Rigid Frame Envelope Structure and Construction Method of Portal Pile Row for Highway Tunnel in Shallow Buried Mountainous Area

A technology for highway tunnels and enclosure structures, which is used in tunnels, tunnel linings, and earth-moving drilling and mining, etc., can solve problems such as hidden safety hazards and high costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0079] The embodiments of the present invention will be described in detail below according to the above-mentioned drawings.

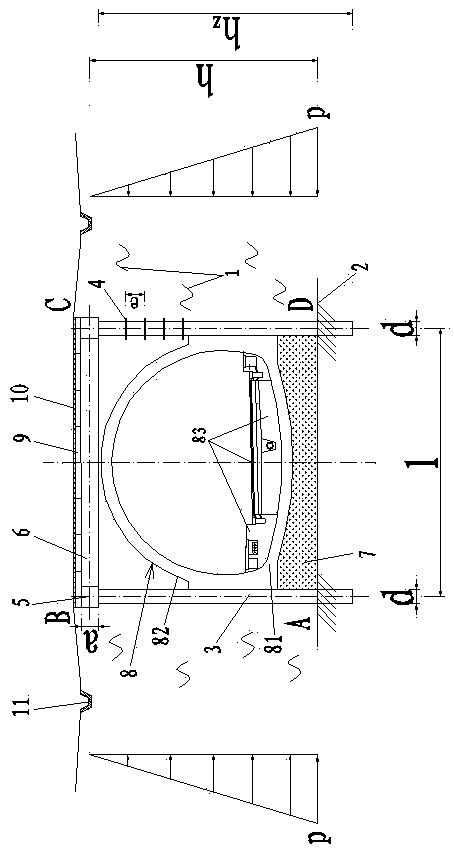

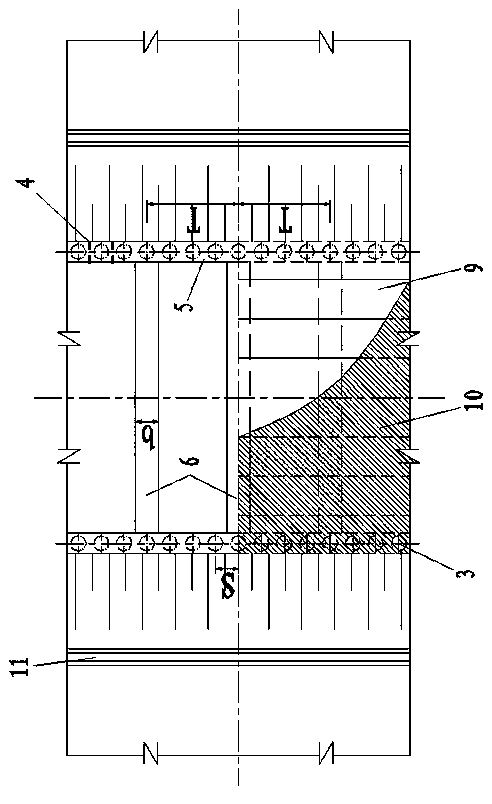

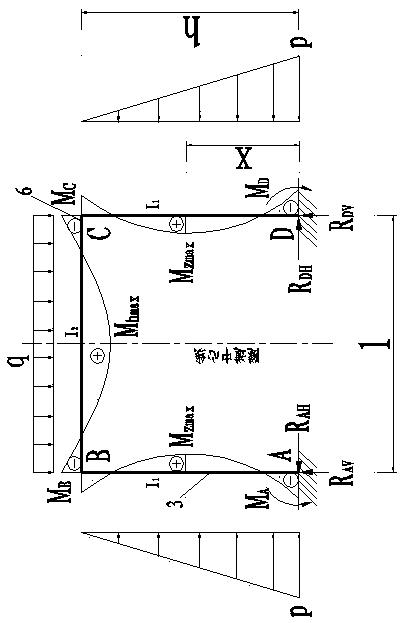

[0080] Such as Figure 1~Figure 3 As shown, 1. Bedrock, 2. Clay, 3. Bored pile, 4. Grouting pipe, 5. Crown beam, 6. Cross brace, 7. Cushion, 8. Main body of road tunnel, 81. Inverted arch, 82. Secondary lining, 83. Pavement system, 9. Cover plate, 10. Pavement layer, 11. Drainage ditch.

[0081] Portal-type pile-row rigid-frame enclosure structure and its construction method for highway tunnels in shallow buried mountainous areas, such as figure 1 , figure 2 As shown, it relates to a cover-excavation construction method for completing a shallow-buried mountain road tunnel through a portal-type pile-row rigid-frame enclosure structure.

[0082] The soil layer structure used in the above construction method mainly includes the tunnel geological structure of shallow buried clay 2 and bedrock 1 from top to bottom; The construction needs to excavate a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com