Stator installation structure for mid-drive motor of moped

A technology of driving motor and mounting structure, which is applied in the direction of connection with control/driving circuit, structural connection, magnetic circuit shape/style/structure, etc., can solve the problems of poor heat dissipation effect of stator, small heat dissipation area of stator, and inability to provide cadence. , to achieve the effect of good heat dissipation and large heat dissipation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to describe the technical content, structural features, and achieved effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

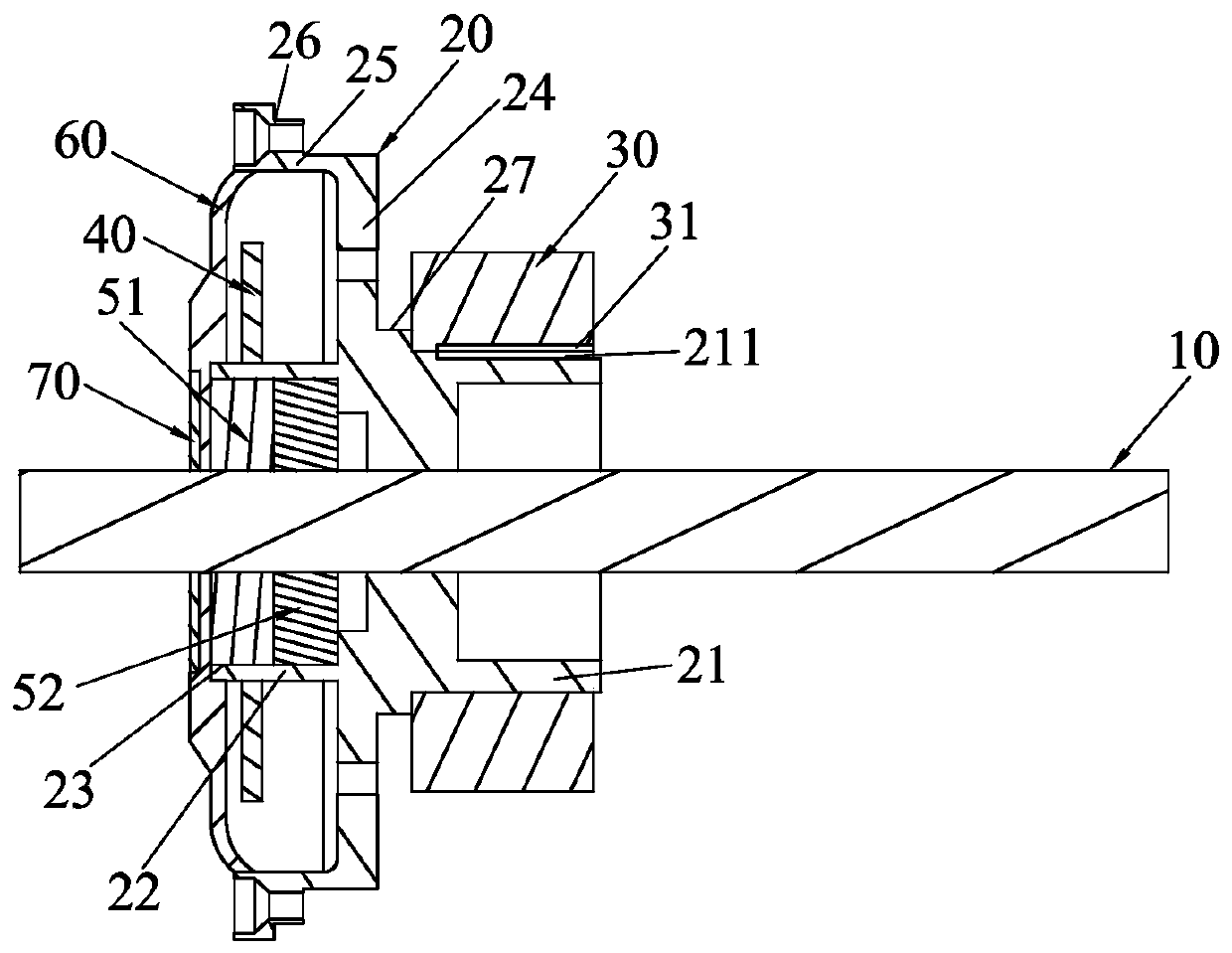

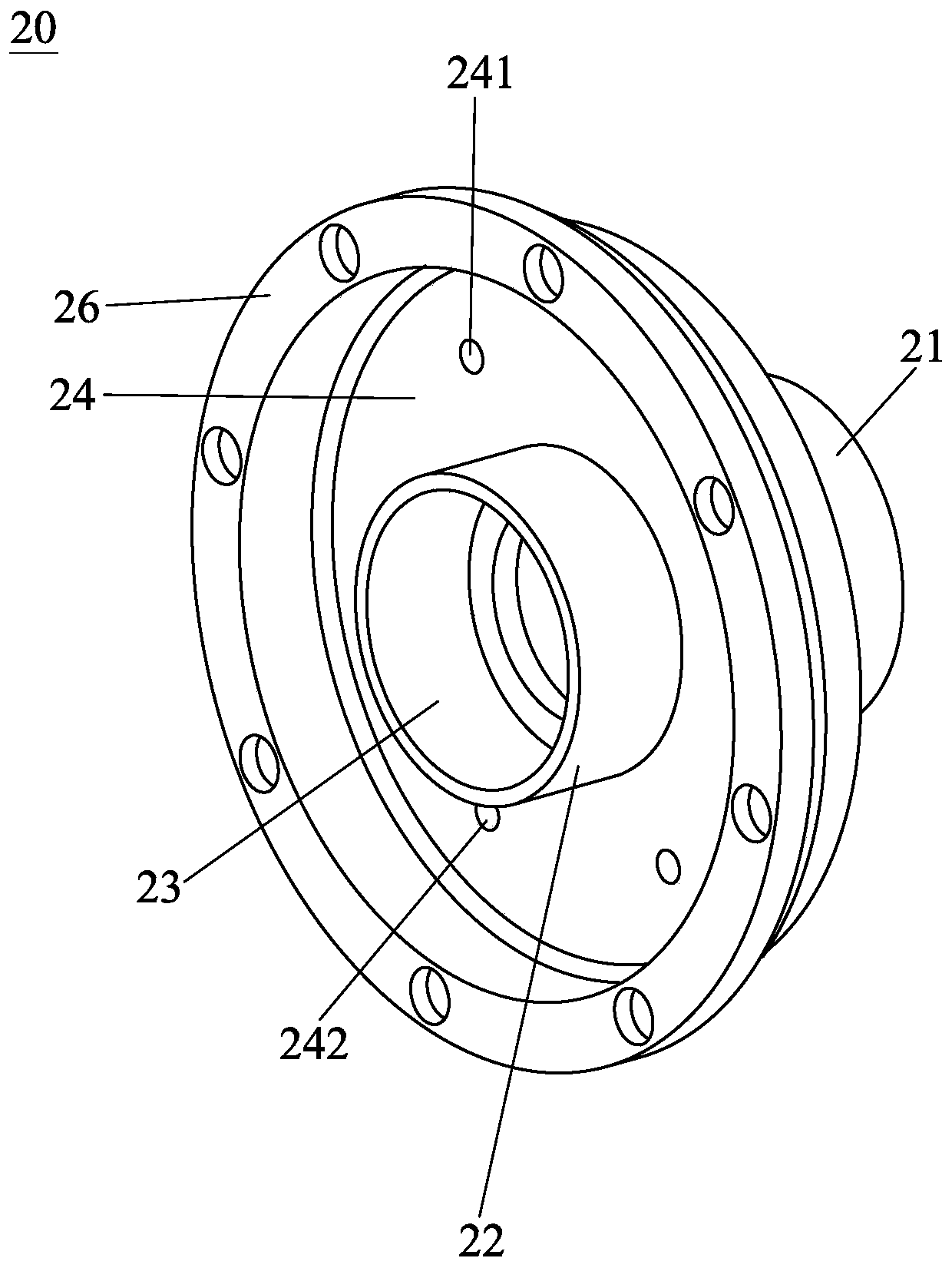

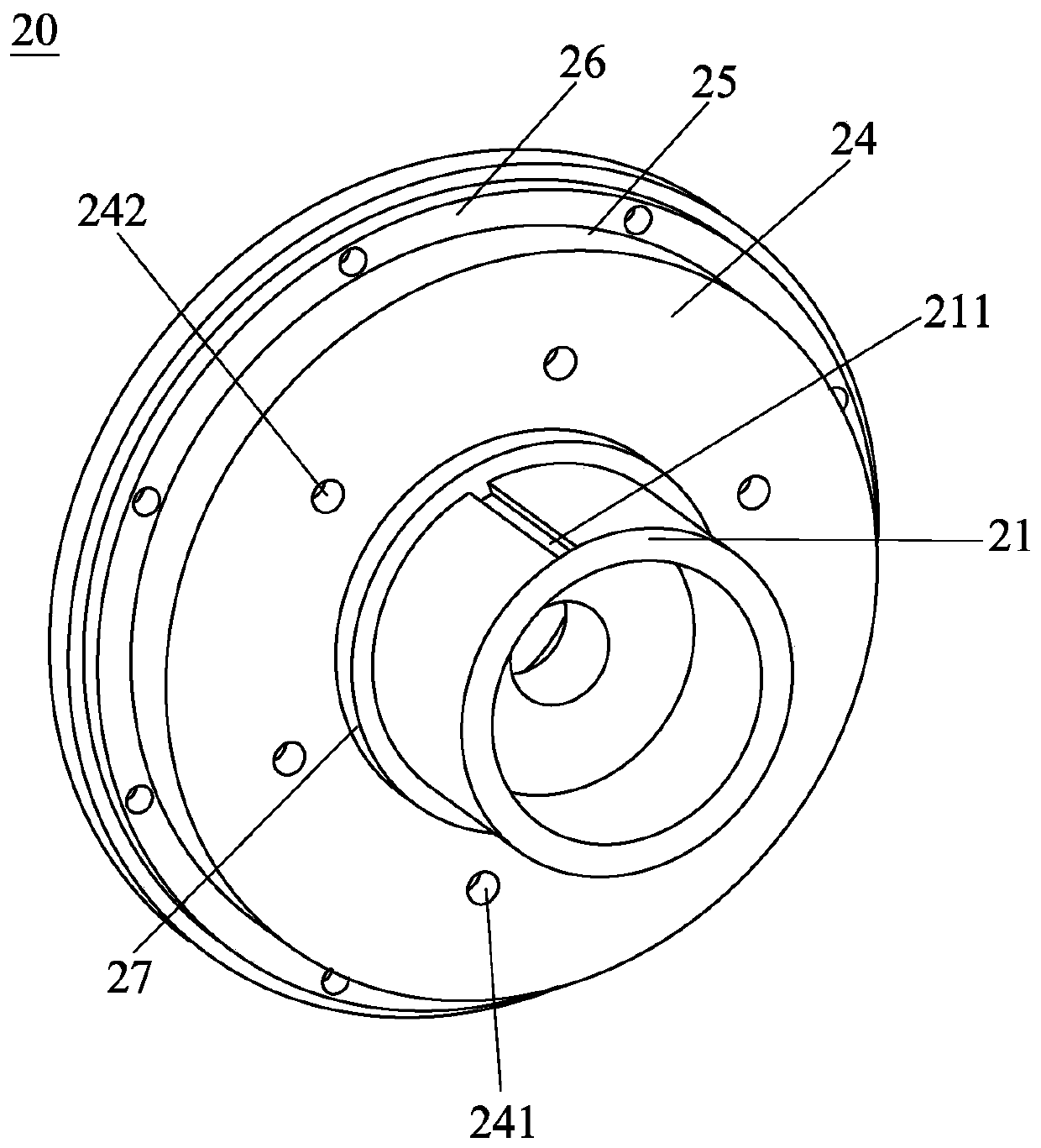

[0020] Figure 1 to Figure 4 Disclosed is a stator installation structure for a mid-mounted drive motor of a moped according to an embodiment of the present invention. The drive motor also includes a multifunctional center shaft 10, a housing (not shown), and an outer rotor (not shown). The stator is installed The structure includes a support frame 20 and a stator 30. The support frame 20 is axially hollow to be arranged concentrically with the multifunctional central axis 10 and positioned in the housing. The support frame 20 has a ring-shaped first installation Part 21 ; the stator 30 is installed and positioned on the first installation part 21 of the support frame 20 . Compared with the prior art, the stator installation structure for the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com