Washing machine

A washing machine and washing tub technology, applied in the field of washing machines, can solve the problems of unfavorable water saving, large volume, and large washing water storage, and achieve the effects of avoiding residual dirt, improving utilization rate, and reducing usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

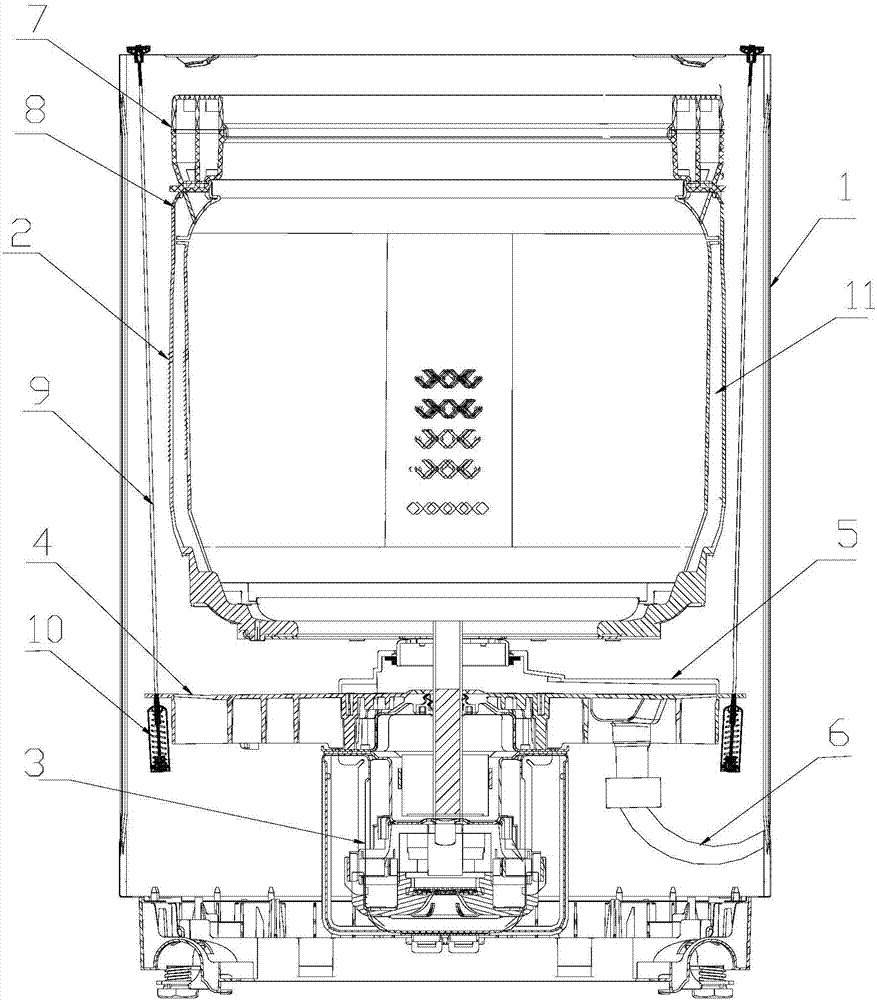

[0025] like figure 1 and figure 2 As shown, a washing machine includes a box body 1, a washing tub 2 for accommodating laundry to be washed, a power unit 3 for driving the washing tub 2 to rotate, a mounting plate 4 installed at the bottom of the washing tub 2, and a connecting mounting plate 4 Vibration-absorbing parts with box 1. The washing bucket 2 is used as a water bucket, and is rotatably arranged in the casing 1. The washing bucket 2 is located on the mounting plate 4, and can rotate relative to the mounting plate 4. The mounting plate 4 is used to support the washing bucket 2, and is installed The plate 4 is movably connected with the box body 1 through a vibration damping component. When washing or dehydrating, the washing tub 2 and the installation plate 4 will vibrate, and the vibration is transmitted to the vibration damping component and then absorbed.

