Ceramic tile paste process

A ceramic tile and process technology, applied in the field of tile sticking technology, can solve the problems of workers' technical requirements and high sense of responsibility, and achieve the effect of reducing the setting time and bonding firmly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

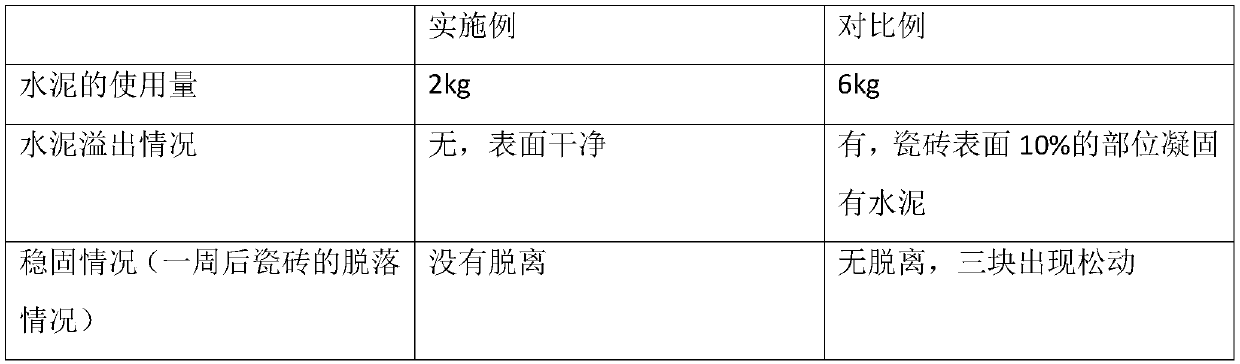

Examples

Embodiment

[0026] The pasting process of ceramic tile of the present invention comprises the following steps:

[0027] Step 1), prepare cement mortar: when preparing, the ratio of cement and sand is prepared according to 1:3;

[0028] Step 2), apply cement mortar on the center of the back of each tile to be pasted. At this time, the amount of cement used is 138.89 square centimeters; after applying the cement, use a toothed scraper to comb the cement, and the combed cement The surface is bar-toothed;

[0029] Step 3) Paste the tiles coated with cement mortar on the wall. When pasting the adjacent tiles, place the cross card vertically with the pasted tiles, and then paste the next tile, so as to align the tiles Adjust the joint gap between;

[0030] Step 4), after the tiles are laid, remove the cross card, and paste the PE protective film on the surface of the tiles. At this time, the joint gap between the PE protective film and the tiles forms a gap cavity;

[0031] Step 5), inject t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com