System for measuring top beam support height and attitude of hydraulic support and method thereof

A technology of hydraulic support and measurement system, which is applied in the direction of measuring device, measuring inclination, surveying and navigation, etc. It can solve the problems of angle value error, low achievability, loss of measurement accuracy, etc., so as to ensure normal work and guarantee The effect of measurement accuracy and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described below.

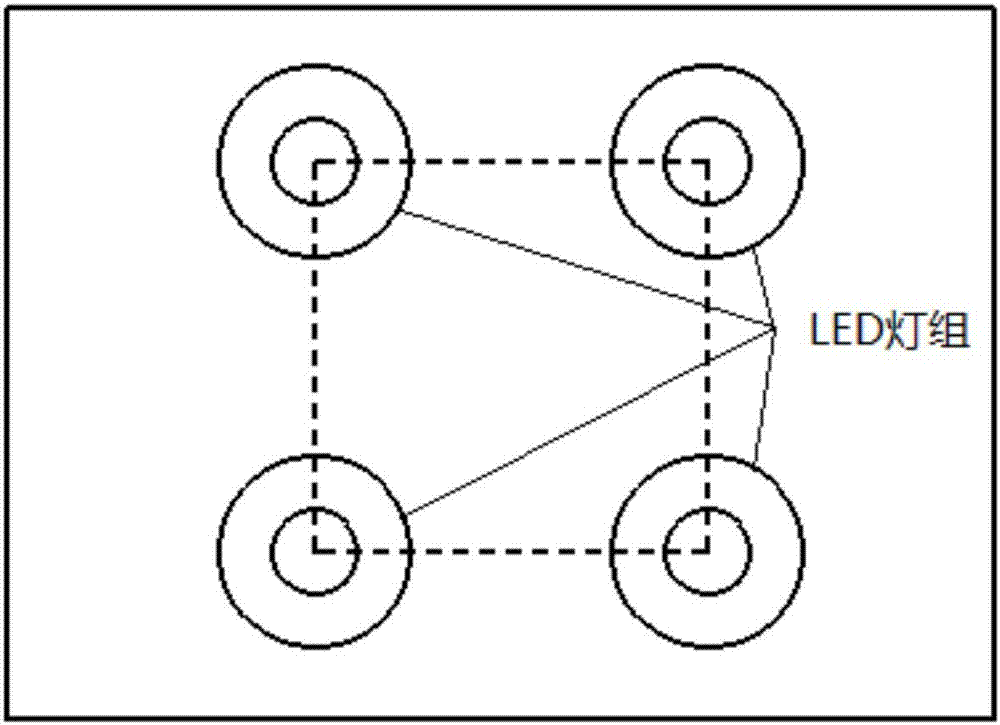

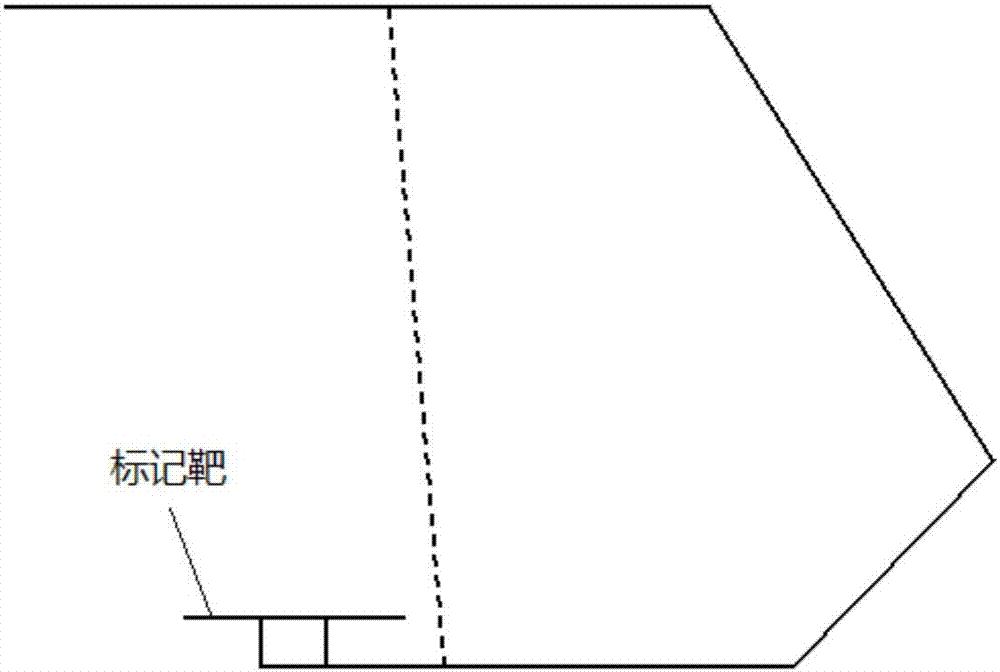

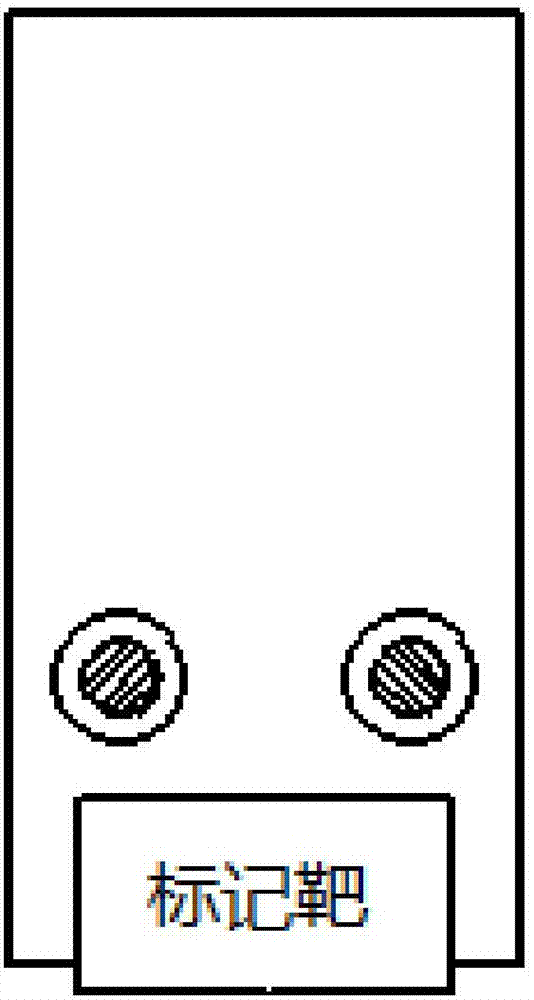

[0048] Such as Figure 1 to Figure 5 As shown, a measurement system for the height and attitude of the top beam of the hydraulic support includes a machine vision module and an attitude compensation module used in conjunction with it. The machine vision module includes a mine explosion-proof casing, a mine camera and a microcomputer I , the mine explosion-proof shell is installed at the lower part of the hydraulic support top beam, the microcomputer I is set in the mine explosion-proof shell, and the mine camera is installed at the lower end of the explosion-proof shell; the attitude compensation module includes a marking target, a microcomputer II and a MEMS inclination sensor , the marking target is set on the bottom plate of the hydraulic support, the upper surface of the marking target is parallel to the surface of the bottom plate of the hydraulic support, so that the machine vision module can accurately coll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com