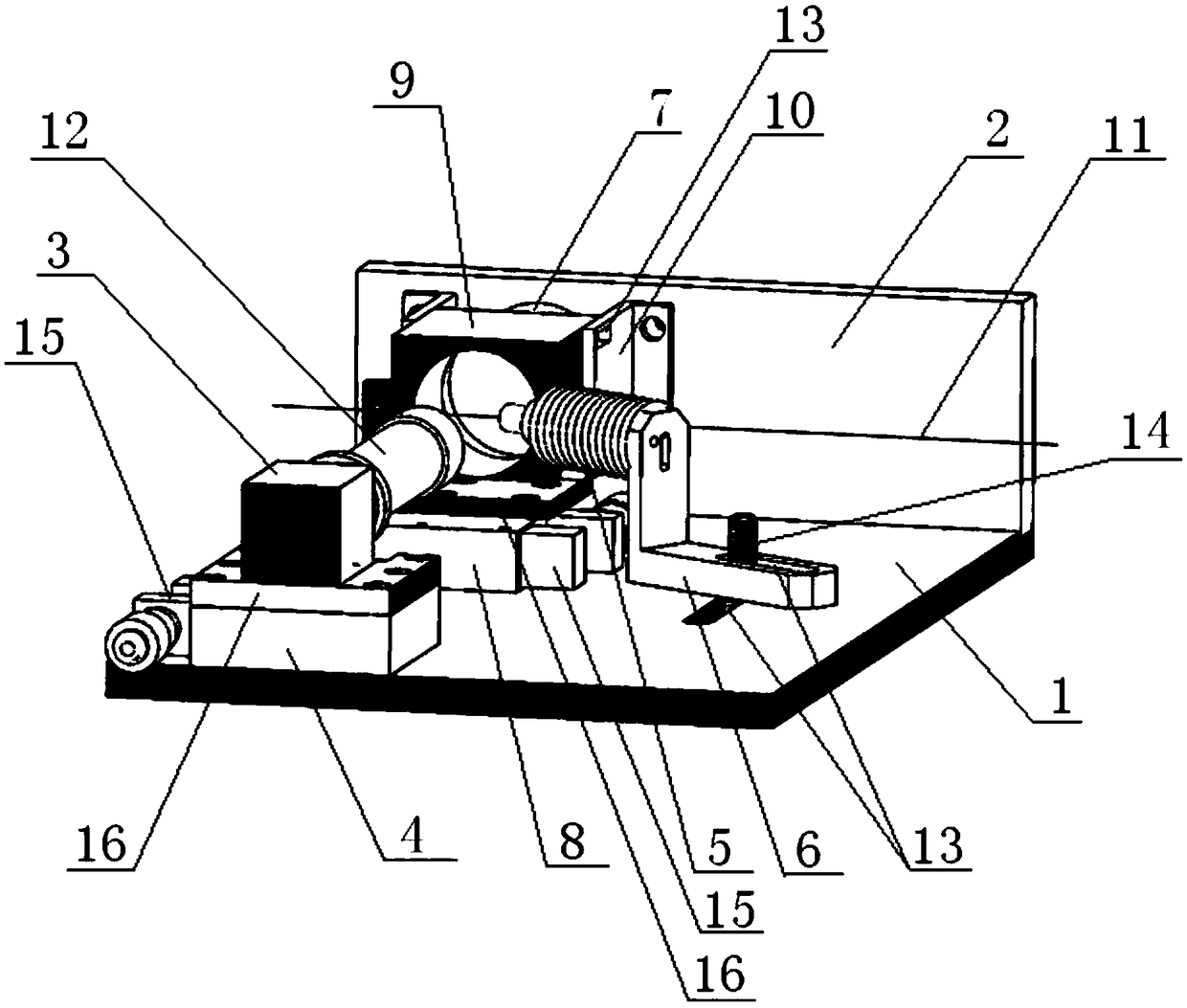

A diamond wire saw online detection device

A technology of diamond wire saw and detection device, which is applied in the direction of measuring device, optical device, fine working device, etc., to achieve the effect of convenient use, simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

