Auxiliary flexible tooling and method for detection of rail vehicle axlebox spring adhesion strength

A technology for axlebox springs and adhesion strength, which is applied in the detection of the adhesion strength of rail vehicle axlebox springs and the field of adhesion strength detection of rail vehicle axlebox springs. Intensity and other problems, to save production space and management manpower, simple operation of the detection process, save the effect of storage and management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

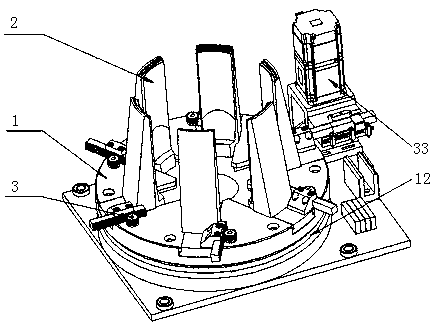

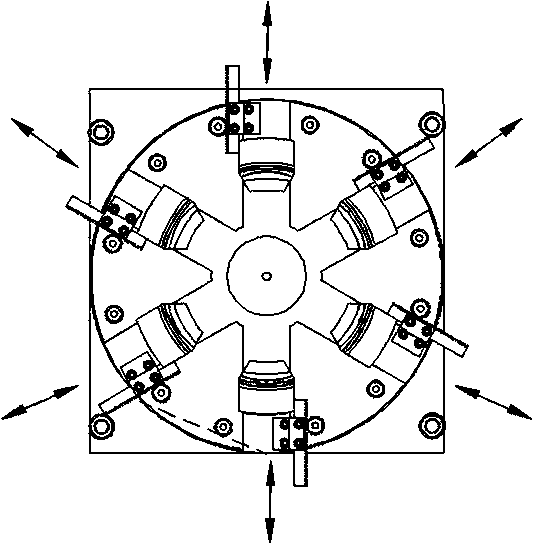

[0043] Combine below Figure 2 to Figure 10 Embodiments of the present invention are described in detail.

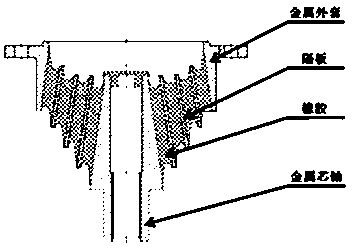

[0044] Auxiliary flexible tooling for detecting the adhesion strength of axlebox springs of rail vehicles, including a circular chassis 1 arranged horizontally, a support frame 2 arranged on the chassis 1 for supporting the axlebox springs, and a support frame 2 for adjusting the position of the support frame 2 on the chassis 1. The position adjustment power mechanism 3 in the upper position, the opening and closing of the position adjustment power mechanism 3 is coordinated and controlled by an external control system, and it is characterized in that the support frame 2 is composed of at least two support arms 21. The same circumferential line is distributed at intervals, the position adjustment power mechanism 3 is connected to the support arm 21 in transmission, and the position adjustment power mechanism 3 drives several support arms 21 to move synchronously along th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com