A method for detecting the stability of chain pecvd coating process

A detection method and stability technology, which is applied in the field of detection of the stability of the chain PECVD coating process, can solve the problems of long time for detecting battery electrical parameters, increased production cost, and poor coating effect, so as to prevent the test results from being inconsistent. Accurate, cost-saving, improved accuracy and reliability effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

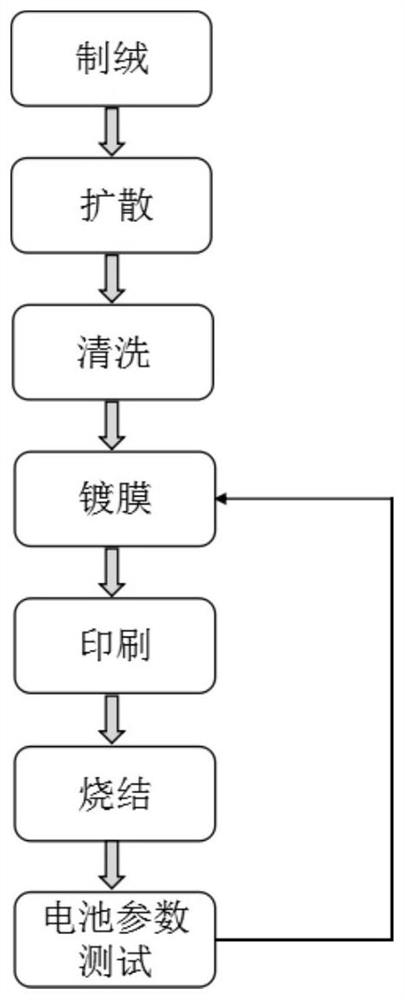

[0071] The present embodiment provides a method for detecting the stability of a chain PECVD coating process, comprising the following steps:

[0072] S1, cashmere

[0073] Soak the silicon wafer in a mixed solution of potassium hydroxide and hydrogen peroxide at 75°C for 300s to remove the damage layer on the surface of the silicon wafer introduced by cutting, and then put the above-mentioned surface-treated silicon wafer into an aqueous solution of potassium hydroxide After soaking for 600 s, the silicon wafer is etched to generate a random pyramid structure, that is, the textured silicon wafer is obtained.

[0074] Among them, the mixed solution of potassium hydroxide and hydrogen peroxide is composed of 3wt% KOH solution, 3wt% H 2 O 2 The solution is mixed with deionized water at a volume ratio of 1:9:100; the aqueous potassium hydroxide solution is obtained by mixing a 3wt% KOH solution with deionized water at a volume ratio of 3:50.

[0075] S2. Diffusion

[0076] Pu...

Embodiment 2

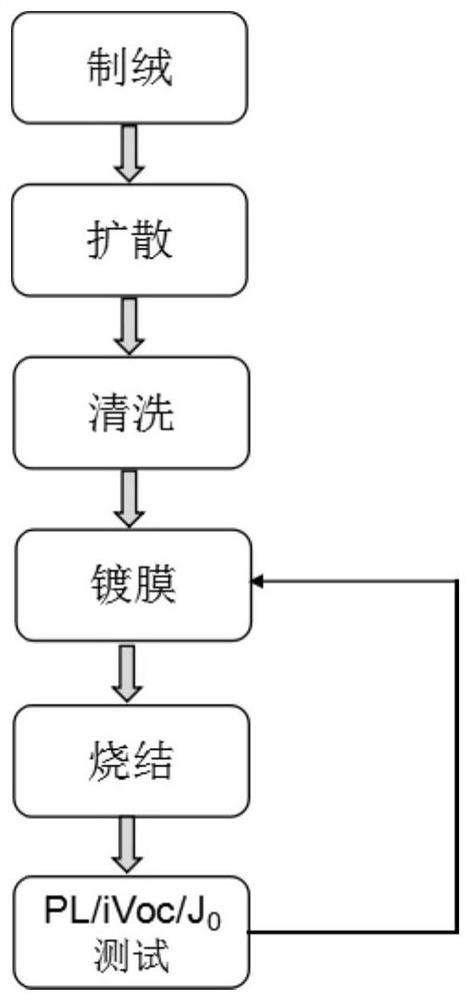

[0092] This embodiment provides a method for detecting the stability of a chain PECVD coating process. This embodiment is similar to Embodiment 1, with the only difference being:

[0093] 1) During sintering, the coated silicon wafers completed in the 30th and 98th hours of a coating cycle in S4 are selected.

