Intelligent spraying dedusting system provided with funnel and used for loading and unloading machine

A technology of machine intelligence and dust removal system, applied in loading/unloading, conveyors, combined devices, etc., can solve problems such as dust pollution, and achieve the effect of reducing dust and increasing air humidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

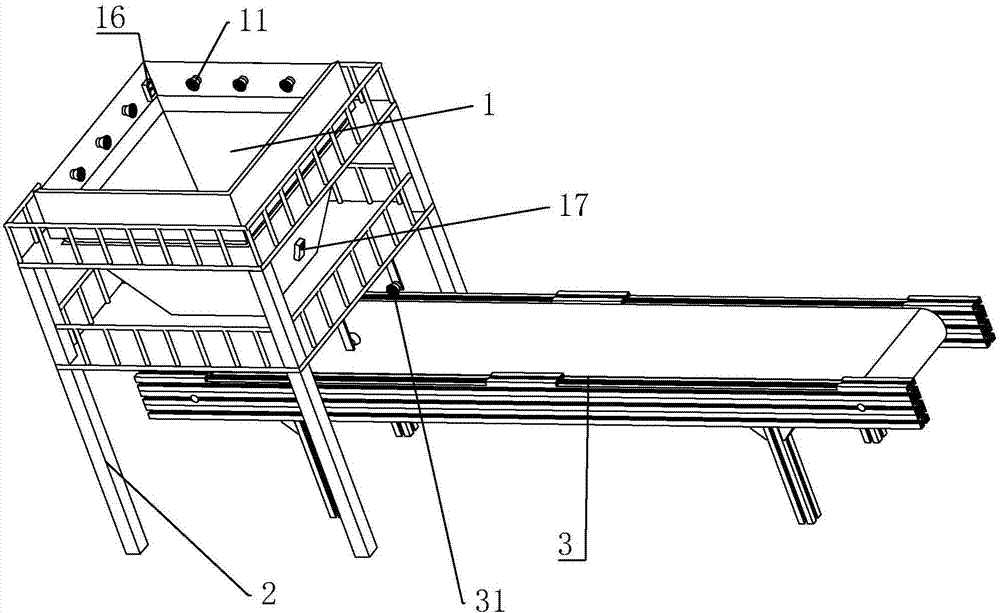

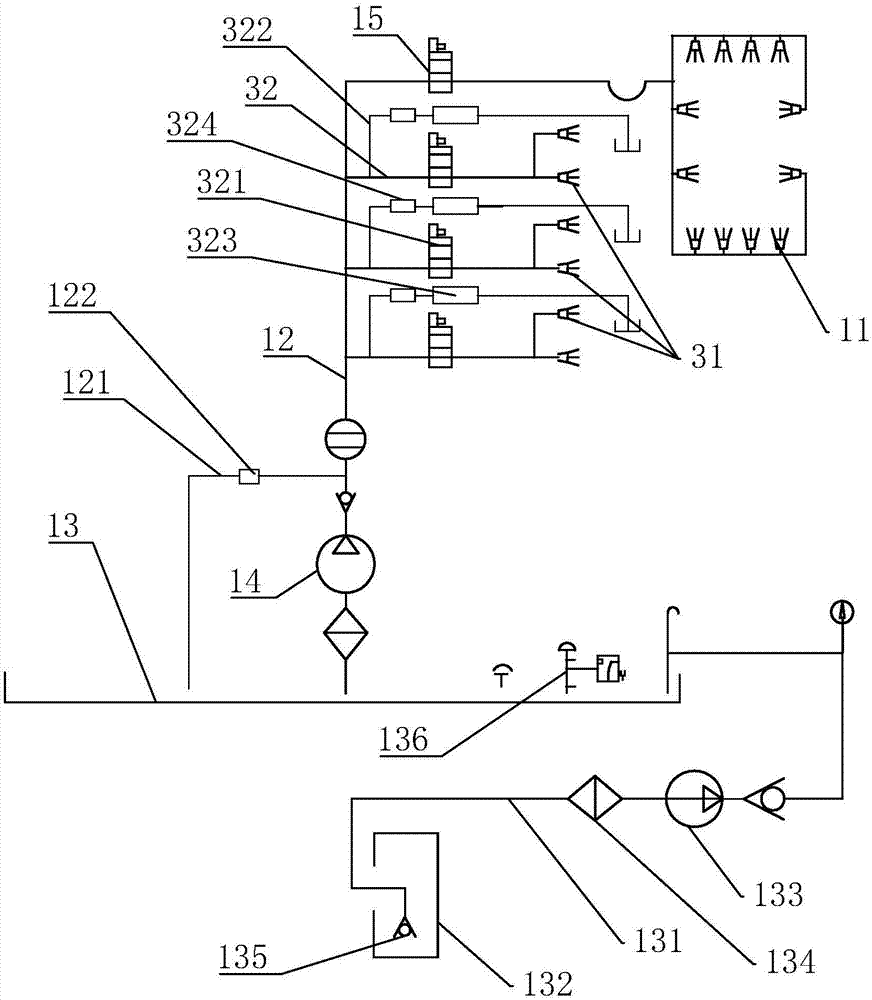

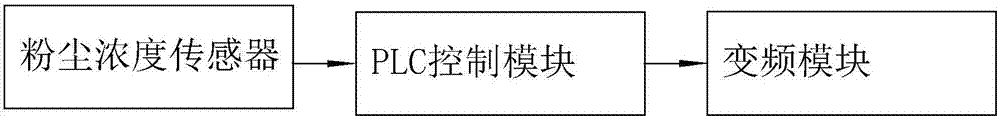

[0032] Embodiment 1: A kind of intelligent spray dust removal system of loading and unloading machine with bucket, such as figure 1 and figure 2 , including a funnel 1 and a bracket 2 that makes the inlet of the funnel 1 upward and the outlet downward. The lower end of the funnel 1 is provided with a conveying device. The conveying device can be a belt conveyor 3 or the compartment of a truck. At this time, dust will be generated above the funnel 1. At this time, the support 2 is provided with some spray nozzles-11 on the periphery of the inlet of the funnel 1. The nozzle-11 is connected with the main pipeline 12 communicated with the water tank 13. A multistage pump 14 and a solenoid valve 15 are arranged between the water tanks 13, and the solenoid valve 15 is arranged close to the nozzle 11. Spray out in a chemical way, increase the air humidity above the funnel 1, so that the water mist covers the top of the funnel 1 evenly, and after the raised dust particles collide wi...

Embodiment 2

[0041] Embodiment 2: An intelligent spray dust removal system for a loading and unloading machine with buckets, the difference from Embodiment 1 is that, as Figure 4 and Figure 5 After the funnel 1 has been used for a period of time, more dirt has accumulated on the funnel 1 and the support 2, so a cleaning pipe 21 is provided at the upper end of the support 2, and the cleaning pipe 21 communicates with the main pipe 12. The cleaning pipe 21 is provided with an electromagnetic Valve four 211, the bracket 2 is provided with a material guide plate 22 extending to the periphery of the funnel 1 inlet, the material guide plate 22 is inclined downward from the bracket 2 to the funnel 1 inlet, so that the mixture of water and dirt in the cleaning pipe 21 moves along the Flow into the funnel 1 by the flow deflector and then be discharged, and the flow deflector is beneficial for the goods to enter the funnel 1.

[0042] Such as Figure 4 and Figure 5 , the water output of the cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com