A straight-plate built-in cryopump structure with three-stage adsorption structure

A technology of adsorption structure and adsorption plate, which is applied in the direction of pumps, liquid displacement machines, machines/engines, etc., can solve the problems that the pumping speed of the cryopump cannot meet the requirements, the long-term operation of the cryopump is unfavorable, and the heat load increases, etc. The effect of shortening, convenient matching, and reducing heat load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

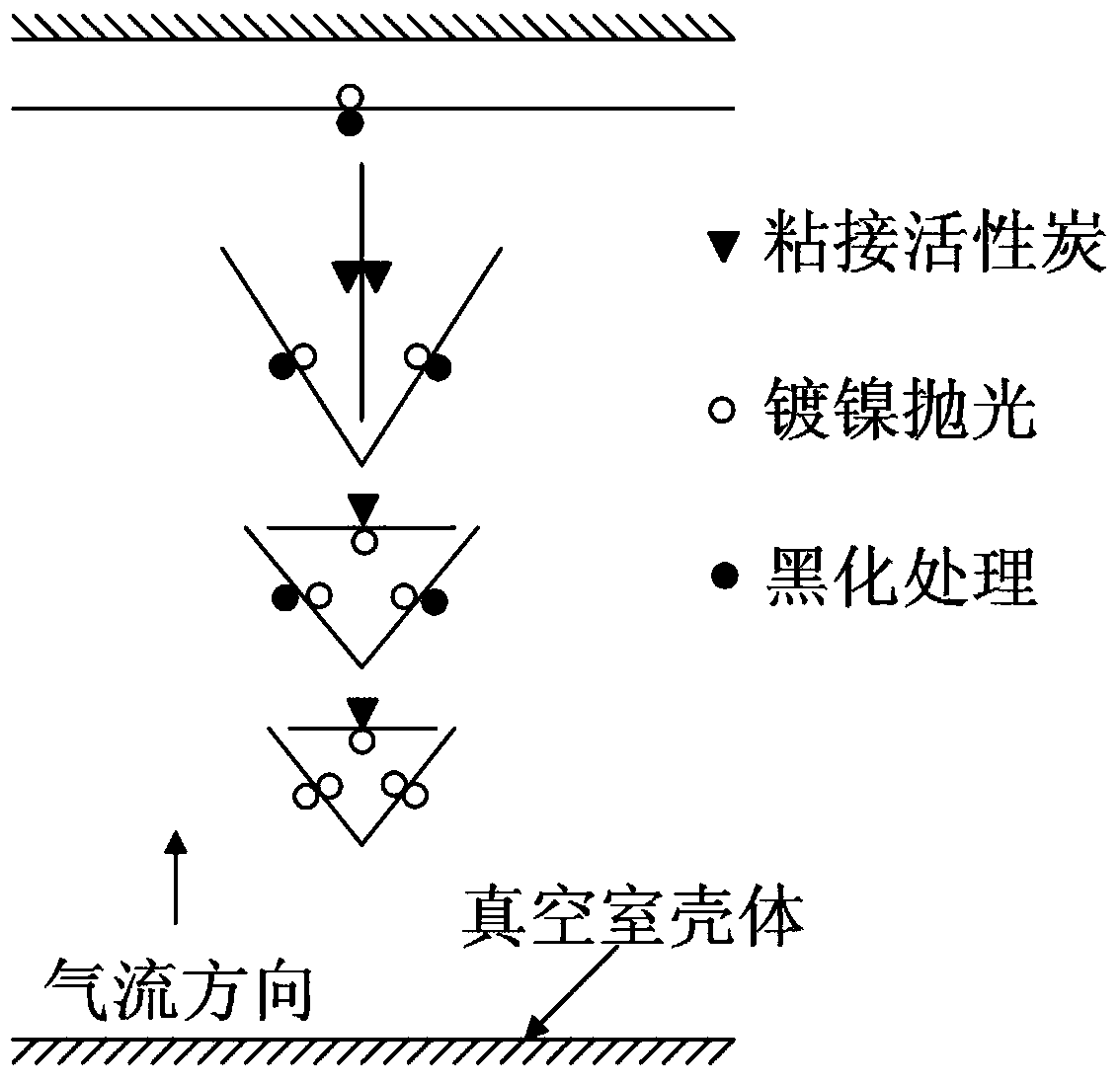

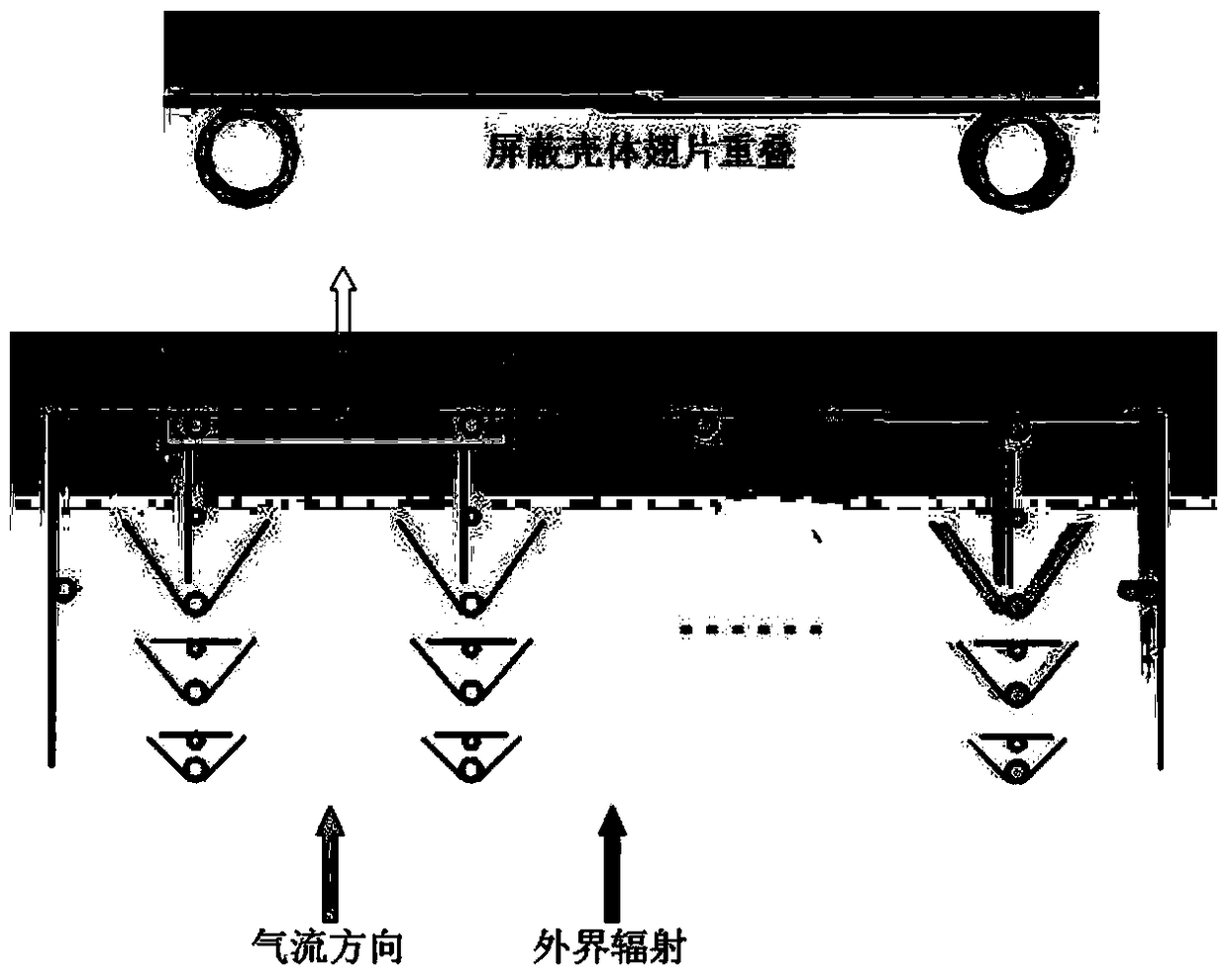

[0036] The present invention is a straight-plate built-in cryopump structure with a three-stage adsorption structure, which is applied to the vacuum differential system of the neutral beam injector in the controlled nuclear fusion experiment. The design idea of the present invention is a combination of herringbone and louver radiation shielding structures Advantages and disadvantages, considering the limited space in the vacuum chamber of the neutral beam injector, a straight-type three-stage adsorption built-in cryopump was developed. Its core is a three-stage adsorption structure, including three V-shaped radiation shielding plates and three condensation adsorption plates. . Specifically include the following aspects:

[0037] (1) The adsorption structure is composed of a radiation shielding plate and a condensa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com