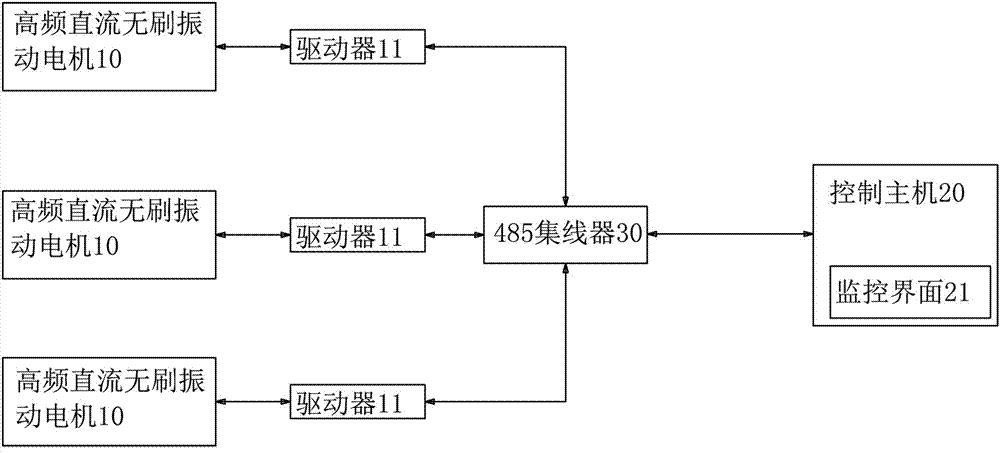

[0012] Figure 1 to Figure 2 , which is a preferred embodiment of a real-time centralized display monitoring system for a vibration motor in a PCB electroplating process provided by the present invention. Such as Figure 1 to Figure 2 As shown, the real-time centralized display monitoring system includes several electroplating equipment, and the hanger of each electroplating equipment is provided with a high-frequency DC brushless vibration motor 10, and the driver 11 of the high-frequency DC brushless vibration motor 10 is wired with the control host 20. Communication connection, the driver 11 receives the control signal sent by the control host 20, and feeds back the speed signal of the high-frequency brushless DC vibration motor 10 to the control host 20 in real time; The monitoring interface 21 of the rotating speed of the vibrating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com