Supporting-retaining protection structure for underground continuous side wall not subjected to trough excavation, and construction method thereof

A technology for side walls and fertilizer troughs, which is used in infrastructure engineering, sheet pile walls, buildings, etc., can solve the problems of uneven settlement and deformation quality around foundation pits, difficulty in ensuring backfill quality, and increase in excavation earthwork. Overcome the limitations of site excavation conditions, is conducive to anti-corrosion protection, and saves the cost of the project

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

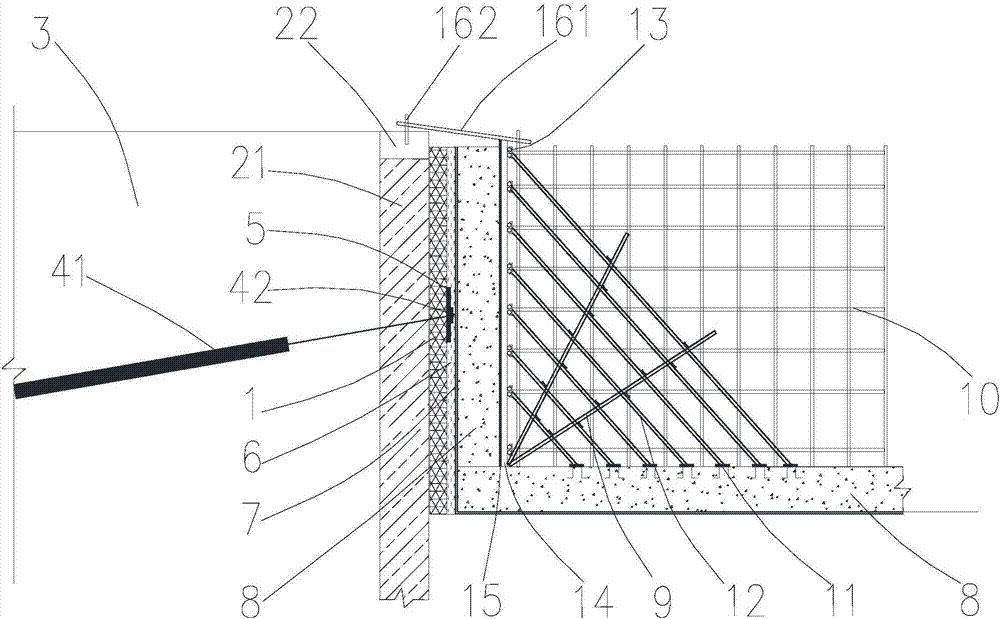

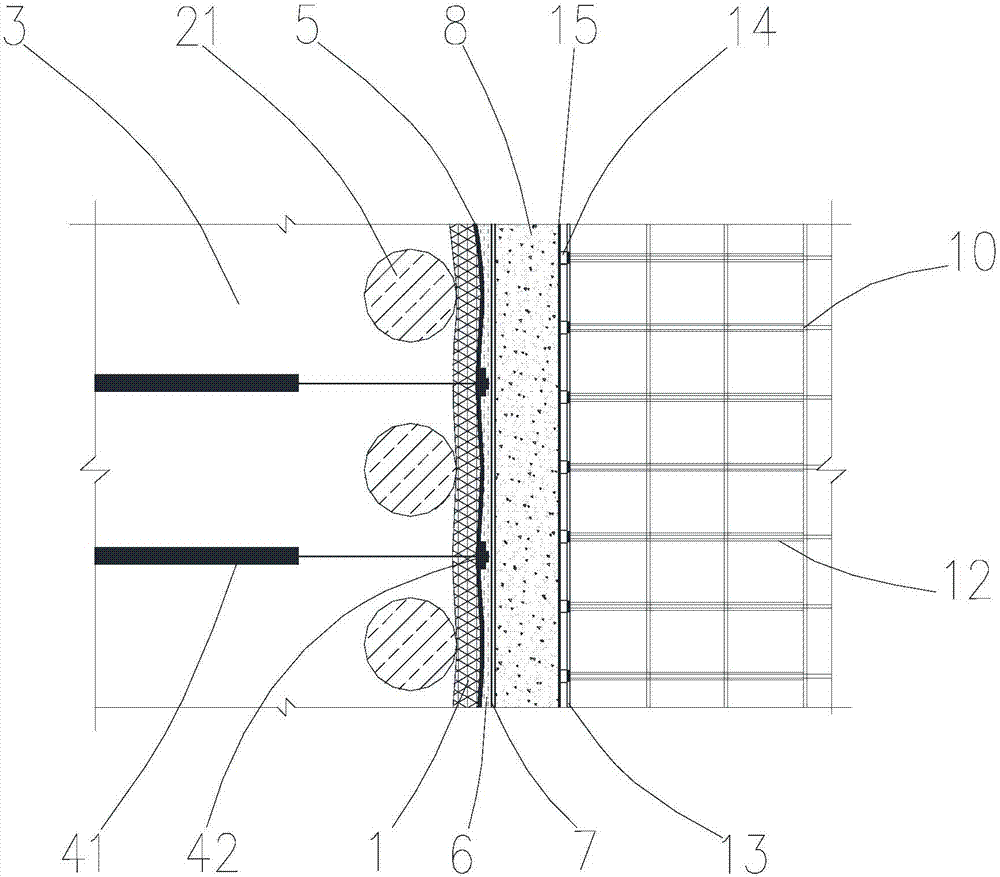

[0025] see Figure 1 to Figure 2 An underground continuous side wall support and protection structure without fertilizer groove excavation is shown, including the soil body 3 on the side wall of the foundation pit. The hanging net shotcrete layer 1 is attached to the outside of the reinforced concrete support pile 21 on the surface, and the anchor cable 41 is drilled and grouted in the middle of the soil body 3, and the anchor cable 41 is locked on the side of the hanging net shotcrete layer 1 through the anchor head 42 The strip-shaped steel plate 5 is put on and tightened, and the mortar leveling layer 6 and the waterproof coiled material layer 7 are made successively outside the hanging net shotcrete layer 1, and the waterproof coiled material layer is also made together with the bottom of the foundation pit when the waterproof coiled material layer 7 is made. 7. A reinforced concrete layer 8 is formed on the waterproof membrane layer 7. The reinforced concrete layer 8 incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com