Cloth winding device for textile production

A winding device and cloth technology, which is applied in the direction of winding strips, thin material handling, transportation and packaging, etc., can solve the problems of inconvenient use, slow cutting speed, and affecting working speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

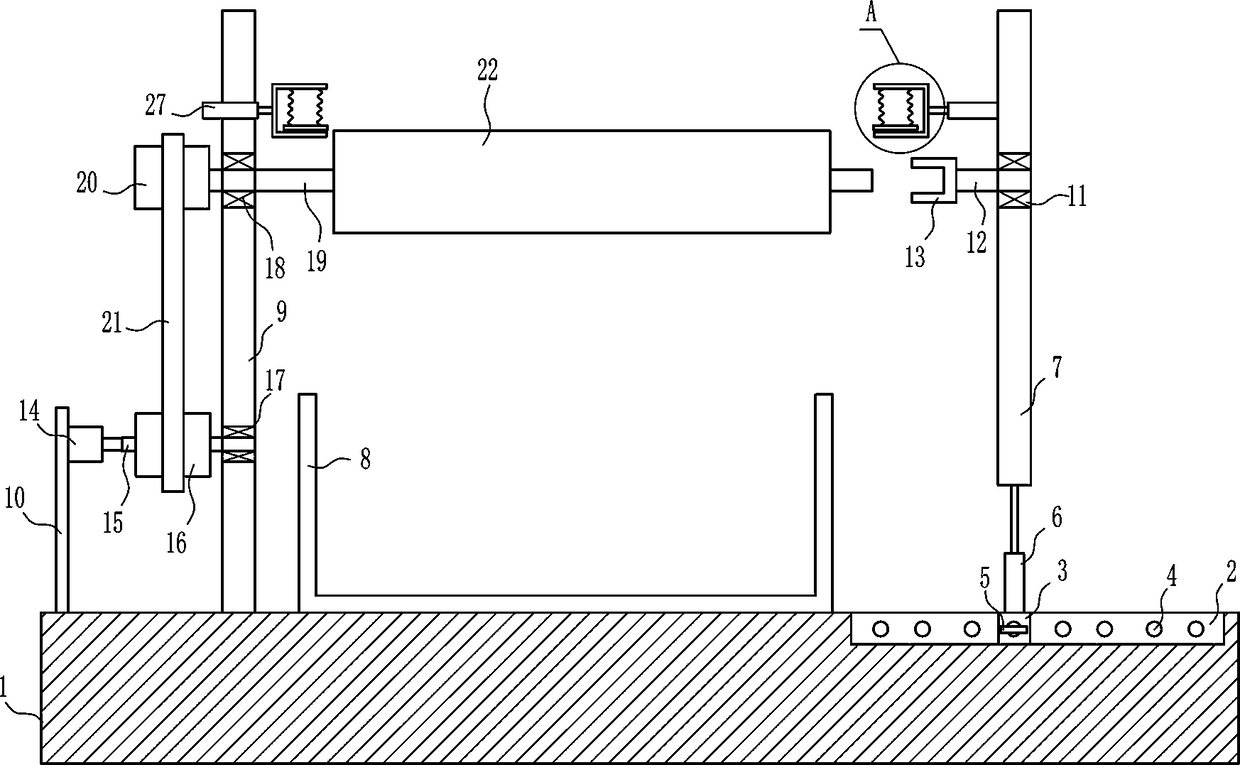

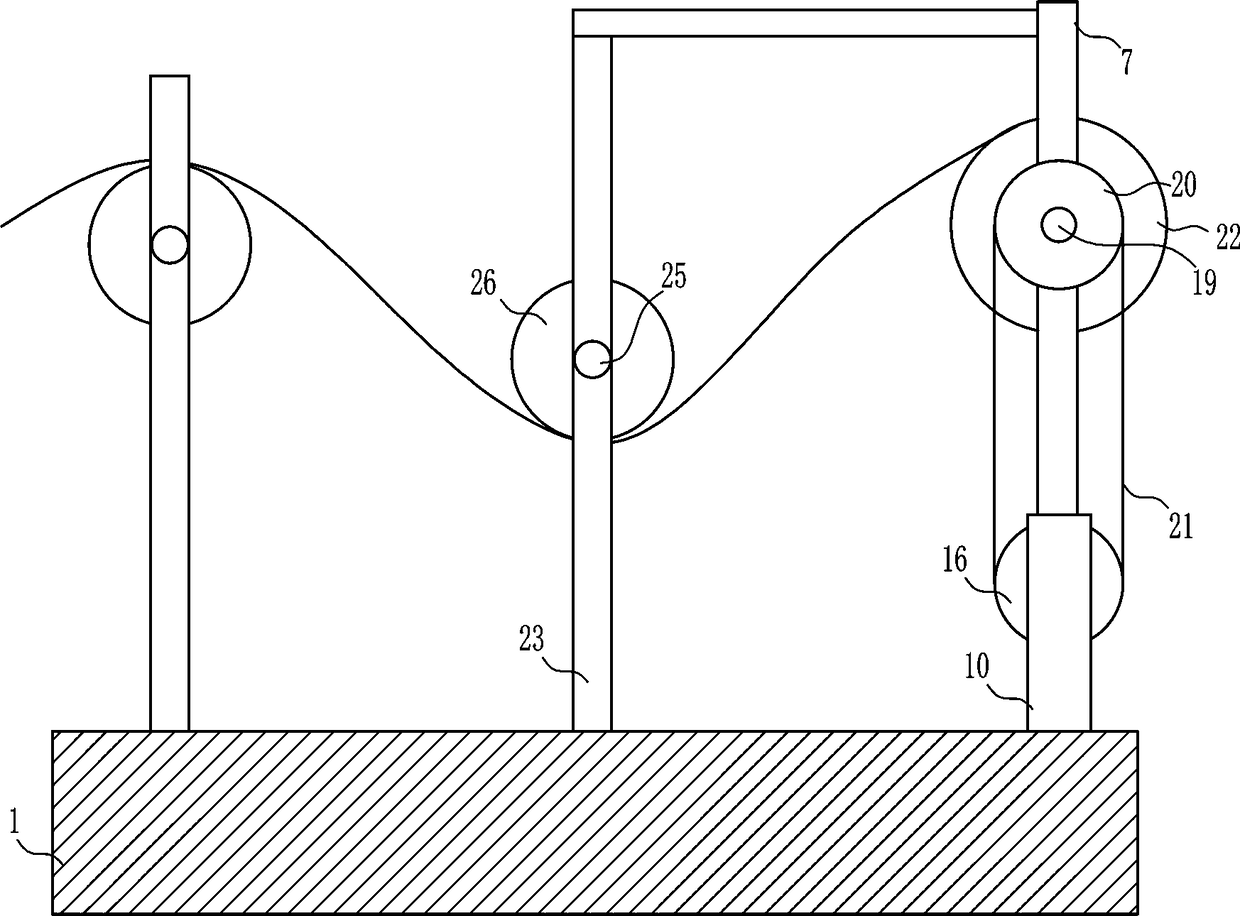

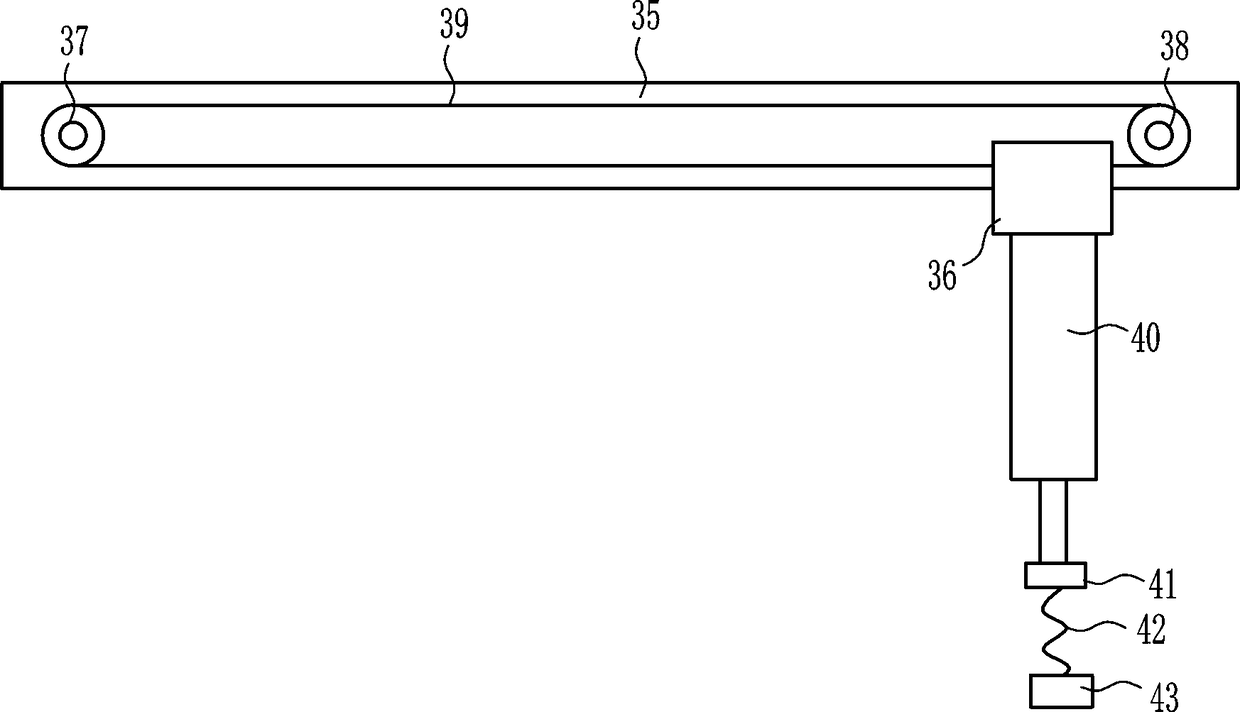

[0039] A cloth winding device for textile production, such as Figure 1-9 As shown, it includes a base 1, a first slider 3, a screw 5, a first cylinder 6, a right side plate 7, a placement frame 8, a left side plate 9, a fixed plate 10, a first bearing seat 11, and a first rotating shaft 12 , thumb cylinder 13, first motor 14, second rotating shaft 15, first pulley 16, second bearing seat 17, third bearing seat 18, third rotating shaft 19, second pulley 20, flat belt 21 and first roller 22 , There is a chute 2 on the right side of the base 1, a first slider 3 is provided in the chute 2, the middle part of the first slider 3 and the front side of the base 1 on the front side of the chute 2 are evenly