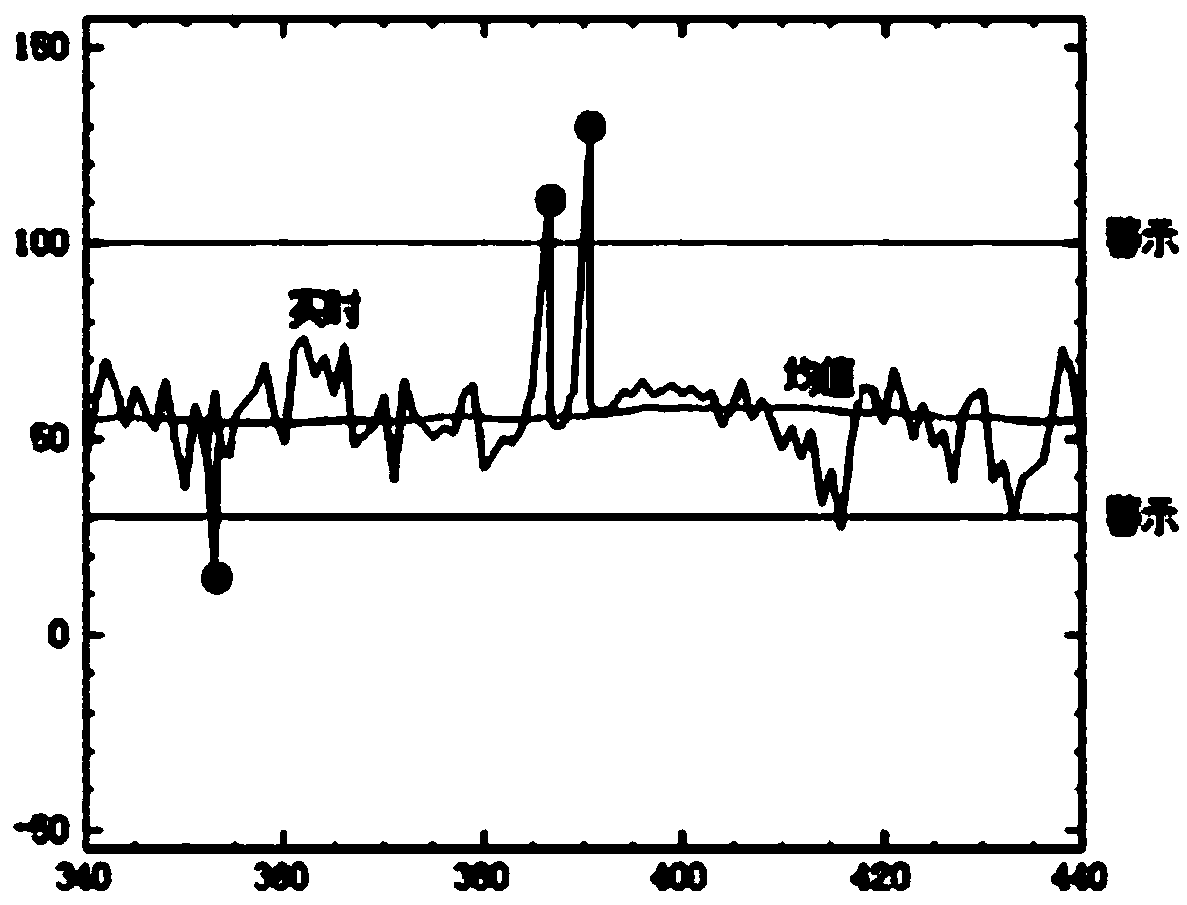

[0033] When in use, the light source controller senses and adjusts the brightness of the main light source and the backlight source, and controls the position adjustment of the camera installation slide table and the backlight installation slide table through the industrial computer, as well as the telescopic focusing of the camera lens to ensure clear imaging; when monitoring When the wire speed of the diamond wire saw drops to a low speed (close to zero), the diamond wire saw slicer supplies the camera with a 5v-24v level to trigger the camera to capture images with a rising edge. Due to the very high line speed of the cutting machine, the peak line speed is as high as 25m / s or more. Under high-speed conditions, the exposure time of the camera is required to be extremely short. In order to ensure clear imaging and reduce the cost of using a high-speed camera, according to the principle of reciprocating cutting of the diamond wire of the microtome, when the wire is reversing, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com