A kind of anti-glare cover plate and its manufacturing method

A manufacturing method and cover technology, which are applied in optics, optical components, nonlinear optics, etc., can solve problems such as changes in image quality and content, loss of information, etc., and achieve the effects of reducing flashing phenomena and enhancing outdoor readability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Please refer to Figure 7 , Figure 7 It is a top view of the overall structure of an anti-glare cover plate of this embodiment. An anti-glare cover plate of the present invention is used to cover a liquid crystal display panel, from Figure 7 It can be seen that it includes a transparent cover body 10, and a plurality of anti-glare units 20 are provided on the side of the cover body 10 facing away from the liquid crystal display panel.

[0039] The plurality of anti-flash units 20 are arranged in an array, and when the cover body 10 is bonded to the liquid crystal display panel, the plurality of anti-flash units 20 and the plurality of sub-pixel units of the liquid crystal display panel In one-to-one correspondence, the area of each anti-flash unit 20 is the same as the area of a corresponding sub-pixel unit.

[0040] Wherein, each of the anti-flash units 20 is provided with a plurality of light-transmitting microstructures 30, and the plurality of microstructur...

Embodiment 2

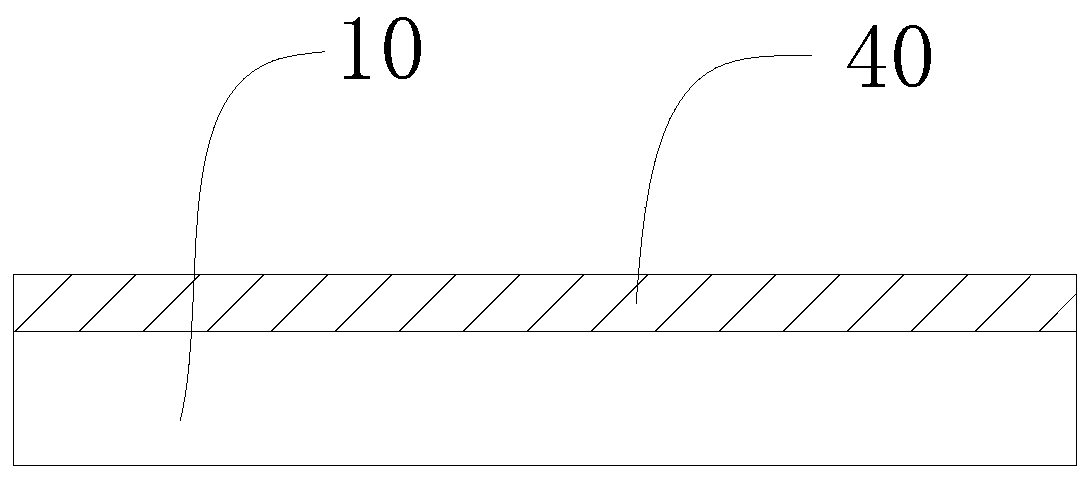

[0049] Please refer to Figure 1 to Figure 6 , figure 1 It is a schematic diagram of coating a transparent organic material layer 40 on a glass substrate in the implementation steps of an anti-glare cover plate manufacturing method according to an embodiment of the present invention;

