Method for performing pull-off test on ultraviolet-aged asphalt and asphalt mortar

A technology of drawing test and aging asphalt, which is applied in the direction of measuring devices, instruments, and mechanical devices, etc., can solve the problems of different understanding and judgment of microboiling state, affect the test results, and be difficult to estimate accurately, etc. Less sample demand, accurate test effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

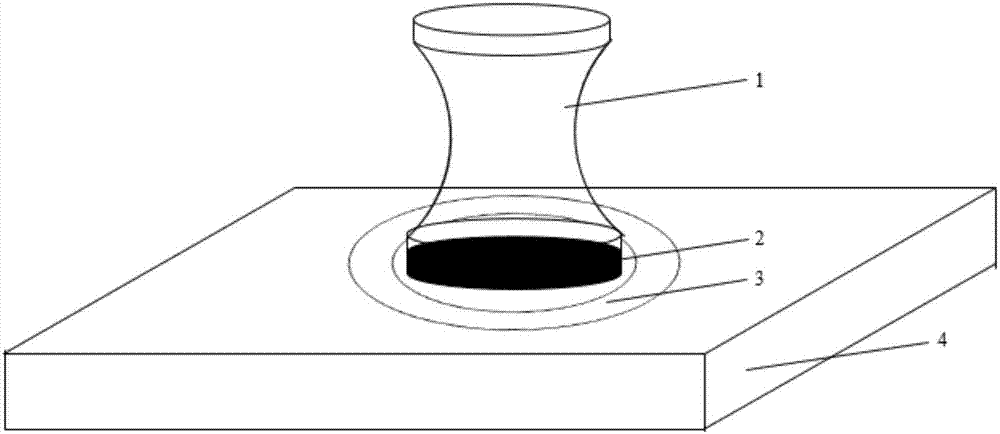

[0024] A pull-out test method for ultraviolet light aging asphalt and asphalt mortar, which selects Shell 70# base asphalt and rubber asphalt as research objects, and specifically includes the following steps:

[0025] (1) Thermal aging of asphalt and asphalt mortar samples

[0026] Put the asphalt and asphalt mortar samples into the oven, and control the temperature of the oven to 163°C for 5 hours;

[0027] (2) UV aging of asphalt and asphalt mortar samples

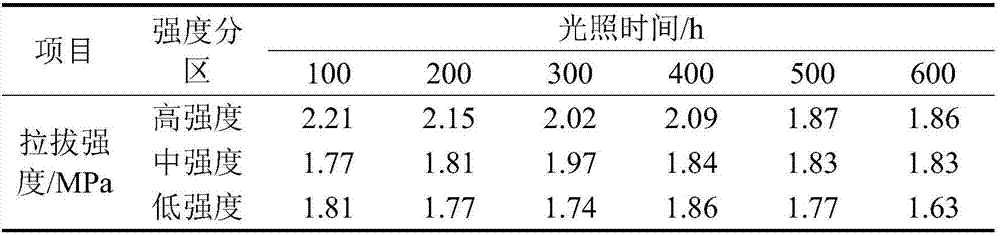

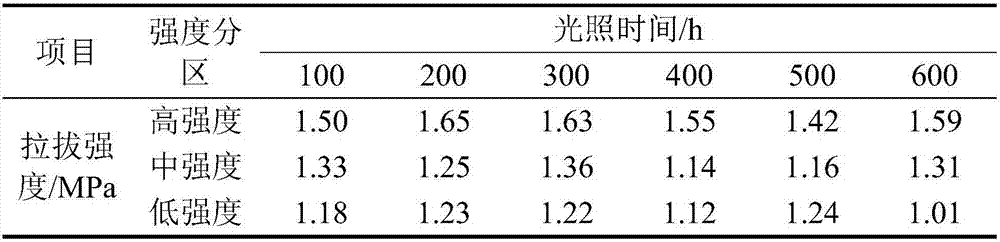

[0028] Put the asphalt and asphalt mortar samples into a circular sample pan (r60mm), the thickness of the sample is 1mm, and the circular sample pan is divided into high strength (r=0~20mm) and medium strength (r=0~20mm) with the center of the circle as the center. r = 20 ~ 40mm), low intensity (r = 40 ~ 60mm) area, the highest ultraviolet light intensity is 400W / m 2 , the masses of asphalt and asphalt mortar were 1.31g, 3.66g, and 6.14g, respectively. A 125w reflective high-pressure mercury lamp is used as the ultr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com