Integrated doffing device of spinning frame

A spinning frame and collective technology is applied in the field of improvement of the structure of the collective doffing device of the spinning frame, which can solve the problems of prolonging the doffing time, complicated action process, occupying space, etc. The effect of high motion accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific content of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

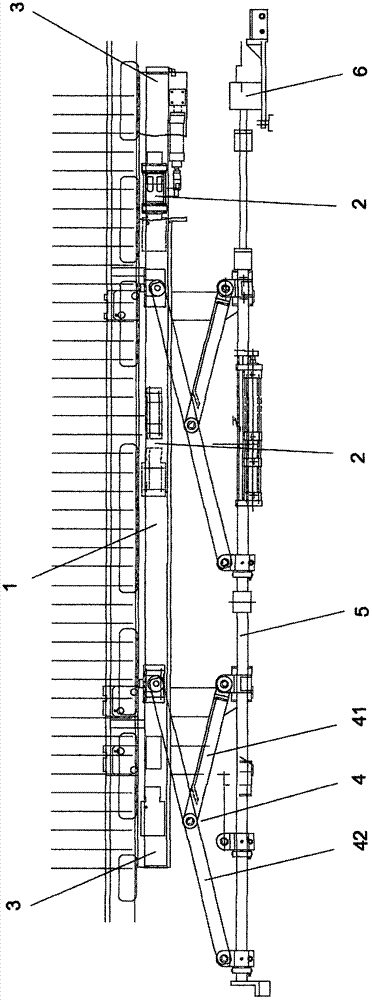

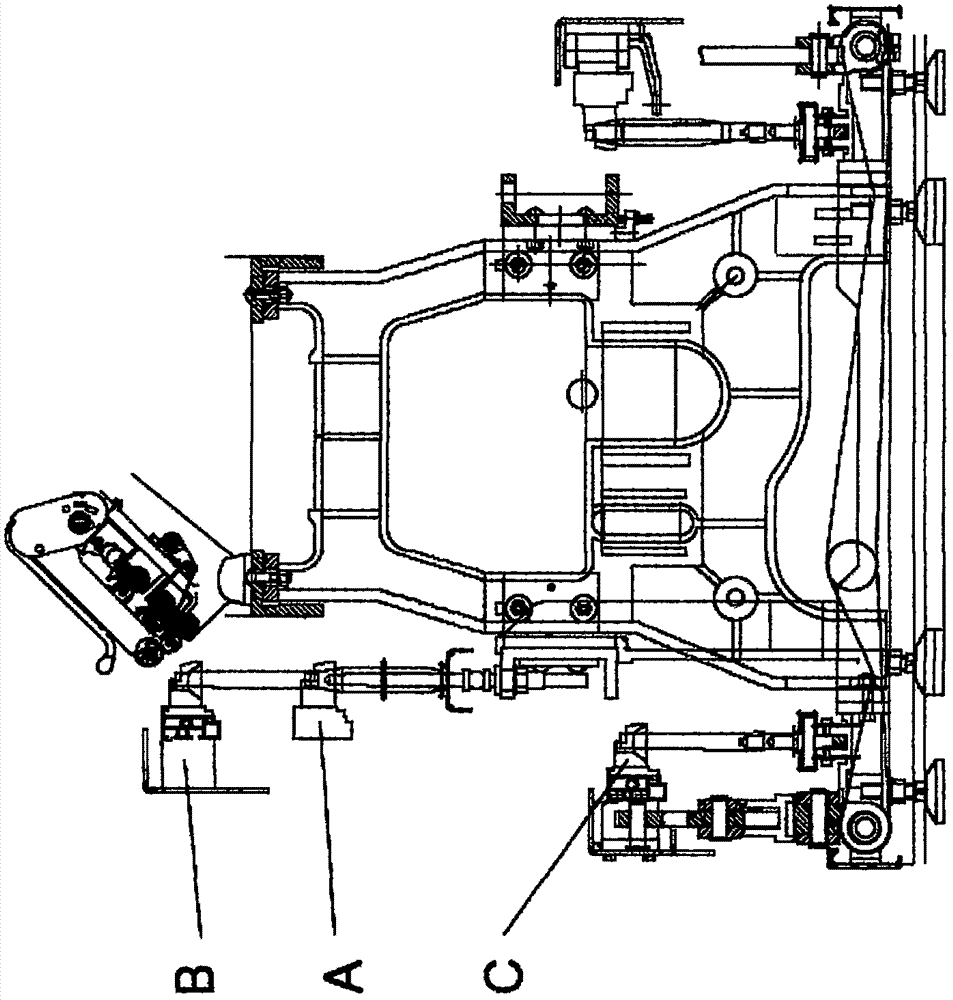

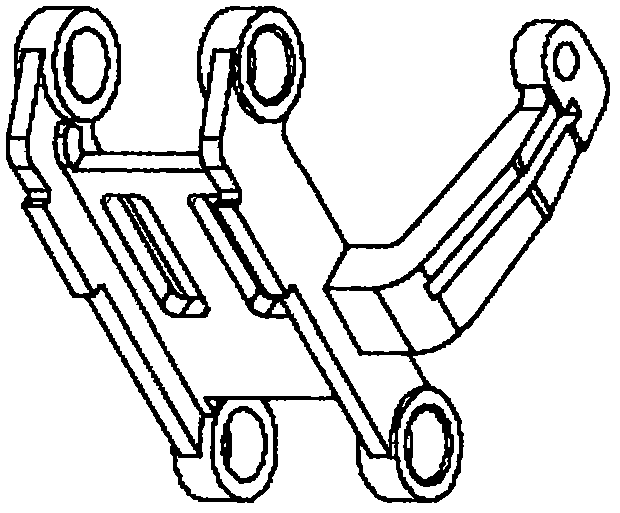

[0015] Such as figure 1 As shown, a spinning frame collective doffing device includes a yarn holder beam 1, a rotating wall 2, a holding beam 3, a herringbone lifting linkage mechanism 4, a lifting pull rod 5, and a pull rod driving device 6. The yarn holding device beam 1 extends from the head to the rear of the spinning frame, and the length of the yarn holding device beam 1 corresponds to the spindles on one side of the spinning frame. There is a hinged rotating arm 2 on the outside of the beam 1 of the yarn holding device. The rotating arm 2 consists of at least two groups, one of which is driven by a cylinder as the main arm, and the other as the slave arm. The rotating arm is used to control the yarn holding One section of the pivoting arm 2 is hinged on the yarn holder beam 1, and the other end is hinged on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com