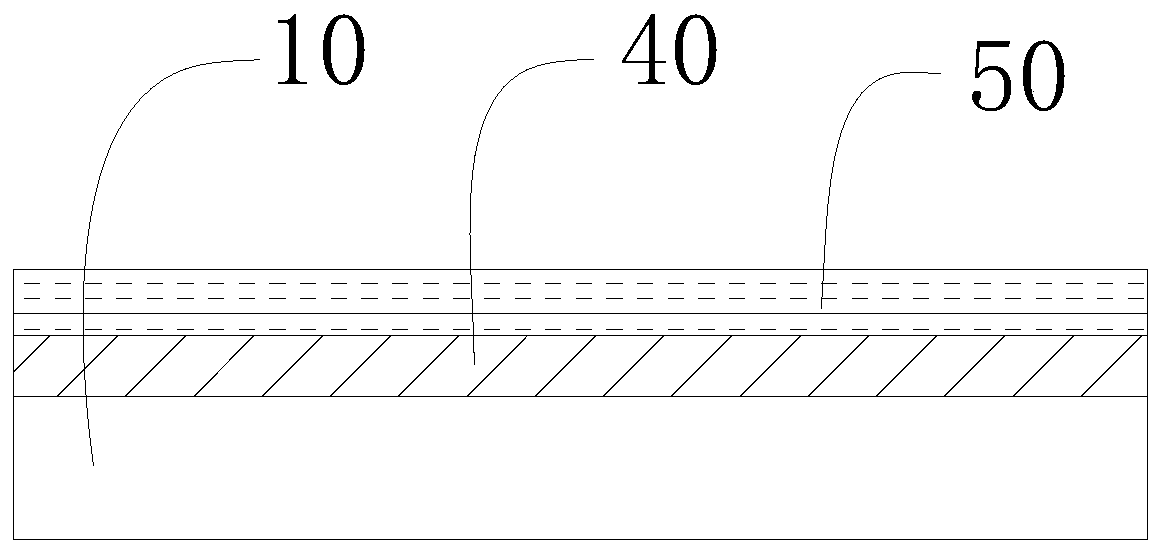

[0050] figure 2 It is a schematic diagram of coating a photoresist layer 50 on the transparent organic material layer 40 in the implementation steps of a method for manufacturing an anti-glare cover plate according to an embodiment of the present invention;

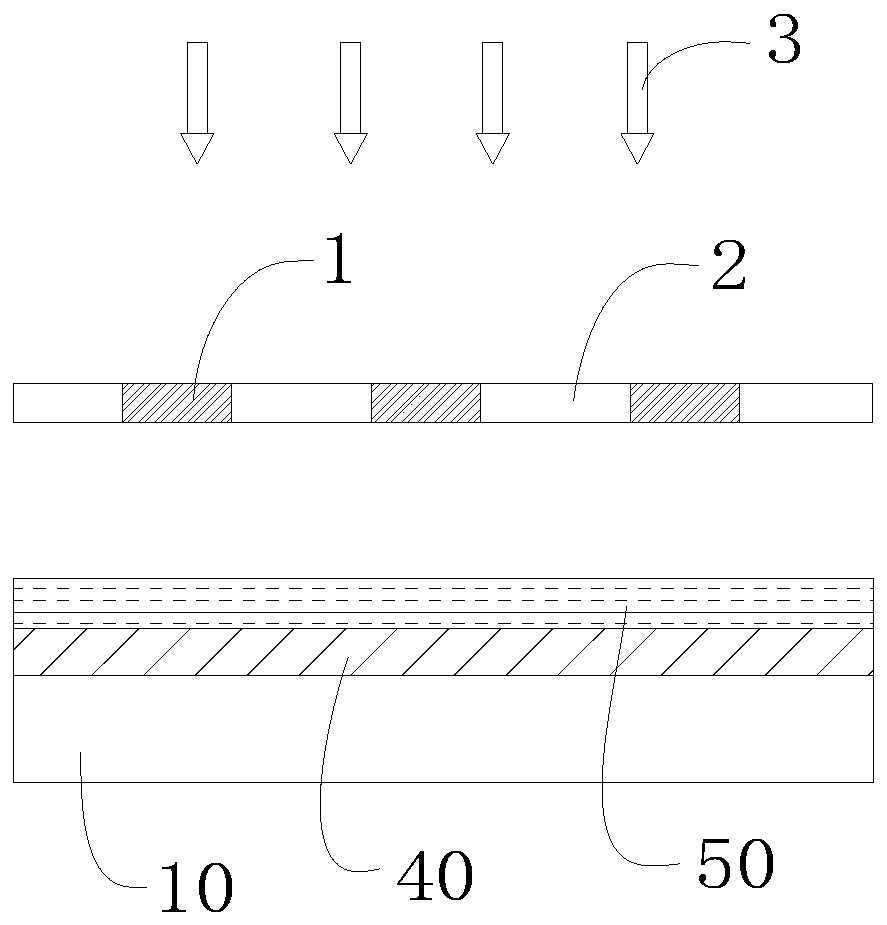

[0051] image 3 It is a schematic diagram of irradiating ultraviolet light 3 on the set photomask in the implementation steps of a method for manufacturing an anti-glare cover plate according to an embodiment of the present invention;

[0052] Figure 4 It is a schematic diagram of the photoresist layer 50 forming the shapes of the multiple microstructures 30 on the multiple anti-glare units 20 during the implementation steps of the me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com