Manufacturing system for wearing product

A technology for manufacturing systems and articles, applied in apparel, underwear, baby underwear, etc., can solve the problem of inability to achieve mass production of elastic waistlines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

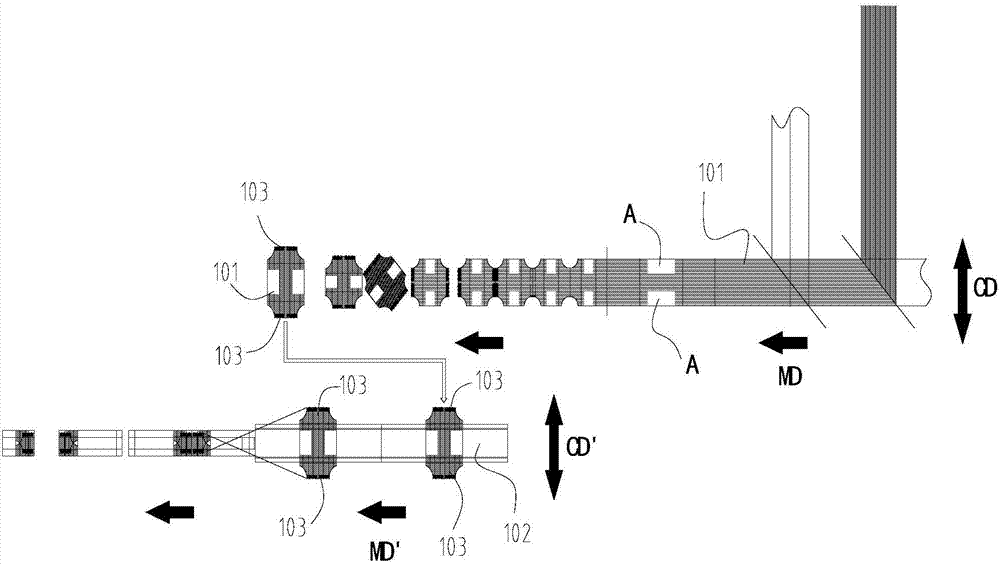

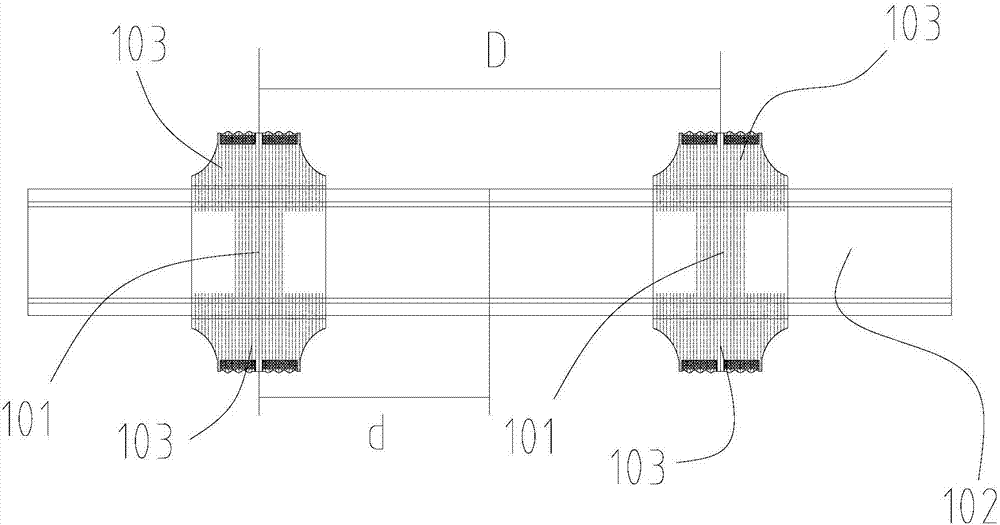

[0056] See figure 1 , Figure 8 , A manufacturing system for wearing articles, which is used to release the tension of the strip-shaped elastic sheet 101 that can be stretched in the process direction MD and can be stretched in the process direction MD and processed into a certain specification shape, and then it is turned and expanded to On the absorbing main body 102, the flaps 103 on both sides of the elastic sheet are folded by the discontinuous material packaging device. The above-mentioned elastic sheet 101 is composed of an upper non-woven fabric, a lower non-woven fabric and an elastic elastic band placed between the two non-woven fabrics.

[0057] The manufacturing system of wearing articles has:

[0058] A tension conveying device is used to stretch the belt-shaped elastic sheet 101 and convey it in the process direction MD. It is also provided with a processing unit that cuts the local elastic rubber band on the elastic sheet 101. The processing unit cuts the elastic she...

Embodiment 2

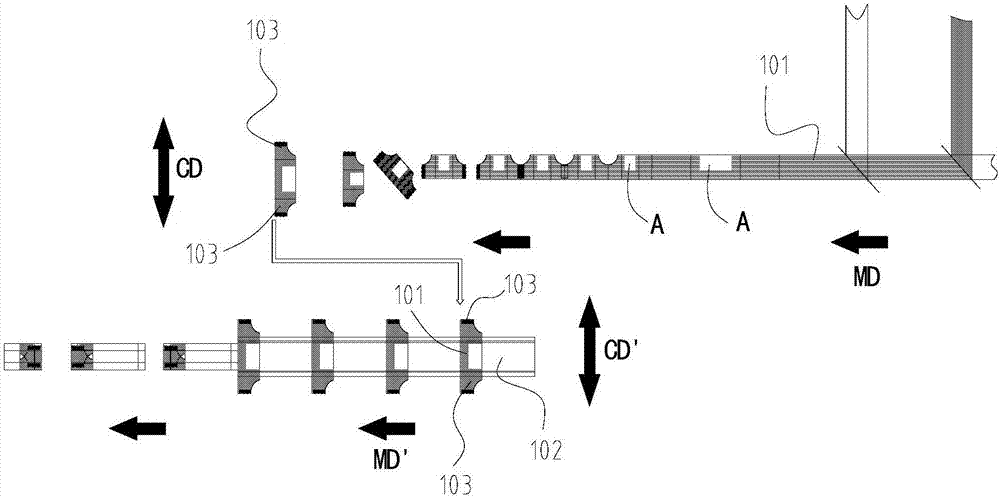

[0089] See image 3 , Picture 9 , A manufacturing system for wearing articles, in which the arc cutting device 10 in the tension-free conveying device 14 is used for arc cutting on one side of the elastic sheet 101 in the width direction CD.

[0090] Such as Figure 7 As shown, the elastic sheet 101 is conveyed from the upstream side 15 to the downstream side 16 through the waist attachment compound device 12, the arc cutting device 10, the waste suction device 11, and the waist cutting device 13 under the drive of the tension-free conveying device 14.

[0091] See Figure 12 to 13 , The steering expansion device includes two mutually matched variable speed steering structure 91 and variable speed expansion structure 92, and then complete the steering and expansion action of the elastic sheet step by step.

[0092] The variable-speed steering structure 91 is used to rotate the cut elastic sheet by 90° and convey it to the variable-speed expansion structure. Since this part of the str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com