Multifunctional feed inlet structure

A feed port, multi-functional technology, applied in the field of machinery, can solve the problems of single feed port function and simple structure of the feed port, and achieve the effects of broad market space, easy production and increased friction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

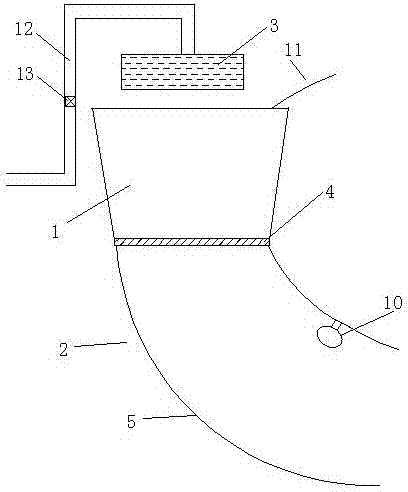

[0018] A multi-functional feeding port structure, comprising a trumpet-shaped feeding hopper 1, an arc-shaped feeding channel 2 connected to the bottom of the feeding hopper, a spray head 3 is arranged above the feeding hopper, and a cleaning plate is arranged at the bottom of the feeding hopper 4. The lower cavity wall 5 inside the arc-shaped feeding channel is a hollow structure, and the upper cavity wall inside the arc-shaped feeding channel is provided with a fan 10 .

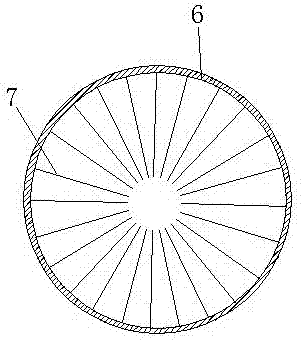

[0019] The cleaning disc includes an annular fixed disc 6 and several cleaning rods 7. The outer wall of the fixed disc is connected with the inner wall at the bottom of the feed hopper. The cleaning rod includes an elastic connecting rod body 8 and a friction head 9. One end of the elastic connecting rod body is connected with the inner wall of the fixed disc. The other end is equipped with a friction head, which points to the center of the fixed disk. The circumference of the rubbing head forms a circle (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com