Automatic cover taking and sealing device

An automatic, horizontally driven technology, applied in the direction of transportation and packaging, conveyor objects, etc., can solve the problems of large labor force, low innovation ability, troublesome operation, etc., and achieve the effect of overcoming large labor force, reducing danger, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the content of the present invention more clearly understood, the present invention will be further described in detail below based on specific embodiments and in conjunction with the accompanying drawings.

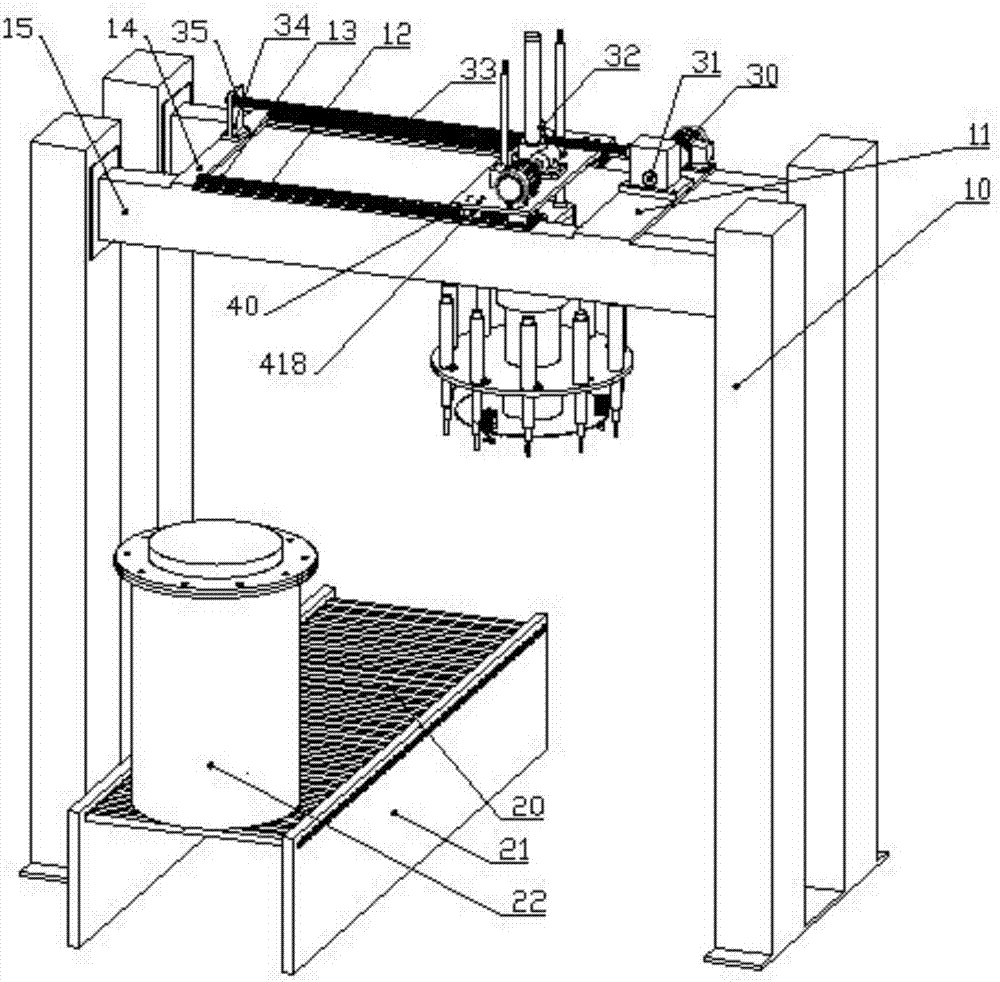

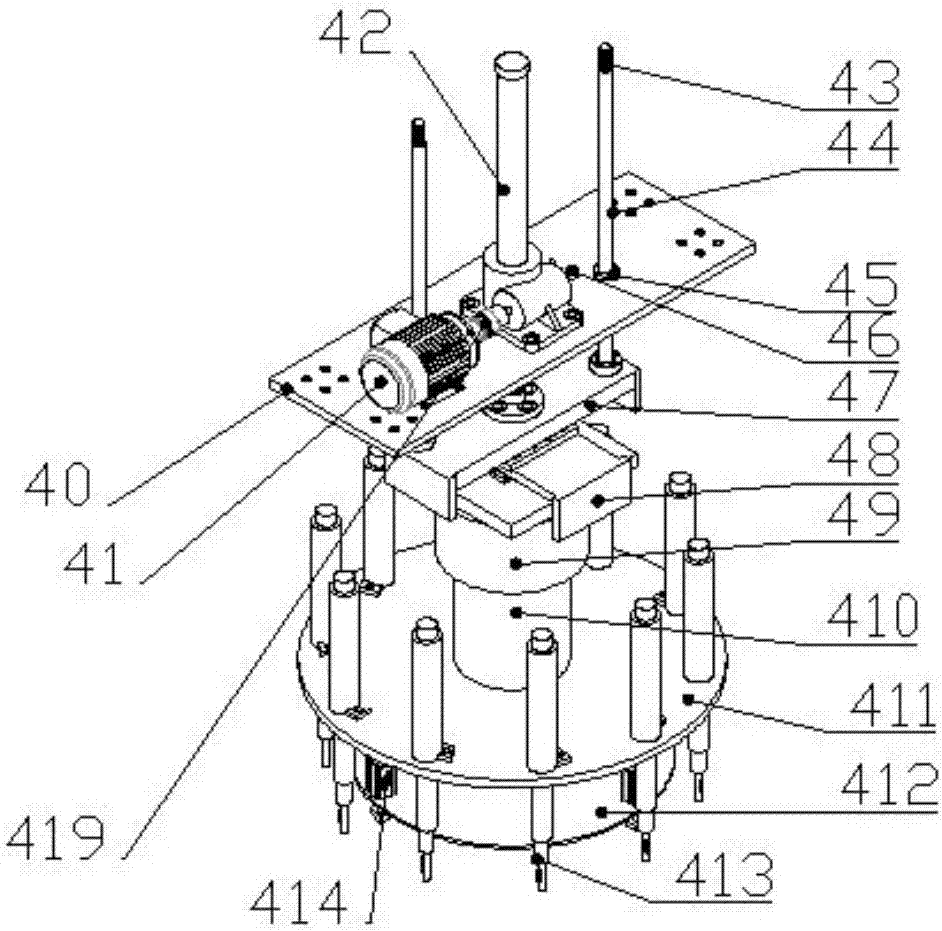

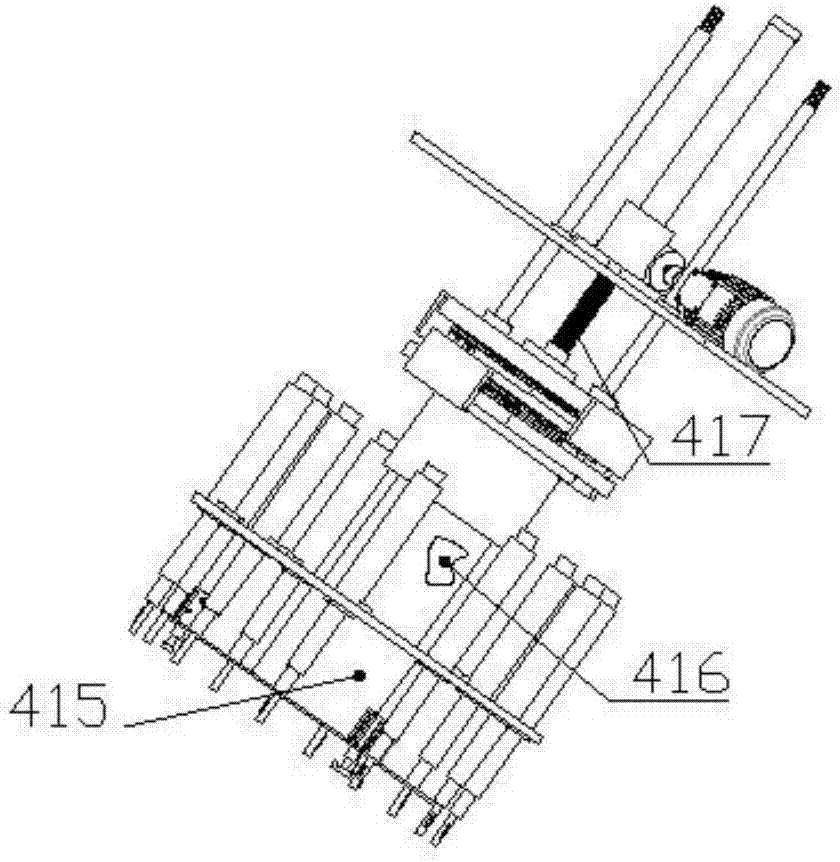

[0016] like Figure 1~4 As shown, an automatic capping device includes a support 10, a crossbeam 15 and a guide rail 13, the two ends of the crossbeam are fixedly connected with the support 10, the guide rail 13 is installed on the crossbeam 15, and also includes a horizontal adjustment mechanism and a tightening and lifting mechanism. The horizontal adjustment mechanism is made up of right connecting plate 11, left connecting plate 14, horizontal driving motor 30, worm gear 31, level adjusting screw 33, bearing 35, bearing block 34, nut seat 32 and connecting support plate 40, and connecting support plate 40 can be Mobilely installed on the guide rail 13, the left connecting plate 14 and the right connecting plate 11 are respectively fixed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com