Stiffness gradient trigger gift box packing machine

A trigger type, box packaging technology, applied in the direction of packaging, transportation packaging, transportation and packaging, etc., can solve the problems of packaging failure, distracting crank mechanism thrust, long process time, etc., to achieve reduced packaging time, reliable and successful packaging process high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

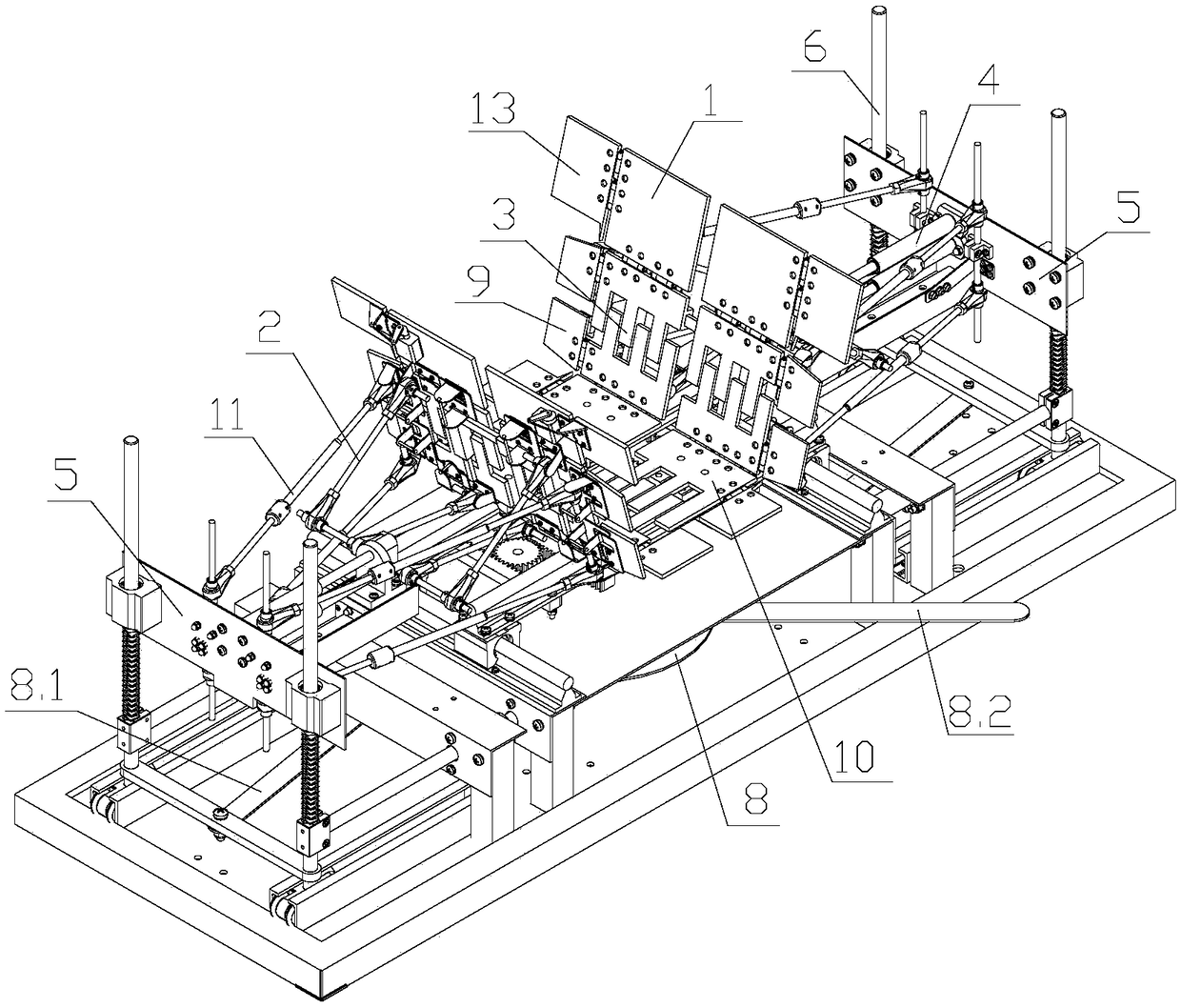

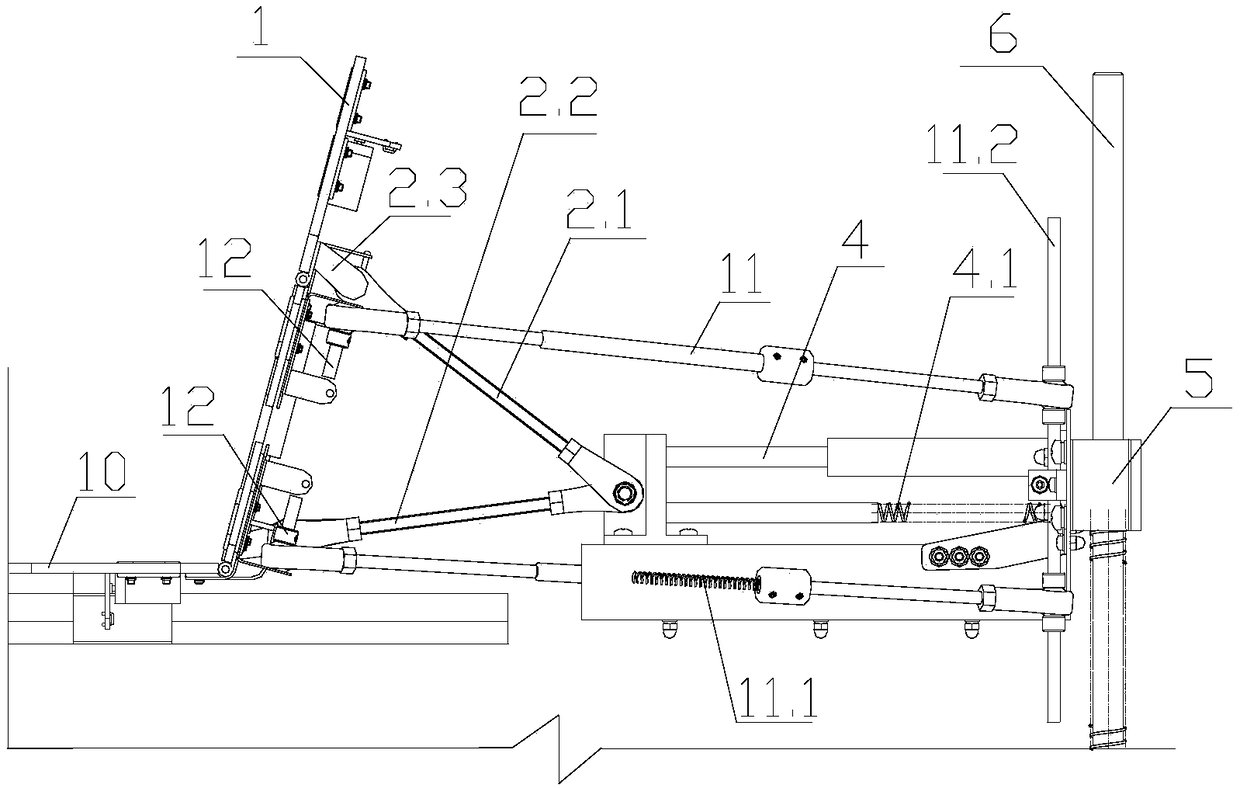

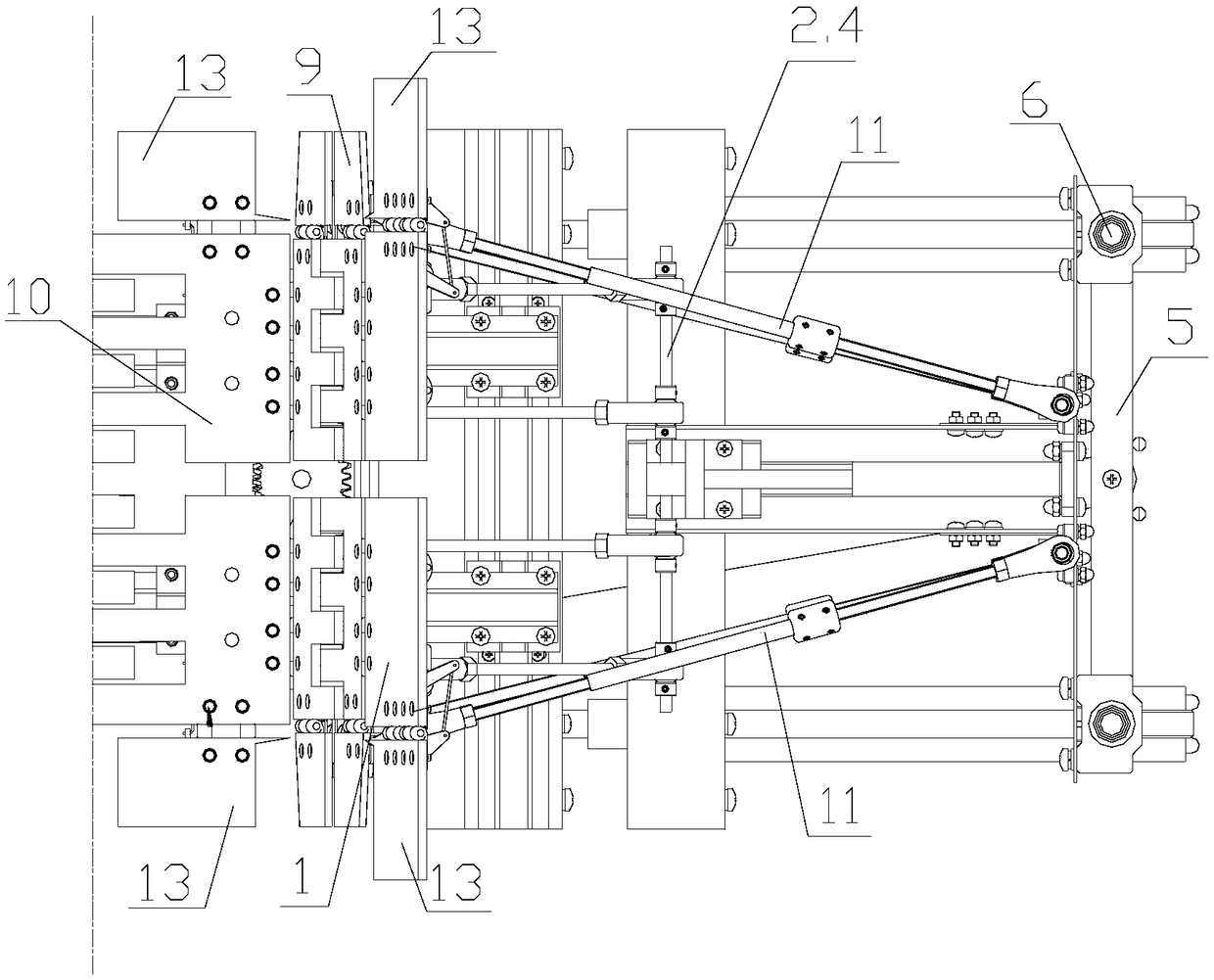

[0037] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

[0038] Such as Figures 1 to 4 As shown: the stiffness gradient trigger type gift box packaging machine according to the present invention includes a base and a packaging mechanism. The base is mainly composed of a centering crank slider mechanism 8. The packaging mechanism is divided into two sets symmetrically arranged in left and right mirror images Packaging agency.

[0039] The outer ends of the two cranks 8.1 of the centering crank slider mechanism 8 are respectively hinged with a connecting rod. The outer end of crank 8.1 is hinged in the middle part of connecting rod, and the two ends of connecting rod are respectively vertically fixed with a vertical rod. Therefore, there are four vertical bars in total. The two vertical rods on the same side form a set of vertical rod devices 6, and each set of vertical rod devices 6 correspond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com