spaced with threaded holes 4. The threaded hole 4 is threadedly connected with the screw 5, the top of the first slider 3 is connected with the first cylinder 6 by means of bolt connection, the end of the telescopic rod of the first cylinder 6 is connected with the right side plate...

Embodiment 2

[0041] A cloth winding device for textile production, such as Figure 1-9 As shown, it includes a base 1, a first slider 3, a screw 5, a first cylinder 6, a right side plate 7, a placement frame 8, a left side plate 9, a fixed plate 10, a first bearing seat 11, and a first rotating shaft 12 , thumb cylinder 13, first motor 14, second rotating shaft 15, first pulley 16, second bearing seat 17, third bearing seat 18, third rotating shaft 19, second pulley 20, flat belt 21 and first roller 22 , There is a chute 2 on the right side of the base 1, a first slider 3 is provided in the chute 2, the middle part of the first slider 3 and the front side of the base 1 on the front side of the chute 2 are evenly spaced with threaded holes 4. The threaded hole 4 is threadedly connected with the screw 5, the top of the first slider 3 is connected with the first cylinder 6 by means of bolt connection, the end of the telescopic rod of the first cylinder 6 is connected with the right side plate...

Embodiment 3

[0044] A cloth winding device for textile production, such as Figure 1-9 As shown, it includes a base 1, a first slider 3, a screw 5, a first cylinder 6, a right side plate 7, a placement frame 8, a left side plate 9, a fixed plate 10, a first bearing seat 11, and a first rotating shaft 12 , thumb cylinder 13, first motor 14, second rotating shaft 15, first pulley 16, second bearing seat 17, third bearing seat 18, third rotating shaft 19, second pulley 20, flat belt 21 and first roller 22 , There is a chute 2 on the right side of the base 1, a first slider 3 is provided in the chute 2, the middle part of the first slider 3 and the front side of the base 1 on the front side of the chute 2 are evenly spaced with threaded holes 4. The threaded hole 4 is threadedly connected with the screw 5, the top of the first slider 3 is connected with the first cylinder 6 by means of bolt connection, the end of the telescopic rod of the first cylinder 6 is connected with the right side plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com