Concrete slab and preparation method thereof

A technology for concrete slabs and slabs, which is applied to pavement, roads, and pavement details paved with prefabricated blocks. It can solve the problems of affecting construction quality, deep cutting depth, and difficulty in cutting to the end, so as to simplify the cutting process and improve the quality. , good quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

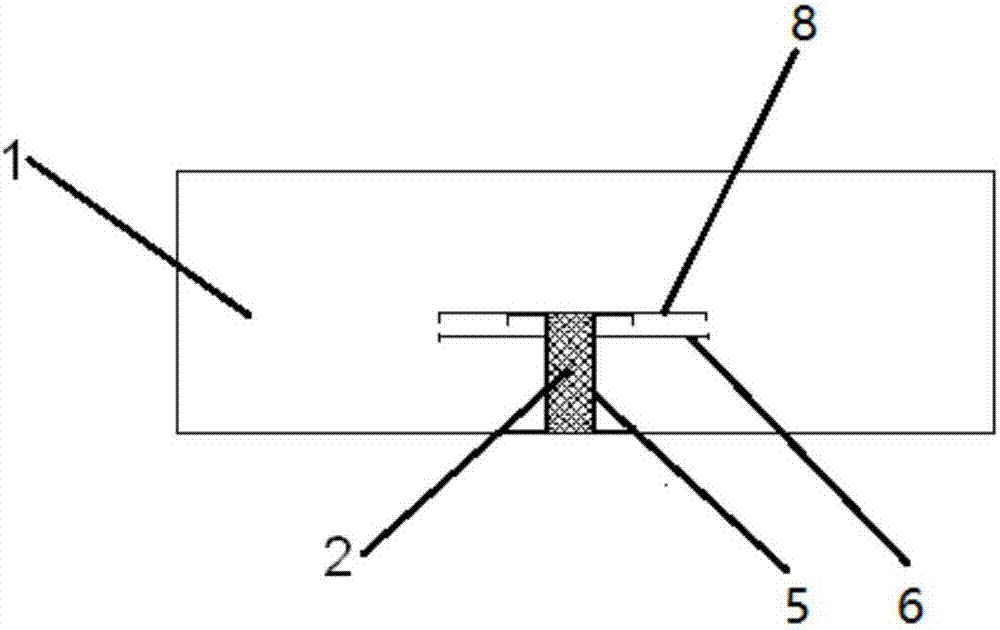

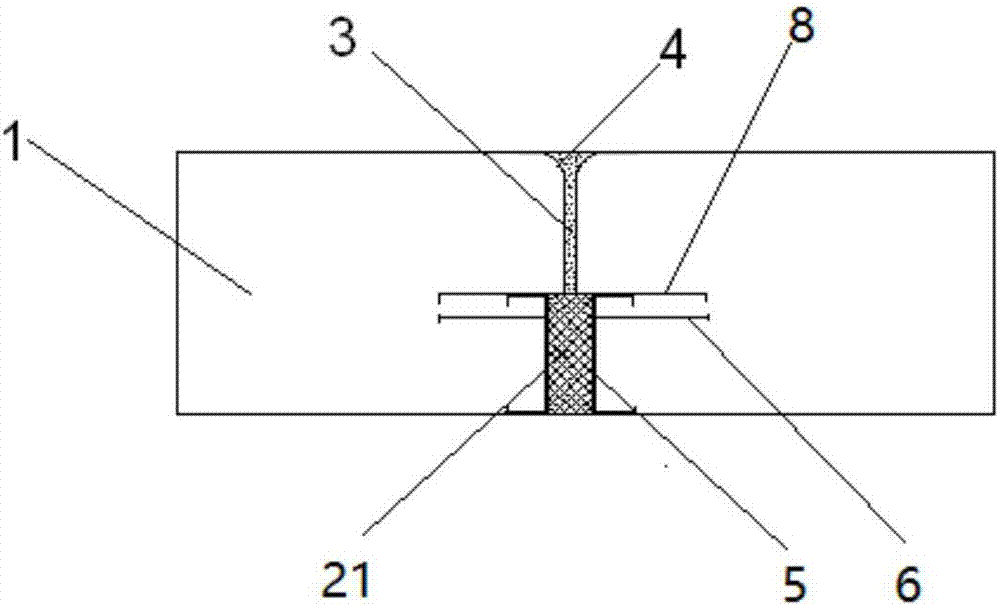

[0033] Refer to attached figure 1 As shown, the concrete slab 1 of the present invention includes invisible expansion and deformation joints 2 , and the invisible expansion and deformation joints 2 extend from the bottom to the top of the concrete slab 1 and do not reach the top of the concrete slab 1 . That is to say, the lower part of the concrete slab 1 is provided with invisible expansion and deformation joints, and the upper part of the concrete slab is a complete concrete surface, and no joint gaps can be seen on the top of the concrete slab.

[0034] Wherein, the height of the invisible expansion deformation joint 2 is less than or equal to 1 / 2 of the height of the concrete slab 1, and its width is 1-4 cm.

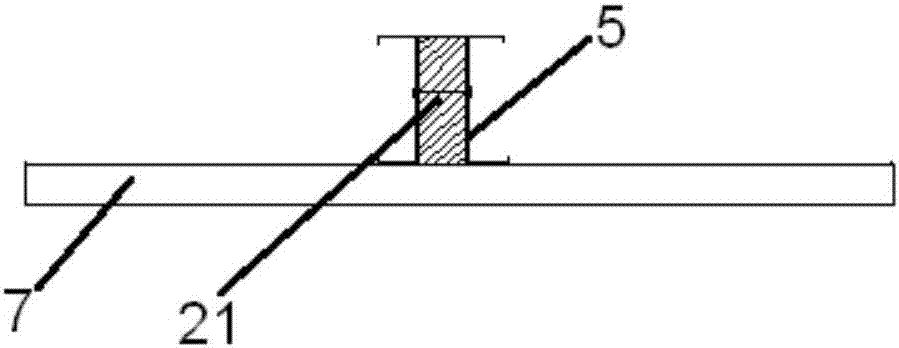

[0035] Refer to attached figure 2 As shown, in this embodiment, the invisible expansion and deformation joint 2 is filled with a stretchable board 21, and the stretchable board 21 is made of polyplastic board, polypropylene board, extruded board or polystyrene boa...

Embodiment 2

[0042] The difference between the second embodiment and the first embodiment above is that the invisible expansion deformation joint 2 is a cavity supported by a supporting template 22, and the supporting template 22 is made of steel plate or plastic material. Figure 4 shown. When cutting the top of the concrete slab, only need to cut and cut the top of the support template 22, the function of the invisible expansion deformation joint can be realized. Other parts or structures are the same as those in Embodiment 1, and will not be repeated here.

[0043] The preparation method of the above-mentioned concrete slab 1 with invisible expansion deformation joint 2 comprises the following steps:

[0044] (1) A cushion of suitable size is preset according to the size of the pre-prepared concrete slab, and the position of the invisible expansion deformation joint is arranged on the cushion;

[0045] (2) Fix the support formwork 22 or the stretchable plate 21 at the position of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com