conjoined structure building

A technology of conjoined structure and main structure, applied in the direction of buildings, building types, building components, etc., can solve the problems of insufficient utilization of truss materials and low stress level of truss webs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

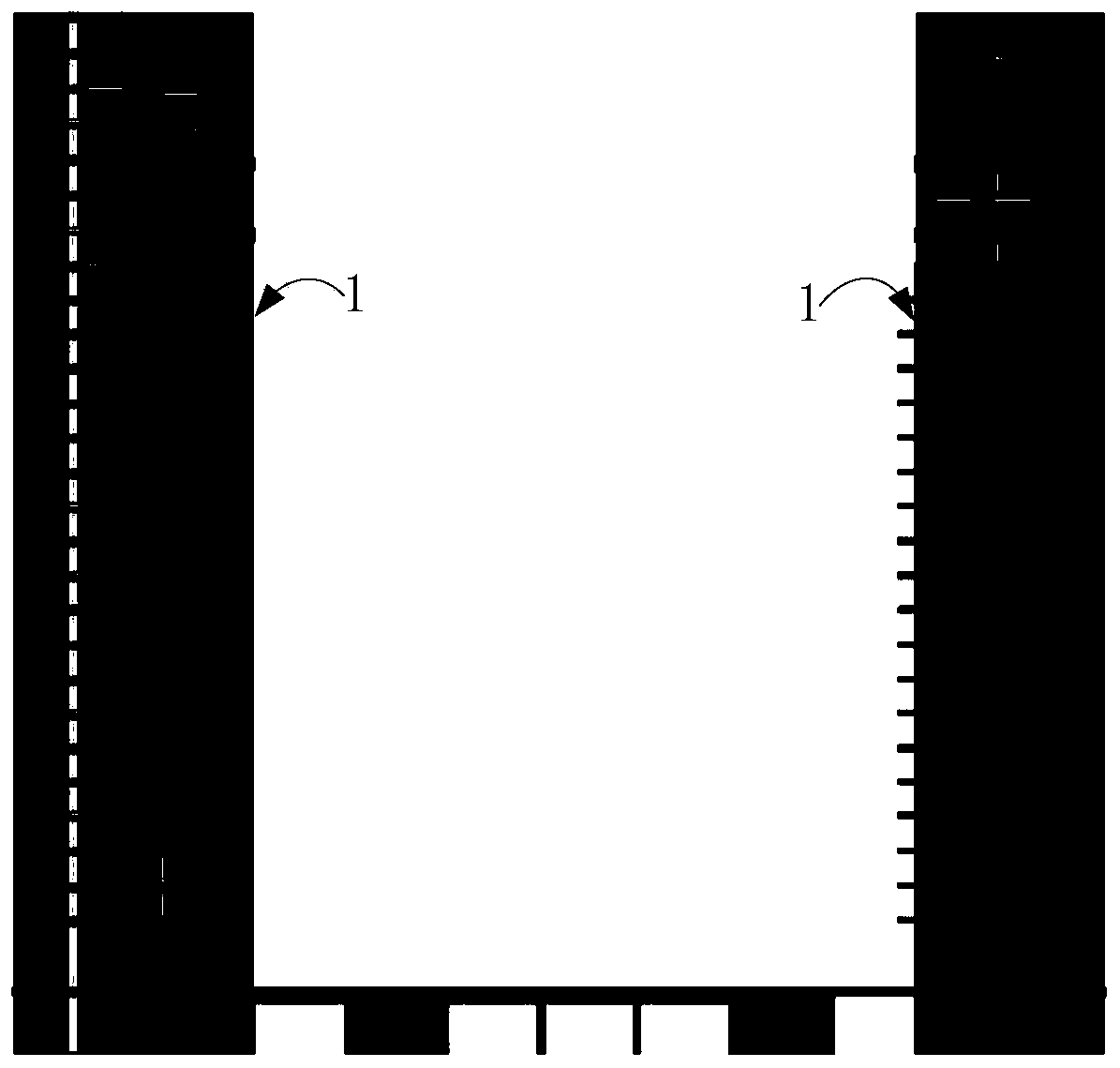

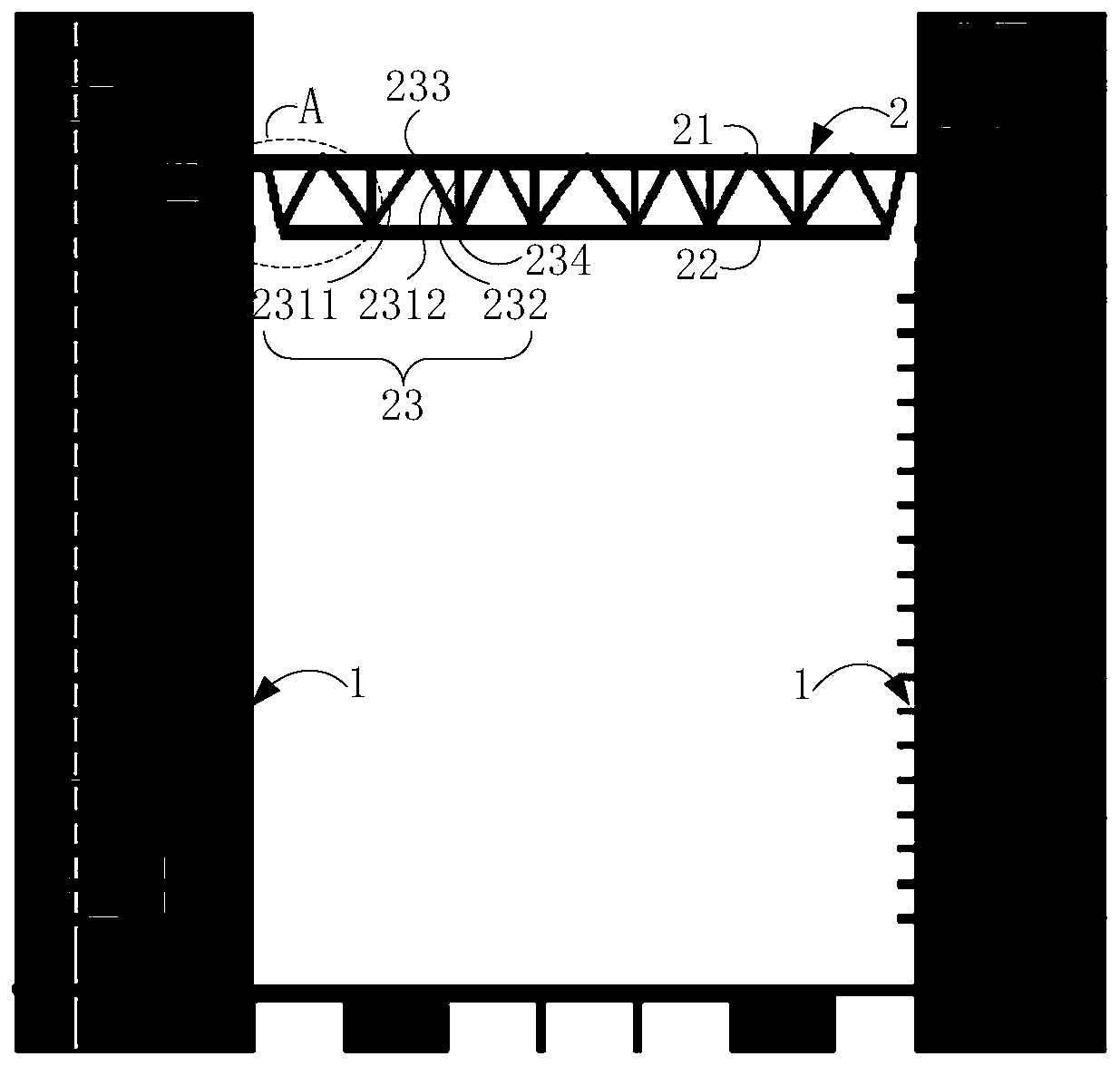

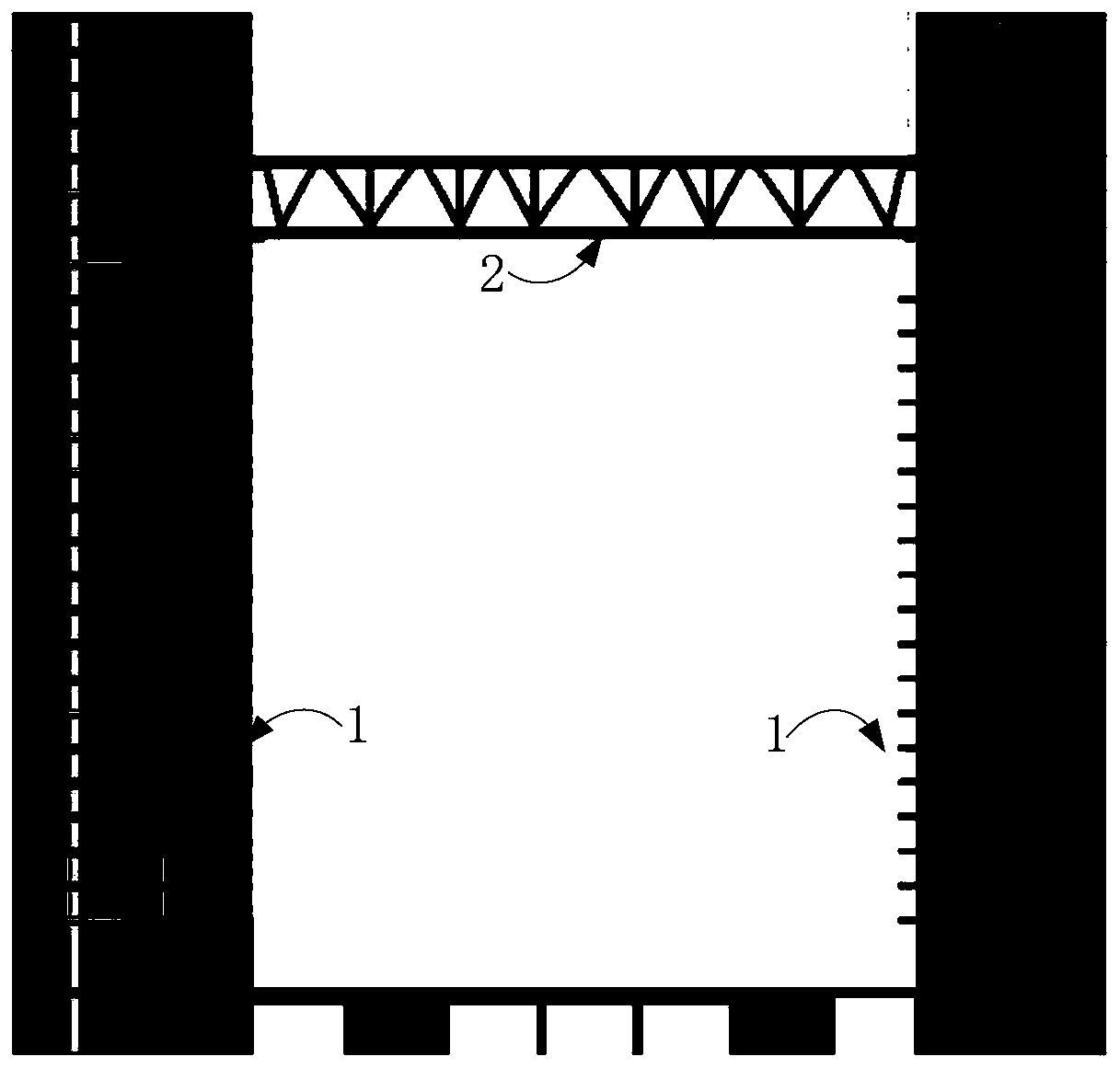

[0095] This embodiment provides a conjoined structure building, combining Figure 1 to Figure 10 As shown, the conjoined structure building includes two main structures 1 arranged at intervals, and a connecting body truss 2 fixed between the two main structures 1 . Such as figure 2 As shown, the connecting body truss 2 includes an upper chord 21 , a lower chord 22 , and a web 23 connected between the upper chord 21 and the lower chord 22 . combine Figure 1 to Figure 3 As shown, the conjoined structure building is obtained through the following construction methods:

[0096] Respectively construct the main structure 1 and the connecting body truss 2;

