Lithium-ion battery diaphragm, preparation method thereof and lithium-ion battery

A technology for lithium-ion batteries and diaphragms, which is applied in secondary batteries, battery pack parts, separators/films/diaphragms/spacers, etc., and can solve complex processing techniques, high process costs, and poor heat resistance of product films, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] The invention provides a preparation method of a lithium-ion battery separator, comprising: (1) melting and blending polyethylene, a pore forming agent, a crosslinking agent and a crosslinking aid to obtain a mixture A; (2) preparing the mixture A Forming into an initial film B, the gel content of the initial film B is less than 5% by weight; (3) performing high temperature crosslinking on the initial film B to form a crosslinked film C, the gel content of the crosslinked film C The glue content is 30-70% by weight; (4) stretching the crosslinked film C to obtain a stretched film D; (5) annealing the stretched film D to obtain a lithium-ion battery separator; wherein, the The melt index MI of the polyethylene is 0.02g / 10min~5g / 10min; relative to 100 parts by weight of the polyethylene, the amount of the crosslinking agent is 0.03~8 parts by weight, and the amount of the crosslinking aid It is 0.03 to 10 parts by weight.

[0020] According to the present invention, pref...

Embodiment 1

[0049] (1) Formula of polyethylene composition for lithium ion battery diaphragm:

[0050] The matrix resin is HDPE with MI=0.3g / 10min (density=0.960g / cm 3 ) 100 g, 0.7 g of 2,5-dimethyl-2,5-bis(tert-butylperoxy)hexane, and 1.1 g of triallyl isocyanurate.

[0051] (2) Lithium-ion battery diaphragm preparation:

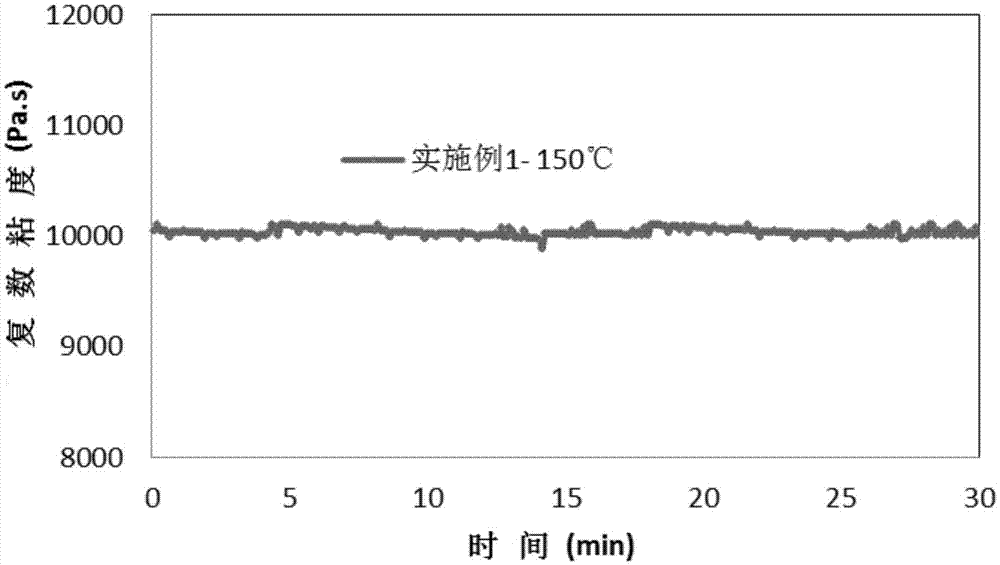

[0052] Each component that forms the above formula is extruded and granulated in a low-shear twin-screw extruder (length-to-diameter ratio is 18 / 1, and the rotating speed of the screw is 100 rpm) to obtain mixture A, and the blending temperature is 140 °C, while testing the rheological curve of mixture A at 150 °C for 30 minutes, such as figure 1 shown. Depend on figure 1 It can be seen that during the melt blending process, the viscosity of the mixture A can remain basically unchanged under the test conditions, indicating that the formulation composition has good processing thermal stability and no crosslinking occurs. Mixture A was sampled and determined to have...

Embodiment 2

[0060] (1) Formula of polyethylene composition for lithium ion battery diaphragm:

[0061] The matrix resin is HDPE with MI=2g / 10min (density=0.955g / cm 3 ) 100 g, 0.7 g of 2,5-dimethyl-2,5-bis(tert-butylperoxy)hexane, and 1.1 g of triallyl isocyanurate.

[0062] (2) Lithium-ion battery diaphragm preparation:

[0063] Each component that forms the above formula is extruded and granulated in a low-shear twin-screw extruder (length-to-diameter ratio is 18 / 1, and the rotating speed of the screw is 100 rpm) to obtain mixture A, and the blending temperature is 150 ℃, the rheological curve of the test mixture A is the same as that in Example 1, and basically remains the same, indicating that the processing heat stability of this formula composition is good, and no crosslinking occurs. Mixture A was sampled and determined to have a gel content of 0.5% by weight;

[0064] The mixture A was molded by tableting (the molding temperature was 145° C.) to obtain an initial film B, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap