Vacuum flashing and cooling device

A technology of cooling device and water cooling device, which is applied in the direction of heating water/sewage treatment, water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems such as the adverse effects of vacuum flash condensers, and achieve a reduction in floor space Small size, reduced failure rate, simplified operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solutions and technical effects of the present invention will be further described below through specific embodiments and in conjunction with the accompanying drawings. It should be understood that the following embodiments are used to illustrate the present invention, but not to limit the scope of the present invention.

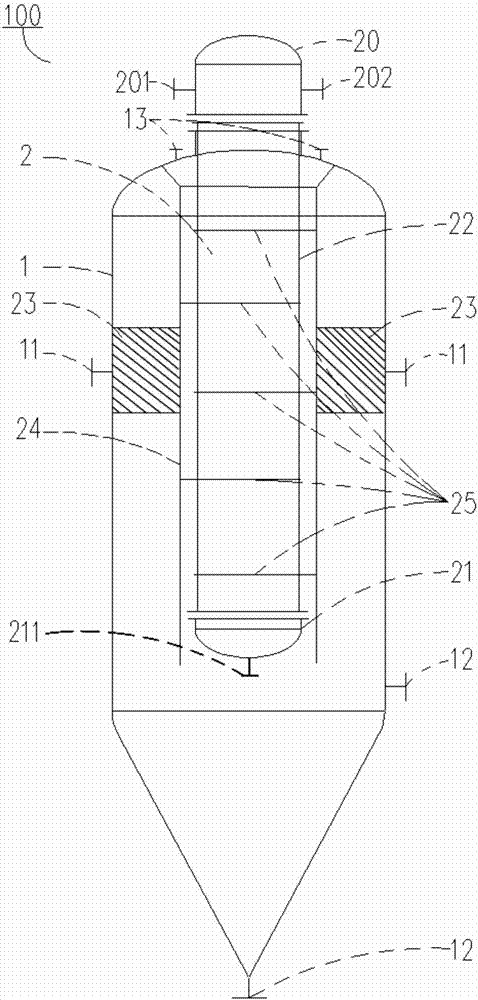

[0031] Such as figure 1 As shown, in a specific embodiment, the vacuum flash cooling device 100 includes a shell 1, a water cooling device 2 and internal components; the inside of the shell 1 is defined as an accommodating chamber for providing a flash space for water, and the top of the shell 1 The center is provided with a water cooling device interface, and the top of the shell 1 is provided with 6 flash cooling air outlets 13 around the water cooling device interface, which are equally spaced and evenly distributed with the center point of the top of the shell 1 as the center; the middle part of the side wall of the shell 1 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com