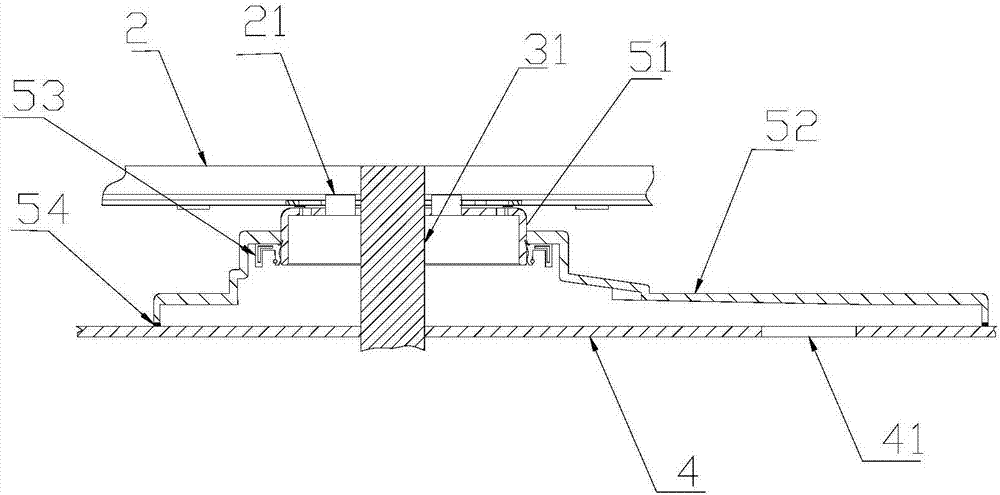

[0026] The bottom of the washing bucket 2 and the mounting plate 4 are sealed and connected by a drainage c...

Embodiment 2

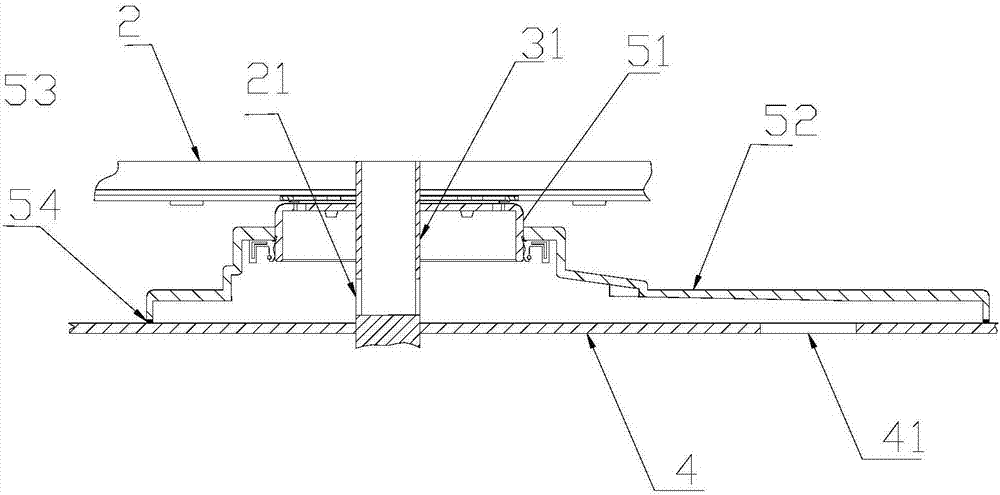

[0037] like image 3 As shown, the present embodiment further simplifies the structure of the drainage channel 5. Compared with the first embodiment, the rotating shaft 31 of the present embodiment is a hollow shaft, and its upper port communicates with the water holding chamber of the washing tub 2, and the lower port is closed, and the rotating shaft 31 is hollow. An opening is provided on the peripheral wall to communicate with the drain passage 5, and the opening directly serves as the drain 21 at the bottom of the washing tub, and there is no need to set up an additional drain at the bottom of the washing tub 2, so the structure is simpler. The washing water in the washing bucket 2 flows into the drain channel 5 through the passage inside the rotating shaft 31, and is discharged out of the washing machine through the drain pipe 6 connected with the drain port 41 on the mounting plate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com