Automatic production equipment for hot water bag and method for producing hot water bag

A technology for production equipment and hot water bags, which is applied in the field of production equipment for hot water bags, and can solve the problems of undisclosed equipment, difficult film removal, and low production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

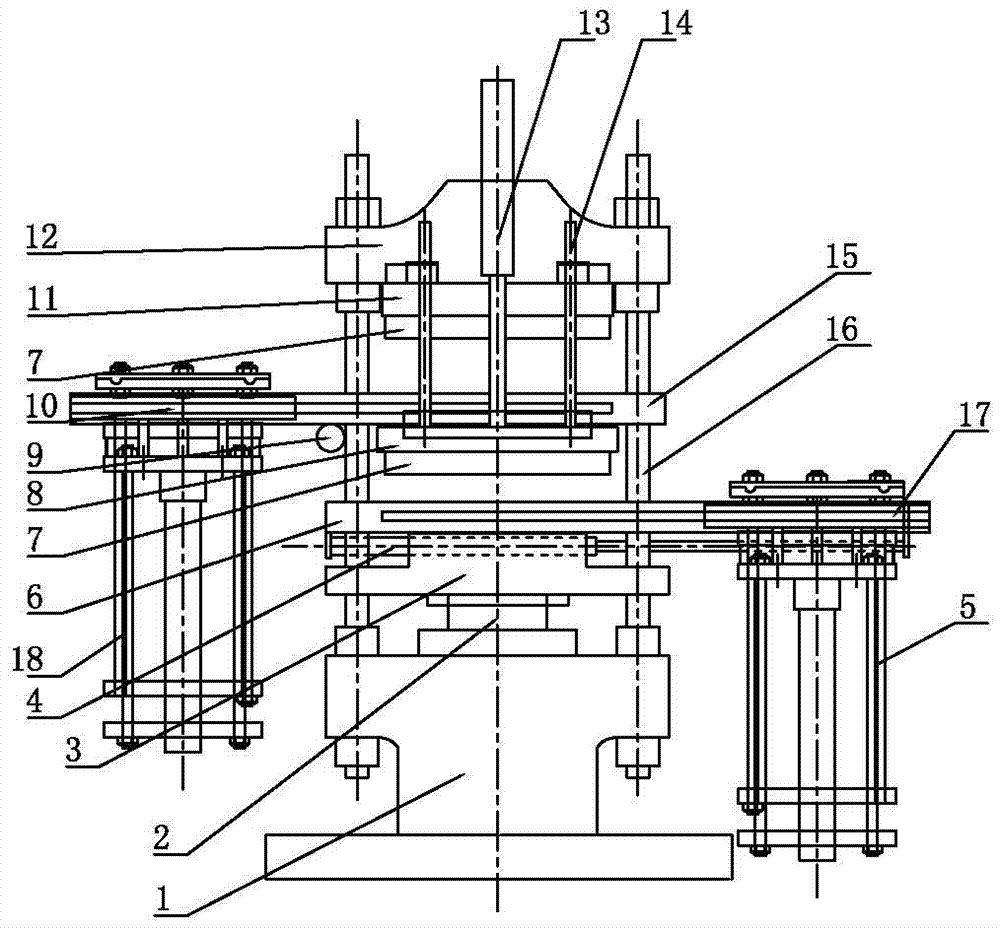

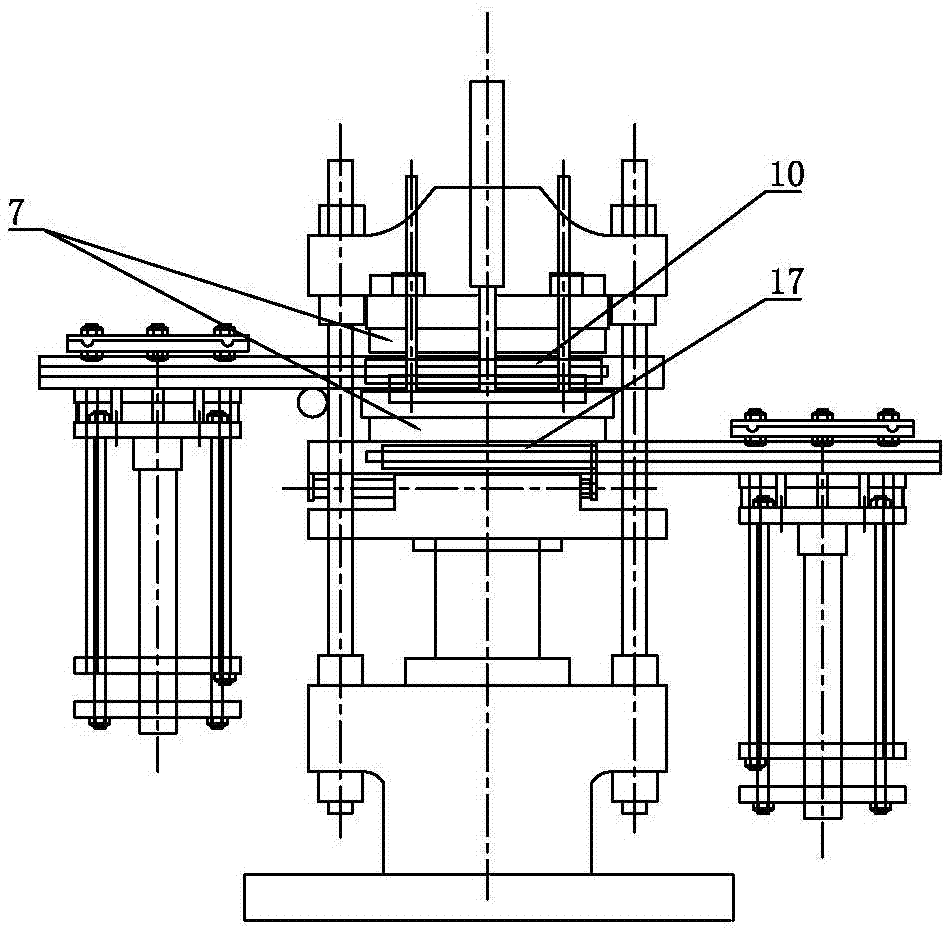

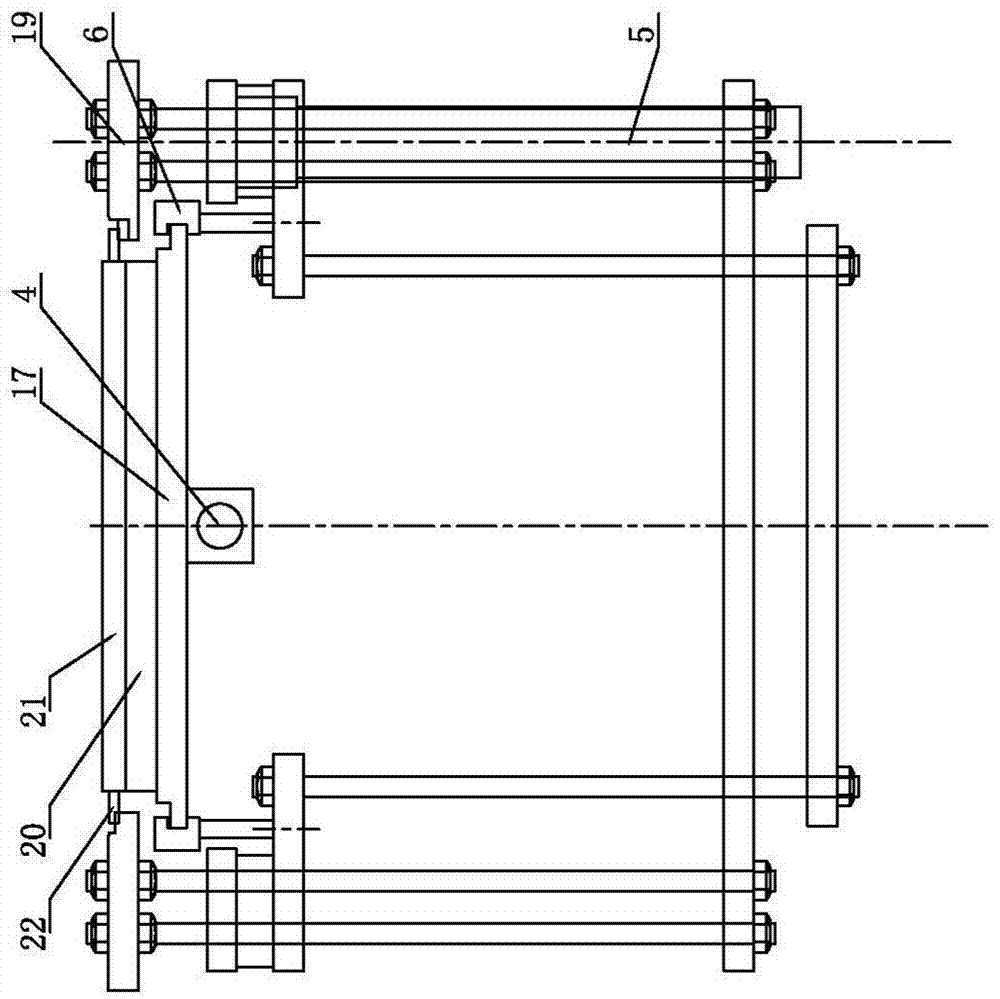

[0031] Such as Figure 1-6 As shown, it is an automatic production equipment for a hot water bag, including a machine base 1, the four corners of the machine base 1 are erected with guide posts 16, the upper ends of the guide posts 16 are fixedly installed with an upper support frame 12, and the center of the machine base 1 is vertically provided with a clamping mold Oil cylinder 2, the upper end of the piston rod of the clamping oil cylinder 2 is provided with a main slider 3, and the upper side of the main slider 3 is provided with a translation guide rail 16, and a translation guide rail 1 6 is provided with a first lower mold base 17 that can translate, the machine base 1. Corresponding to the translation guide rail 16, there is a mold core lifting support 5, through which the mold core 21 moved to the corresponding position can be pushed upwards to the lower mold 20; corresponding to the first lower mold base 17, there is a The first upper mold base 8, the first upper mol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com