[0097] Hinge: connect the ends on both sides of the upper chord 21 of the connecting body truss 2 ( figure 2 middle, left and right ends) are respectively hinged with the parts to be connected on the main structure 1, and the ends on both sides of the lower chord 22 are disengaged from the parts to be connected on the main...

Embodiment 2

[0116] The difference between this embodiment and Embodiment 1 is that: Figure 11 , Figure 12 As shown, in order to strengthen the strength of the end of the upper chord 21 and the strength of the support part 24, in this embodiment, a horizontal reinforcement plate 241 is fixedly connected to the lower edge of the support part 24, and the horizontal reinforcement plate 241 is connected to the outermost two The vertical steel plates 212 jointly form the support portion 24 to increase the strength of the support portion 24 . In the subsequent construction steps, when the connecting body truss is bent and deformed, since the two vertical steel plates are connected by a horizontal reinforcement plate, the two vertical steel plates can be jointly stressed, preventing the deformation of the connecting body truss and only a single vertical steel plate In the case of more stress.

[0117] In order to further enhance the strength of the end of the upper chord 21, two transverse st...

Embodiment 3

[0119] This embodiment provides a conjoined structure building, combining Figure 13 to Figure 24 As shown, the conjoined structure building includes two main structures 1 arranged at intervals, and a connecting body truss 2 fixed between the two main structures 1 . Such as Figure 14 As shown, the connecting body truss 2 includes an upper chord 21 , a lower chord 22 , and a web 23 connected between the upper chord 21 and the lower chord 22 . The conjoined structure building is obtained through the following construction methods:

[0120] Respectively construct the main structure 1 and the connecting body truss 2;

[0121] Articulation: as Figure 14 As shown, the ends on both sides of the upper chord 21 (ie Figure 14 middle, left and right ends) are respectively hinged with the parts to be connected on the main structure 1, and the ends on both sides of the lower chord 22 are disengaged from the parts to be connected on the main structure 1 respectively;

[0122] Constr...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap