Structure and method for renovation of hidden framing glass curtain wall

A technology of hidden frame glass curtain wall and curtain wall, applied in the direction of wall, building components, building structure, etc., can solve the problems of structural adhesive aging and cracking, glass falling off, and the existing hidden frame glass curtain wall cannot be completely demolished and rebuilt.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

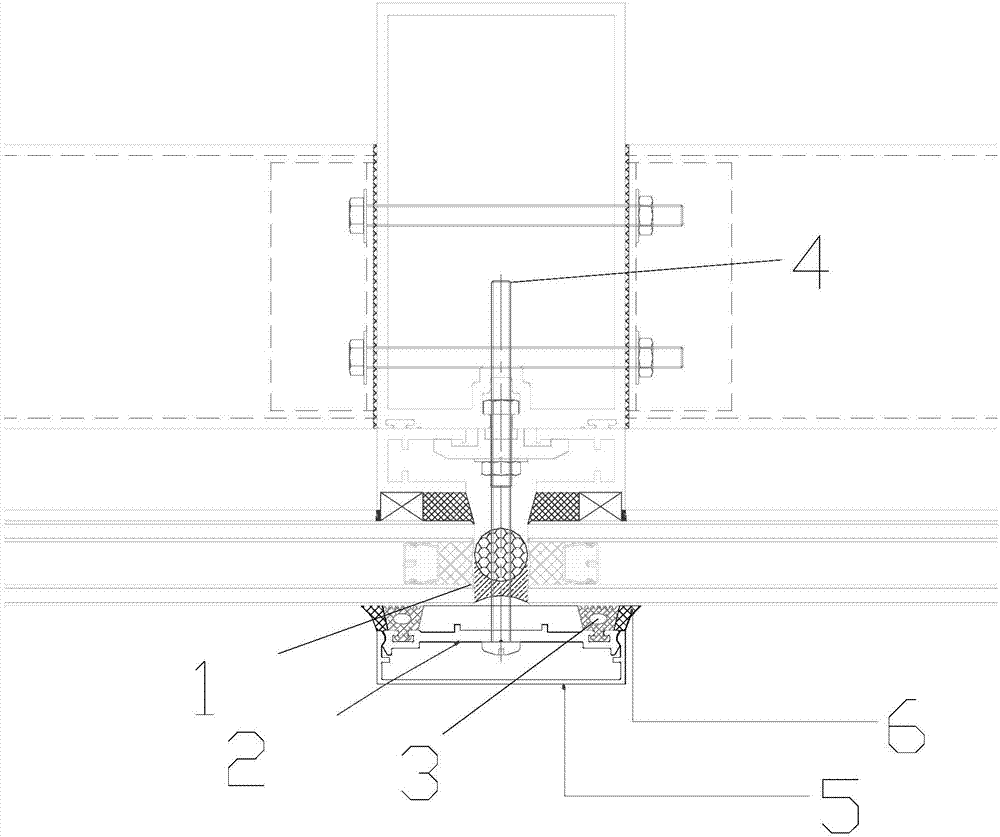

[0020] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

[0021] A method for reforming a hidden frame glass curtain wall, comprising the following steps:

[0022] S1: According to different construction requirements, design special pressure plate and decorative cover, cut the pressure plate into 200-300mm / section, and process ¢5 through holes 50mm away from both ends;

[0023] S2: Partially cut off the weather-resistant adhesive of the hidden frame glass curtain wall, and the specific position matches the length of the pressing plate and the installation distance of the pressing plate, so as to facilitate drilling on the main keel of the curtain wall; process a through hole of ¢4.5 on the main keel of the curtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com