[0094] 2) During the test, the semi-finished products obtained by S5 are subjected to PL and J respectively. 0 The test conditions were the same as those in Example 1.

[0095] The specific test results are shown in Table 2:

[0096] Table 2 Test results

[0097]

[0098] Note: D 2 The light-induced decay rate measured for 98h and 30h.

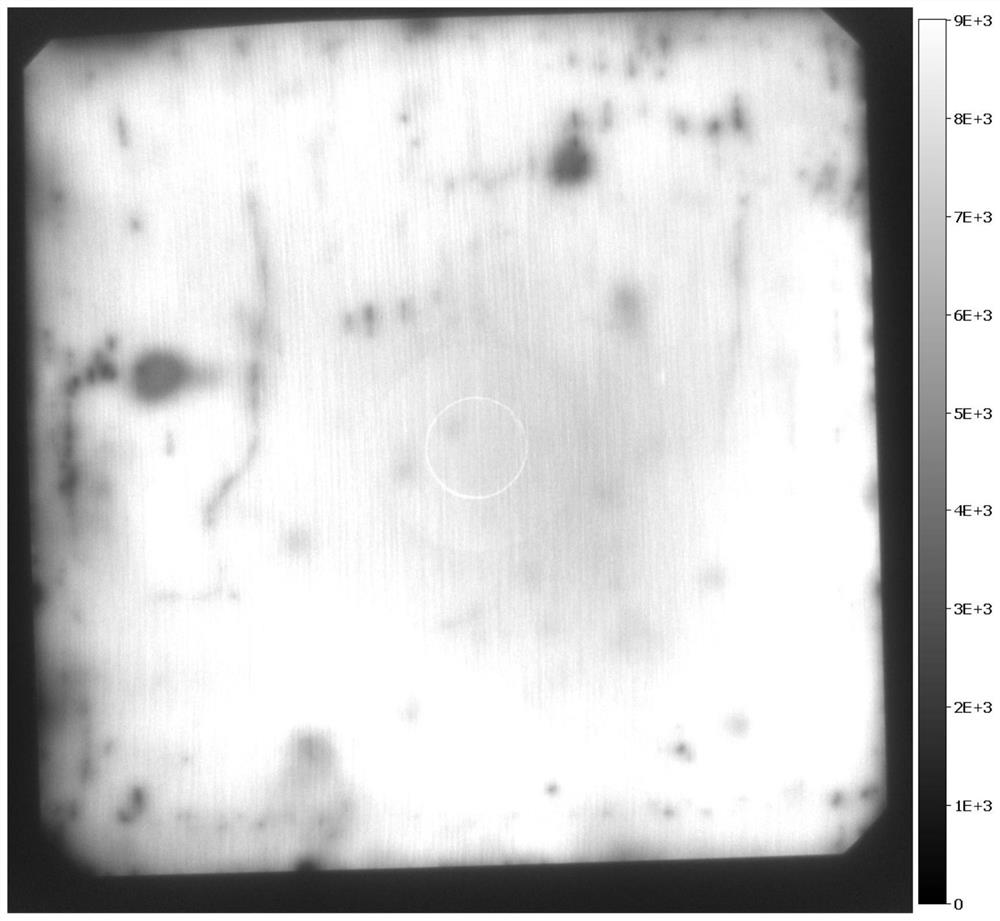

[0099] It can be seen from the data in the above table that when the equipment runs for 98h, compared with 30h, D 2 less than 10%, J 0 The center and edge test values did not increase by more than 5fA / cm relative to the 30h sampling sample test value 2 , Combined with the test results of uniform brightness in the PL picture,...

Embodiment 3

[0101] This embodiment provides a method for detecting the stability of a chain PECVD coating process. This embodiment is similar to Embodiment 1, with the only difference being:

[0102] 1) During sintering, the coated silicon wafers completed in the 30th, 90th, and 120h of a coating cycle in S4 are selected.

[0103] 2) During the test, the semi-finished product obtained by S5 was tested for PL and iVoc respectively, and the test conditions were the same as those in Example 1.

[0104] The specific test results are shown in Table 3:

[0105] Table 3 Test results

[0106]

[0107]

[0108] Note: D 2 is the light-induced decay rate measured at 90h and 30h, and D3 is the light-induced decay rate measured at 120h and 30h.

[0109] From the data in the above table, it can be seen that the sampling test is carried out at 90h, D 2 If it is less than 10%, the corresponding value of the iVoc test data center and edge does not decrease by more than 10mV compared with the tes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com