Industrial control ultrasonic probe and method for improving industrial control ultrasonic probe

An industrial control, single-layer technology, applied in the field of ultrasonic probes, can solve problems such as low sensitivity and unsatisfactory sensitivity, and achieve the effects of improving sensitivity, increasing sensitivity and reliable adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

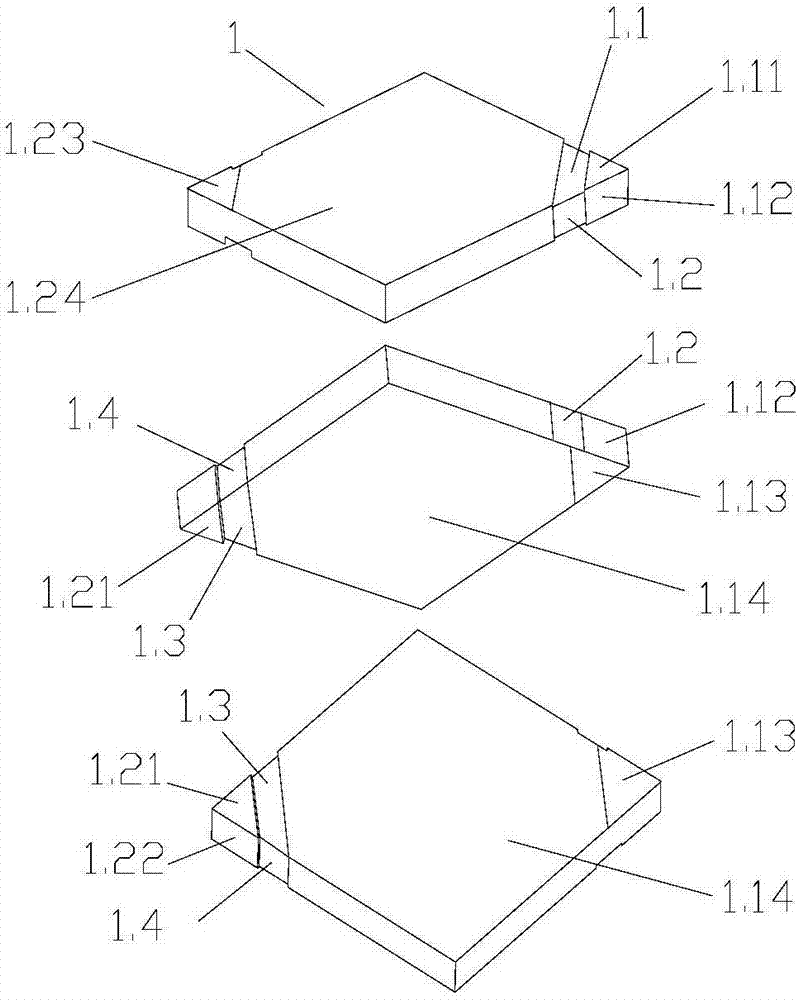

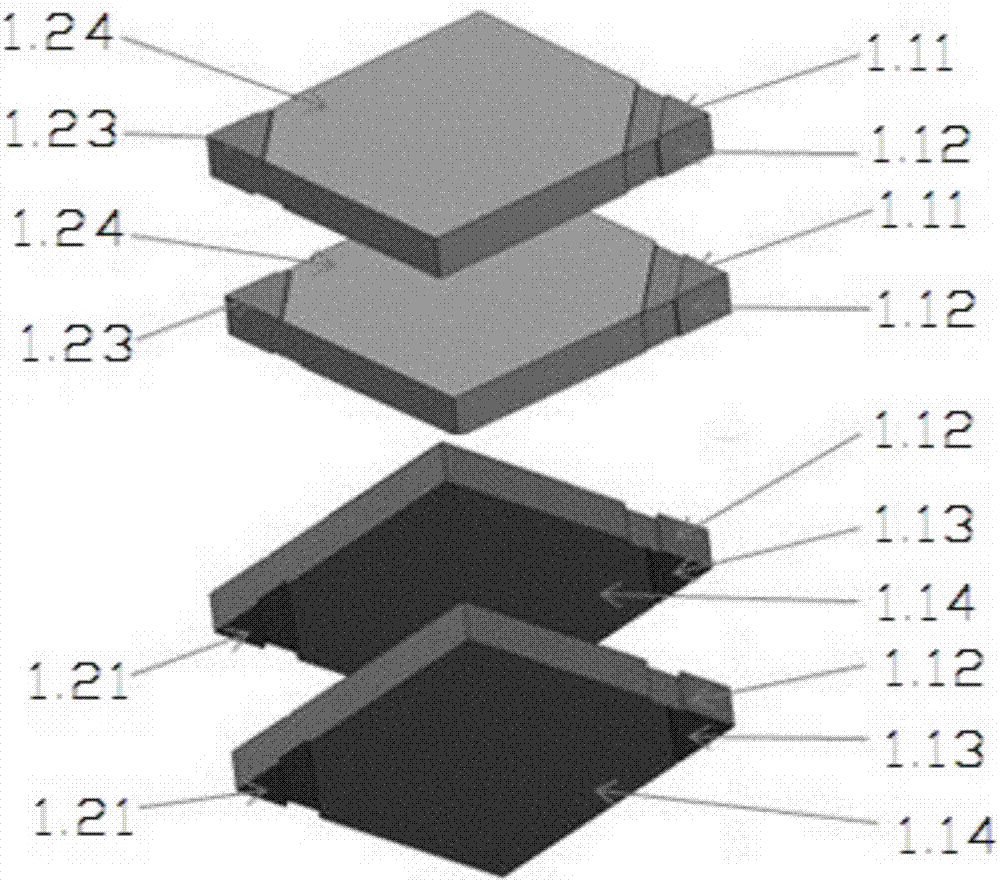

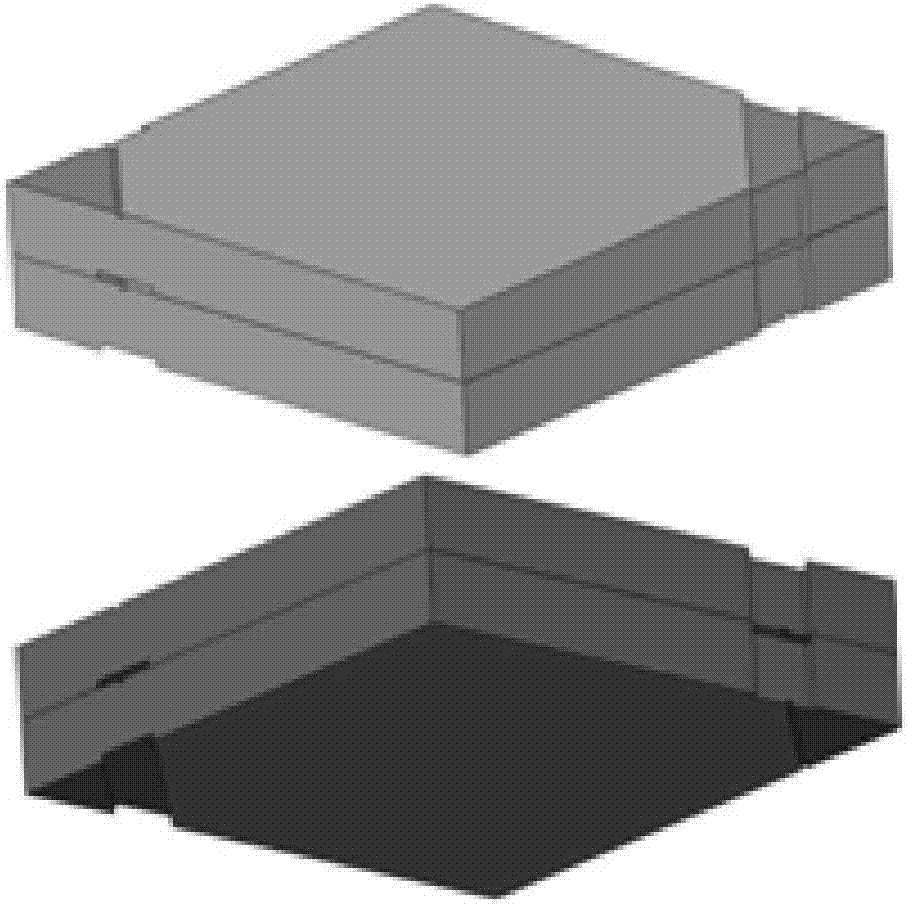

[0022] Embodiment 1: Piezoelectric ceramic sheet, with reference to Figure 1 to Figure 3 As shown, it consists of two single-layer ceramic sheets 1 stacked up and down. A downward frontal groove 1.1 is provided at a corner of the front side of the single-layer ceramic sheet 1. The two sides of the corner form a concave positive side groove 1.2, and the positive groove 1.1 and the positive side groove 1.2 have the same concave depth and width, and the positive groove 1.1 and the positive side groove 1.2 divide the corner into a single layer In the first electrode area of the ceramic sheet 1, the upward surface of the first electrode area is the first positive electrode surface 1.11, the downward surface of the first electrode area is the third positive electrode surface 1.13, and the left side of the first electrode area is the first positive electrode surface 1.11. The two positive electrode surfaces 1.12, the first positive electrode surface 1.11, the second positive elect...

Embodiment 2

[0025]Embodiment 2: piezoelectric ceramic sheet, with reference to Figure 1 to Figure 3 As shown, it is composed of four single-layer ceramic sheets 1 stacked up and down. A downward frontal groove 1.1 is provided at a corner of the front side of the single-layer ceramic sheet 1, and the two ends of the frontal groove 1.1 extend to the two sides of the corner and are on the corner. The two sides of the corner form a concave positive side groove 1.2, and the positive groove 1.1 and the positive side groove 1.2 have the same concave depth and width, and the positive groove 1.1 and the positive side groove 1.2 divide the corner into a single layer In the first electrode area of the ceramic sheet 1, the upward surface of the first electrode area is the first positive electrode surface 1.11, the downward surface of the first electrode area is the third positive electrode surface 1.13, and the left side of the first electrode area is the first positive electrode surface 1.11. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com