Cold-bending forming process for open type elastic limiting clamping ring

An elastic limit, cold-bending technology, applied in metal processing equipment and other directions, can solve the problems of not being able to bend in place at one time, and the bending force is large.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to further illustrate the technical means and effects of the present invention, a detailed description will be given below in conjunction with preferred embodiments of the present invention and accompanying drawings.

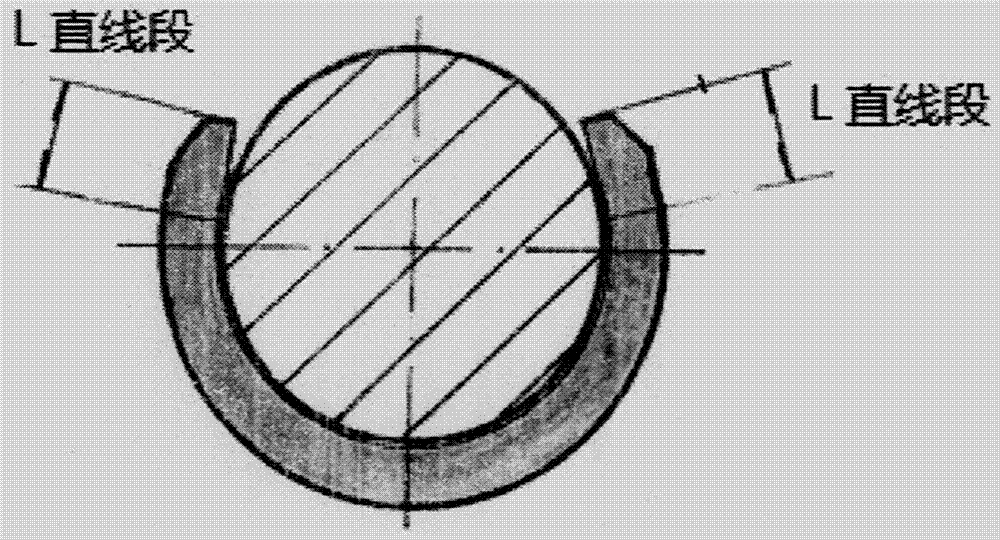

[0019] see Figure 4 , a cold-bending forming process of an open-type elastic limit snap ring, the forming process is as follows:

[0020] Step 1. Select qualified plates and use the mold to blank the material vertically to the fiber direction;

[0021] Step 2. Grinding and deburring the dropped blank;

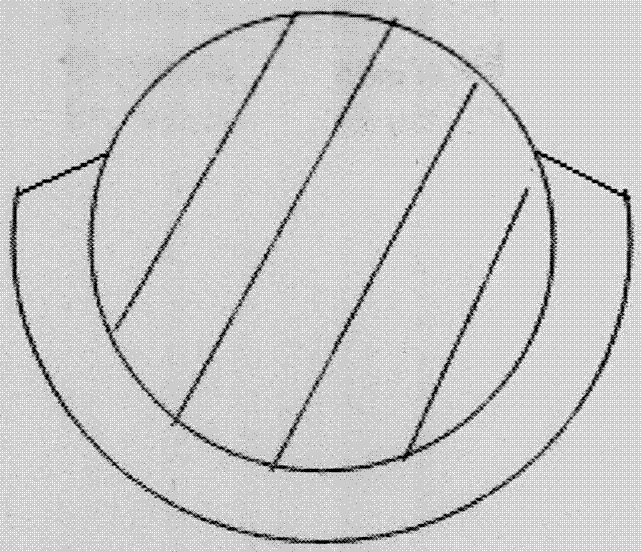

[0022] Step 3, pre-bending the blank along the direction perpendicular to the fibers of the sheet, so that the radians at both ends of the blank reach the diameter of the elastic limit snap ring (such as image 3 );

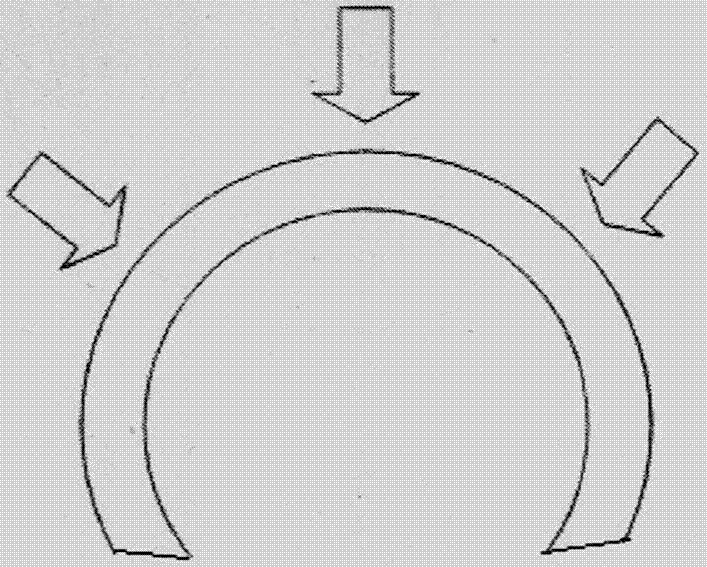

[0023] Step 4, further bending the middle part of the entire pre-bent semi-finished product, so that the entire snap ring reaches the diameter of the finished product.

[0024] Furthermore, the open-type elastic limit snap ring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com