Involute spline pair fretting wear testing platform

An involute spline, fretting wear technology, applied in the field of friction and wear measurement, can solve problems such as inability to apply controllable pressing force, limited simulation conditions, and inability to simulate real-time changes of rotating parts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

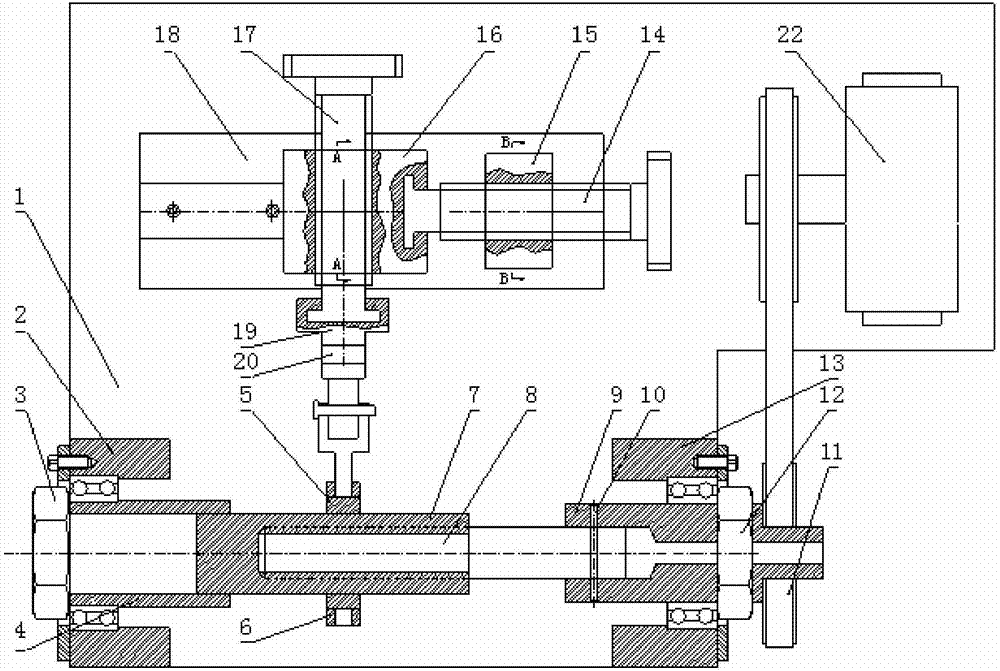

[0022] This embodiment is a fretting wear test bench for an involute spline pair.

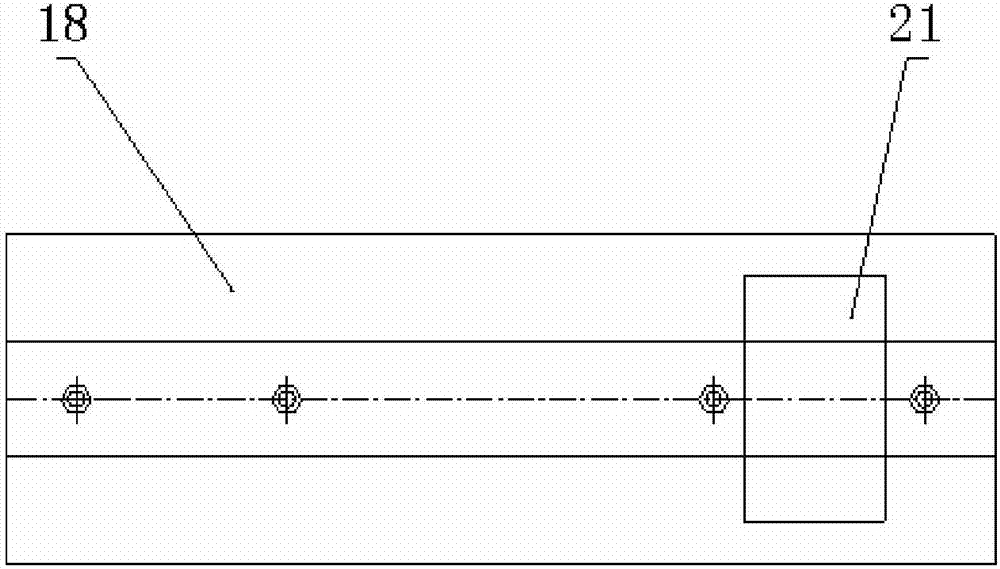

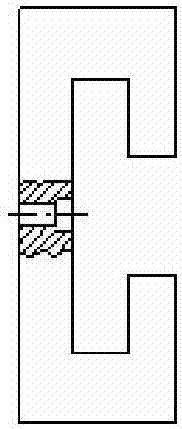

[0023] refer to Figure 1 ~ Figure 4 In this embodiment, the involute spline pair fretting wear test bench consists of a frame 1, a first fixed block 2, a driven sleeve lock nut 3, a driven sleeve 4, a wear-resistant sleeve 5, a sleeve 6, an involute Inline spline 7, involute external spline 8, driving sleeve 9, pin hole 10, driving wheel 11, driving sleeve lock nut 12, second fixed block 13, horizontal screw 14, screw seat 15, square The slide block 16, the longitudinal lead screw 17, the guide rail 18, the pull rod 19, the tension sensor 20, the square through hole 21, and the motor 22 are formed; the frame provides support for the above-mentioned components. The first fixed block 2 and the second fixed block 13 are two components with the same structure, and the first fixed block 2 and the second fixed block 13 are axially processed with round holes; the first fixed block 2 and the second f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com